Container Truck ? Over the last seventy years, the container or container has become a cargo transportation system used with accelerated intensity in the context of national and international markets, producing a significant impact on economies and the economy. Unification of cargo loading. It is then a method of transporting cargo that is easy to adopt, which involves technical, economic and administrative factors for its correct application. The requirement of port facilities, inland terminals, ships, equipment for handling, transportation: adequate land routes and the existence of a genuinely integrated world system for its regular operation.

What and why Container

In general, if the flow of cargo from its origin to its final destination is analyzed, the use of the container combines a good economy in the transport of goods.

During a total journey, a conventional import or export cargo is handled by a chain made up of the most heterogeneous technical and human team: it leaves, for example, from a factory to be subsequently transported by vehicle to the warehouses.

Related :-

Warehouse and Small Temporary Storage Rental Services

Truck Rental Services

Forklift Crane Rental Services

In each segment, within the total movement that the load undergoes, it is logically decided on the most convenient and valuable unit of the same, the most efficient means for handling, and packages of the most diverse sizes, weights, and packets are systematically received and dispatched. Degrees of brittleness and density. All of the above leads to a simple task of transferring containers becoming laborious, expensive, and inefficient work when changing modes of transport within the load’s entire route.

With the unification of containerized cargo, a radical change was obtained by accelerating the transit between the various links. The requirements for protection, size and weight are automatically determined and avoiding adjustments in the route to make adaptations. It allows the transporter’s concerns to be focused almost on the equipment and manoeuvring vehicles since their functions are limited to moving them from one point to another.

The containers have been developed on the principle of large containers. It can group and contain high volumes of cargo, generally manufactured in standard steel, aluminium, plywood with fibreglass reinforcements, with special supports in each corner.

To facilitate their fast and efficient handling, as well as the possibility of stacking them. It allows the consolidation of containers of different weights and dimensions in units that can be sealed for transport by one or more means between the place of origin and destination, without intermediate unloading. These elements have a high resistance to protect the products and have particular doors that can be closed and sealed conveniently for the user and customs regulations.

Container functions

There are several functions that a container performs, including:

Serve as a load unit for combined transport.

Serve as packaging. Containers are “additional packaging” that protects cargo and greatly contributes to smooth door-to-door service.

Facilitate stacking, for safety reasons and the storage of products in their place of origin, before being transported, during transit or at the place of destination. Streamline handling in the transport of products from the production line to the cargo terminal.

Related :-

Transport Department :- Please Click

History of Transportation :- Please Click

Importance of transport system :- Please Click

What is Container Truck in meaning Trucking Industry?

The next logical step is to standardize the containers’ size and stack them more efficiently, especially installing ships, trains, trucks and cranes in the port or building them into a single-sized specification. It was to be able to do it.

This standardization will ultimately apply to the entire global industry. This standardization is now being used throughout the world’s industry, thanks to the International Organization for Standardization (ISO) work, which established standard sizes for all containers in 1961. The two most important and most commonly used measures today are 20 feet and 40 feet.

The 20-foot container truck, called the Twenty-Foot Equivalent Unit (TEU), has become the industry standard for cargo volume and ship capacity currently measured by the TEU. The 40-foot-long container (literally 2 TEUs) has become known as the 40-foot equivalent unit (FEU) and is the most frequently used container today.

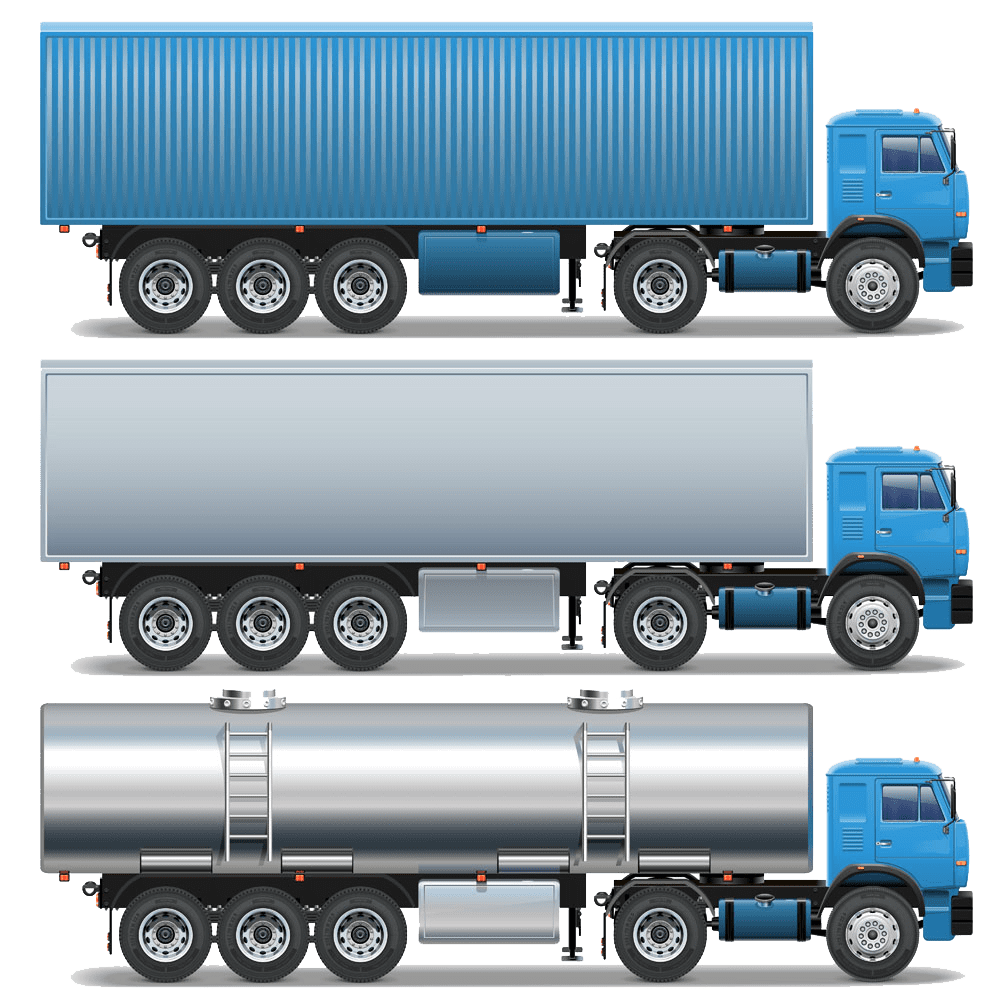

The classic container truck features a sturdy side and back closure with two easily sealable sheets. Refrigerated containers, tanks, open lids (with available roofs), and containers with empty side walls are used for specific applications such as transporting liquids and food.

Dry Storage Containers truck-

These are the standard shipping containers mentioned above and are typically used to transport dry materials 10, 20, and 40 feet long.

Flat Rack Container-

Includes foldable sides that fold flat, making it ideal for transporting boats, equipment and cars.

Side-open container-Here you can use a more extensive amount of material, which is ideal for transporting vegetables, as the container door can be fully opened on the side.

Flat rack containers are a specialized type of shipping container with collapsible sides, offering unique advantages for transporting oversized or oddly shaped cargo that wouldn’t fit inside a standard container. Here’s a breakdown of their key features and applications:

Key characteristics:

- Open sides: Unlike standard dry containers, flat racks have collapsible sides on the shorter ends, allowing cargo to extend beyond the container’s footprint.

- Variations: Available in various configurations, including full open-top (no roof), half-height sides, and collapsible sides on both ends.

- Sizes: Typically come in standard 20ft and 40ft lengths, but custom sizes can be made.

- Loading and unloading: Can be loaded from the top, sides, or ends, providing greater flexibility.

- Security: Can be secured with tarps, straps, or specialized locking mechanisms.

Applications:

- Oversized cargo: Ideal for transporting machinery, vehicles, boats, pipes, construction materials, and other large items that exceed standard container dimensions.

- Project cargo: Often used for transporting components for industrial projects, power plants, and wind turbines.

- Heavy cargo: Can handle heavier loads compared to regular containers due to their reinforced structure.

- Specialized cargo: Used for transporting unique items like artwork, sculptures, and delicate equipment requiring special handling.

- Temporary storage: Can be used for on-site storage of materials at construction sites or event venues.

Advantages:

- Versatility: Accommodate a wide range of cargo shapes and sizes.

- Flexibility: Loading/unloading from multiple sides simplifies handling of awkward or oversized items.

- Cost-effectiveness: Can be more cost-efficient than chartering specialized transport for oversized cargo.

- Security: Options for securing cargo ensure safe and secure transit.

Disadvantages:

- Limited protection: Cargo is exposed to elements compared to enclosed containers, requiring additional protection measures.

- Regulations: May require special permits for oversized cargo depending on route and weight.

- Loading/unloading complexity: Loading and securing oversized cargo can be more challenging.

- Higher insurance costs: Insurance premiums might be higher compared to standard containers.

Choosing the right flat rack container:

- Cargo size and weight: Ensure the container size and weight capacity align with your cargo needs.

- Loading requirements: Consider the most convenient loading/unloading method for your specific cargo.

- Security needs: Choose appropriate securing options based on the value and sensitivity of your cargo.

- Route and regulations: Verify if any special permits or approvals are required for your specific route and cargo.

Overall, flat rack containers offer a valuable solution for transporting oversized or complex cargo, providing flexibility, cost-effectiveness, and diverse applications. Understanding their characteristics, advantages, and limitations is crucial when deciding if this type of container is the right choice for your specific needs.

Open Containers:

According to the title, these containers have no roof and can transport goods of all heights, including logs and machines.

Refrigerated container:

For food or pharmaceutical products.

Refrigerated container transportation, also known as reefer transportation, is a specialized form of containerized shipping used to transport perishable goods that require precise temperature control throughout their journey. These containers are equipped with refrigeration units that maintain specific temperatures, ensuring the freshness and quality of the cargo.

Here are some key characteristics of refrigerated container transportation:

- Temperature control: Reefer containers can maintain a wide range of temperatures, from -25°C to 25°C, depending on the specific needs of the cargo. This allows for the transport of a variety of perishable goods, such as fruits, vegetables, meat, seafood, pharmaceuticals, and even vaccines.

- Intermodal capabilities: Reefer containers can be seamlessly transferred between different modes of transport, such as ships, trucks, and trains, without compromising the temperature control of the cargo. This flexibility makes them a valuable tool for global trade.

- Monitoring and control: Modern reefer containers are equipped with advanced monitoring and control systems that allow real-time tracking of the temperature inside the container. This allows for quick intervention if any problems arise, such as a power outage or malfunctioning refrigeration unit.

Benefits of using refrigerated container transportation:

- Reduced spoilage: By maintaining consistent temperatures, reefer containers help to reduce spoilage and waste of perishable goods. This can lead to significant cost savings for businesses and ensure that consumers have access to fresh, high-quality products.

- Wider market reach: Reefer containers allow businesses to transport perishable goods over long distances and to new markets that were previously inaccessible. This can help to expand business opportunities and increase profits.

- Improved food security: Reefer containers play a vital role in ensuring food security by transporting essential food items to areas where they are needed most.

Challenges of using refrigerated container transportation:

- Cost: Reefer containers are more expensive to purchase and rent than standard dry containers. Additionally, the cost of electricity to power the refrigeration units can be significant.

- Complexity: Operating and maintaining reefer containers requires specialized knowledge and skills. This can be a challenge for businesses that are not familiar with this type of transportation.

- Regulations: There are a number of regulations that govern the transportation of perishable goods, which can add to the complexity of using reefer containers.

Overall, refrigerated container transportation is a valuable tool for businesses that need to transport perishable goods. However, it is important to be aware of the costs, complexity, and regulations involved before using this type of transportation.

Container Truck vehicles use

Container shipments are categorized according to the number of final recipients.

FCL (Full Container Load):

Full load container. That is if one recipient needs to receive the goods, regardless of whether they have reached the maximum weight or capacity. This type of shipment is usually preferred by those who have many items to send to a single recipient.

LCL (Less than Container Load):

A partially loaded container when the container is shipped using non-exclusive use. In this case, the rental can be arranged to serve multiple recipients.

If the goods to be shipped are insufficient to fill a standard container, the package will be grouped with other batches of the same destination at the container loading station.

Container shipping is heavily used in global logistics (for the differences and everyday aspects of different shipping methods. That’s why An important port is a dedicated terminal for container loading and unloading and transportation by truck. Some ports are so-called hubs, the areas with the highest concentration of containers, especially on domestic or international routes to and from Southeast Asia, Europe and North America.

What if you need to send something that is out of shape, the so-called exceptional transport? There is a unique solution for this type of move. For more information on this subject, see the article SI-Log Network: All Solutions for Exceptional Transportation.

Container Truck vehicles advantage

Low-cost, high-speed shipping:

A container truck is a vehicle that documents all the goods it contains, so information is detailed outside the container to be shipped quickly to its destination. This significantly simplifies customs clearance. .. For both senders and recipients, containerization also has significant economic advantages over other means of transporting goods.

Safe and energy-efficient means of transporting cargo:

Once sealed, the container provides vital protection for goods as it allows for a physical barrier to bad weather, temperature changes, fire, theft and shock in transit. To do. Therefore, containers significantly reduce the risk of deterioration, loss, and theft found in inland transportation. In addition, sea transport consumes less energy than other freight transport methods.

Versatile and flexible means of transportation:

Container shipping can be used to transport large quantities of goods to the other side of the world and transport small goods over short distances. Container transportation can also be used to transport both dangerous liquid substances such as hydrocarbons and chemicals and solid products such as food (wheat, flour, livestock feed, etc.), so it is used for transporting cargo.

Container Truck vehicles disadvantage

Physical restrictions.

This has a specific cost. Containers provide some security to the condition of goods by protecting them from temperature changes, fires and theft. Still, there are certain physical restrictions, such as high temperatures and lack of internal ventilation. It may cause damage to the container. Therefore, this mode of transport has the disadvantage of requiring precautions against the package’s drying and condensation inside the container. Therefore, these precautions against possible damage may require costly special packaging and special container shipping insurance.

Product characteristics

In some cases, restrictions on product characteristics may interrupt the container shipping plan. Packages may be rejected because the goods’ weight, volume, and dimensions may not match those of the standardized container. However, it is possible to do business with suppliers who adjust their products’ dimensions and packages for containerization.

Fact about Container Truck vehicles

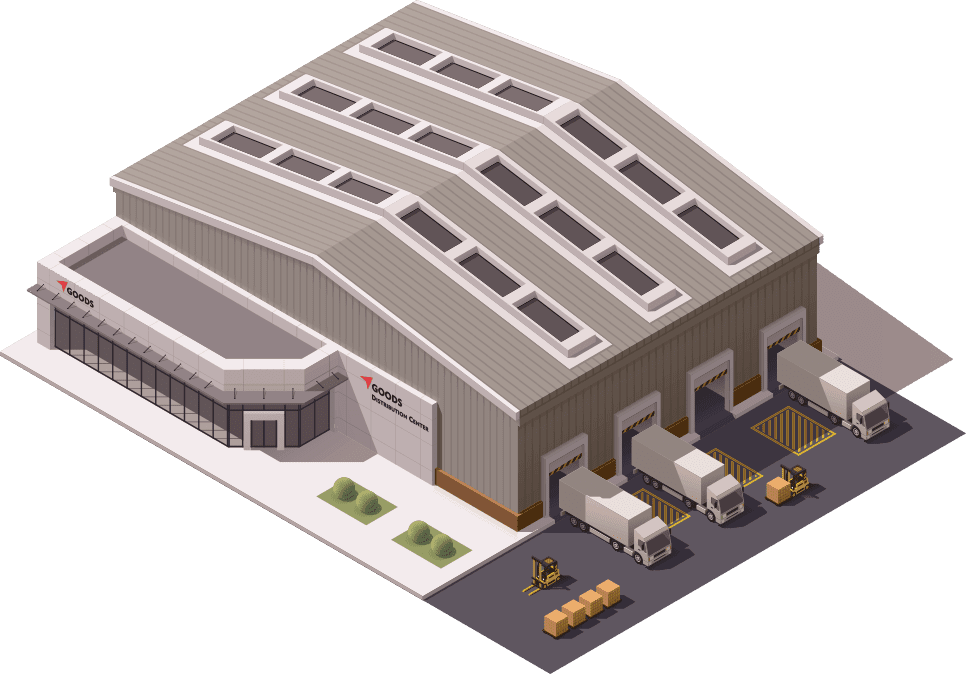

Logistics centres play an essential role in transportation logistics today, and this importance continues to grow, especially when it comes to management and handling. But most importantly, it’s not just the large transportation logistics hubs that often act as the primary gateway to the import and export of goods.

There are also much smaller but equally important logistics centers, such as the Transport Logistics Center for Freight Networks. When the hub gets crowded, the containers are later collected and transported to smaller terminals. Therefore, it is imperative to constantly monitor the cargo so that the exact location of the load can be tracked at any time.

What is container truck transportation in shipping industry ?

A container stores goods to facilitate their transport from one point to another, whether by land, river, sea, air or in combination.

The size of the containers is variable, thus being able to adapt to multiple transport needs. All measurements are standardized worldwide by the respective ISO standards.

• The width of the containers is almost 2.5 meters, while their height is close to 3 meters.

• The length of the containers ranges from 2.44 to 16 meters, the most frequent being 6 meters (with a surface area of 32 m 3 ) and 12 meters (with a surface area of 66 m 3 ).

Regarding the transport of containers, all of them must be identified with an 11-digit alphanumeric code, revealing who their owner is and what type of container it is.

According to the means used to carry out the container transport, we can classify it as follows:

• Land container transport (by truck or train): it is the most frequent for medium and short distances.

• Container transport by air (by plane): It is the fastest and most expensive. It is used for the international movement of small and light goods.

• Maritime container transport (by ship): It is used for the international transfer of large and heavy goods, being slower and cheaper than air.

What are the advantages of container shipping?

1.As the containers are a watertight unit, they keep your cargo safe from the weather or other damages, thus guaranteeing its safety (as it is not handled during transhipments).

2. Container transport stands out for its versatility: it adapts to all types of goods and means of transportation (air, sea, land) without the need to change the container during transhipments.

3. Although there are different classes and sizes of containers, their ISO homologation significantly streamlines administrative procedures since it implies their unification globally.

4. Container transport represents considerable savings, as it is always cheaper than transporting goods in bulk.

5. Ecological: when their useful life (7 to 14 years) has already been amortized, the containers can be reused as modular buildings (offices, warehouses, training centres). It is known as cargo load.

Quality container transport

Don’t worry and put the vehicle of your goods in the best hands.

• Express transport service (in 24 hours) or urgent (in less than 48 hours) to any point.

• Transportation service of all types of merchandise: vehicles (cars, trucks, trailers, buses), pallets, dry cargo, perishable inventory. Adapting to the kind of load and complying with all regulations.

• All the services you need: we design transport solutions that best suit you, storage of merchandise, we carry out total management of your transport

• The best means at your disposal: in addition to complying with all the necessary certificates and permits, we have a complete fleet of highly advanced vehicles and an expert and highly qualified staff.

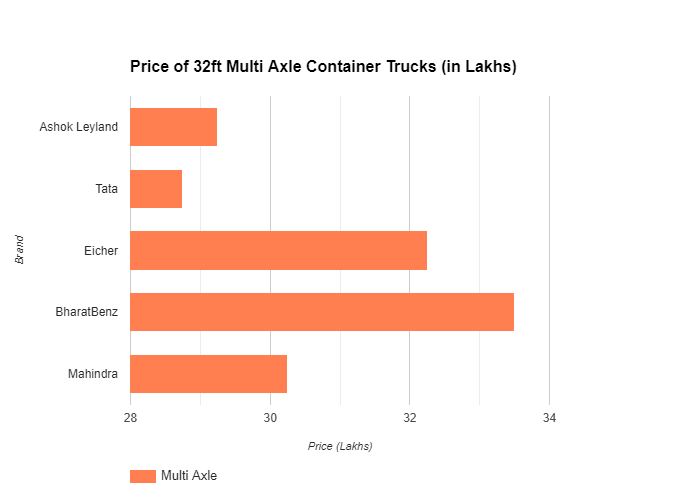

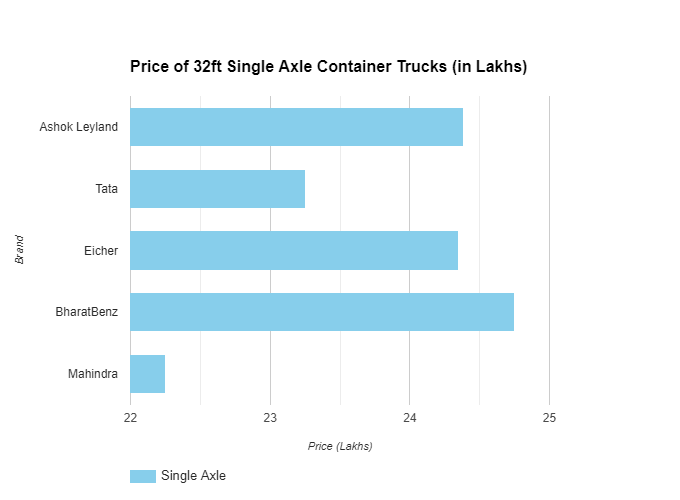

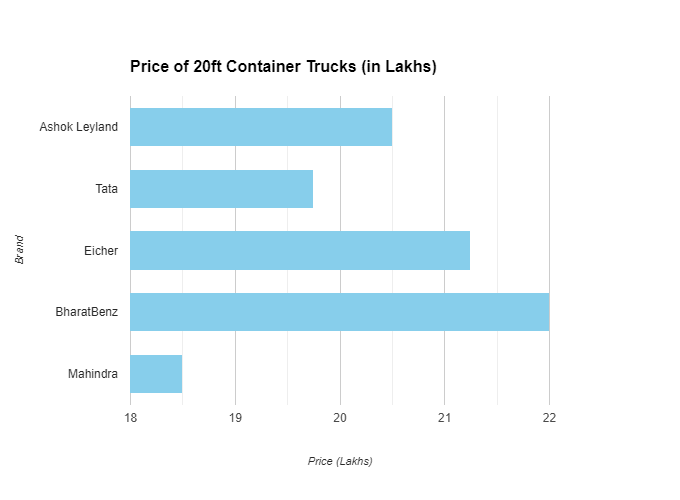

Worldwide Top Best Container Trucks Manufacturing Companies :-

- Ashok Leyland

- BharatBenz

- Cat

- Daimler AG (Mercedes-Benz)

- Freightliner

- Unimog

- Western Star

- Fuso

- Isuzu

- Navistar International

- Dongfeng

- Tata

- Volvo

- Mack

- Renault

- UD Nissan

- Volkswagen Group

- MAN

- Scania

- Caminhões e Ônibus

- Hino

- Paccar

- DAF

- Kenworth

- Peterbilt

- Iveco

Related :-

Barge Rental Services

Specialist Offshore Project Working Projects

Specialist Onshore Project Working Projects

Conclusion

Container truck as Road transport is the most preferred and popular mode of transport in the supply chain and is used by suppliers and businesses. Shipping companies offer scheduled delivery dates and next-day delivery services, depending on demand. All types of cargo, packed or grouped in containers, are transported by road from one location to another, even if sea or air transport is planned.

ABCC India Project Cargo Corporation Provide All Types CONTAINER GOODS CARRIER TRUCKS on Rent as Per Size ,Working Location ,Quantity and Quality Service Demand

ABCC India Project Cargo Corporation provides all types of container goods carrier trucks on rent. Here are some of the types of container trucks that they offer:

- 20-foot container trucks: These trucks are designed to carry a standard 20-foot shipping container. They are typically used for transporting goods that are not too heavy or bulky.

- 40-foot container trucks: These trucks are designed to carry a standard 40-foot shipping container. They are larger and more powerful than 20-foot container trucks, and they can be used to transport heavier and bulkier goods.

- High cube container trucks: These trucks are designed to carry high cube shipping containers. High cube containers are taller than standard shipping containers, and they can be used to transport goods that are taller than standard shipping containers.

- Refrigerated container trucks: These trucks are designed to carry refrigerated shipping containers. Refrigerated shipping containers are used to transport goods that need to be kept at a certain temperature, such as food and pharmaceuticals.

- ABCC India Project Cargo Corporation also offers a variety of rental options to fit the needs of their customers. Customers can rent trucks by the day, week, or month, and they can also choose to add on additional services such as insurance and delivery.

- To rent a container truck from ABCC India Project Cargo Corporation, customers can visit their website or call their customer service line. They will need to provide information about the type of truck they need, the length of time they need it for, and their desired delivery location.

- ABCC India Project Cargo Corporation is a reliable and experienced provider of container goods carrier trucks. They have a fleet of trucks that can meet the needs of any customer, and they offer a variety of rental options to fit any budget.

ABCC India Project Cargo Corporation is a company that specializes in providing container truck transportation and emergency storage services all over India. They have a wide range of trucks and trailers that can accommodate different types of cargo, including flat rack containers, oversized cargo, and project cargo.

ABCC India Project Cargo Corporation has a team of experienced professionals who are committed to providing their customers with the best possible service. They offer a variety of services, including:

- Container truck transportation: ABCC India Project Cargo Corporation can transport your containers to any destination in India. They have a fleet of trucks and trailers that can accommodate any size or type of container.

- Emergency storage: If you need to store your cargo on short notice, ABCC India Project Cargo Corporation can help. They have a network of warehouses and storage facilities throughout India.

- Heavy haulage: ABCC India Project Cargo Corporation can transport your oversized or heavy cargo safely and efficiently. They have the experience and equipment needed to handle even the most challenging loads.

- Project cargo: ABCC India Project Cargo Corporation can handle all of your project cargo transportation needs. They have the expertise and resources to move your cargo safely and on time.

ABCC India Project Cargo Corporation is a reliable and experienced company that can help you with all of your container truck transportation and emergency storage needs. They offer a wide range of services and are committed to providing their customers with the best possible service.

Here are some additional things to consider when choosing a container truck transportation and emergency storage company:

- Reputation: Choose a company with a good reputation for safety and reliability.

- Experience: Choose a company with experience in handling your type of cargo.

- Price: Get quotes from multiple companies before making a decision.

- Insurance: Make sure the company has adequate insurance to cover your cargo in case of damage.

Click and follow our page for regular upgraded and latest news about Container Truck Transportation Service :- Please Click

Public Frequently asked questions (FAQ)

Which truck manufacturers’ trucks are preferred for making container trucks?

Container trucks are used for fast, efficient, safe delivery of goods. fuel consumption is also seen in an important way. From this point of view, the container trucks that we see around us are as follows. :- Eicher, Isuzu, Ashok Leyland , Hino Etc….

Which part of a container truck wears out more quickly?

The parts of a container truck that wear out more quickly depend on several factors, including:

Operating conditions:

Road quality: Rough and uneven roads put more stress on suspension components, tires, and the chassis.

Terrain: Frequent driving on hilly or steep terrain strains the engine, brakes, and drivetrain.

Climate: Extreme temperatures and weather conditions can accelerate wear and tear on various components, such as tires, seals, and engine parts.

Driving habits:

Frequent braking and acceleration: This puts extra strain on the brakes, tires, and drivetrain.

Overloading: Exceeding the truck’s weight capacity puts stress on the entire vehicle, leading to faster wear and tear.

Improper maintenance: Skipping regular maintenance or using low-quality parts can lead to premature wear and failure.

Specific components:

Tires: These are constantly exposed to friction and road hazards, making them one of the fastest-wearing parts.

Brakes: They experience significant wear during frequent stops and starts.

Suspension components: Bushings, shocks, and other suspension parts wear out due to constant movement and road impacts.

Engine: While generally built to last, prolonged operation under harsh conditions or improper maintenance can lead to wear and tear.

Generally, tires, brakes, and suspension components tend to wear out more quickly on container trucks due to their constant exposure to stress and harsh operating conditions. However, the specific parts that wear out fastest can vary depending on the factors mentioned above.

Here are some additional points to consider:

Regular maintenance: Following a proper maintenance schedule and using high-quality parts can significantly extend the lifespan of various components.

Driving style: Adopting a smooth and responsible driving style can minimize wear and tear on the truck’s systems.

Monitoring: Regularly inspecting the truck and paying attention to warning signs of wear can help prevent unexpected breakdowns and costly repairs.

By understanding the factors that influence wear and tear and practicing proper maintenance and driving habits, you can optimize the lifespan of your container truck and its components.

Which container trucks are most commonly used?

The most commonly used container trucks depend on various factors, including:

Region: Preferences can differ based on the dominant players in a specific market. For instance, in India, Tata Motors and Eicher are popular choices, while in the US, Kenworth, Peterbilt, and Freightliner are widely used.

Container size and application: Different truck sizes and configurations cater to specific container dimensions and intended use. A 22 ft container might require a different truck from a 40 ft container. Flatbed trucks are suitable for oversized cargo, while refrigerated trucks are necessary for temperature-sensitive goods.

Regulations: Local regulations might dictate the type and size of trucks allowed on specific roads or carrying certain cargo.

Here’s a breakdown of some commonly used container trucks by size:

Small containers (10-20 ft):

Pickup trucks: Often used for short-distance deliveries or within urban areas.

Cargo vans: Offer enclosed space for smaller shipments.

Small box trucks: Provide more cargo capacity than vans, suitable for regional deliveries.

Medium containers (20-30 ft):

20/22/24 ft trucks: Versatile and widely used for regional and long-distance hauling.

32 ft SXL/MXL trucks: Popular in India and other regions for medium-sized cargo transportation.

Large containers (40 ft):

40 ft trailers: Standard size for international shipping and long-distance hauls.

53 ft trailers: Primarily used in North America for domestic shipments.

What is the fare per kilometer of a container truck?

If we talk about transportation of more than 500 km, then the fare of container truck is Rs.95 per kilometer.

What is the safe life of a container truck?

The safe life of a container truck depends on several factors, making it difficult to give a single, definitive answer. Here’s what you need to consider:

Factors impacting safe life:

Truck usage: Frequency of use, load weight, and operating conditions (terrain, road quality, climate) significantly impact wear and tear.

Maintenance: Regular and proper maintenance with high-quality parts extends the lifespan.

Driving habits: Smooth and responsible driving minimizes wear and tear.

Manufacturer and model: Different brands and models have varying build quality and durability.

Estimated ranges:

While a specific lifespan is impossible to pinpoint, here are some general estimates based on different sources:

Years: 5-10 years is a common range, but well-maintained trucks can last up to 15 years.

Mileage: 500,000 – 1,000,000 miles (800,000 – 1,600,000 km) is a typical range, but again, individual cases can vary.

Important considerations:

Safe life vs. economic life: The “safe life” refers to when the truck can still operate safely, but the “economic life” considers when repairs and maintenance become too expensive, making replacement more cost-effective. This can be sooner than the safe life.

Legality: Many countries have regulations on truck age and safety inspections, which can influence how long a truck can be operated legally.

Recommendations:

Regular inspections: Conduct thorough inspections regularly to identify potential issues and address them promptly.

Maintenance schedule: Follow the manufacturer’s recommended maintenance schedule and use high-quality parts.

Monitor performance: Pay attention to changes in performance, fuel efficiency, and warning signs of wear and tear.

Consult professionals: Seek advice from experienced mechanics and fleet managers to assess your truck’s specific safe life.

Remember, these are just general guidelines. The best way to determine the safe life of your container truck is to consult with professionals and carefully monitor its condition and performance based on your specific usage and maintenance practices.

Container trucks available everywhere?

The availability of container trucks in India varies depending on several factors, including:

Location: Container trucks are more readily available in major cities and industrial hubs like Mumbai, Delhi, Chennai, Kolkata, and Pune, where there is a higher demand for freight transportation. In smaller towns and rural areas, availability might be limited.

Truck size and type: Smaller trucks like 20ft container trucks are generally more common and easier to find than larger ones like 40ft trailers. Specialized container trucks like refrigerated trucks or flatbed trucks might have limited availability in certain regions.

Seasonality: During peak seasons or periods of high demand, container truck availability can tighten, and prices might increase.

Here’s a more detailed analysis of container truck availability in different parts of India:

North India: Major cities like Delhi, Chandigarh, and Jaipur have good availability of container trucks. However, availability might be lower in smaller towns and hilly regions like Himachal Pradesh and Jammu & Kashmir.

South India: Major cities like Chennai, Bangalore, and Hyderabad have good availability. Additionally, coastal areas with major ports like Kochi and Visakhapatnam have easy access to container trucks.

West India: Mumbai, Pune, and Ahmedabad have good availability. However, smaller towns and rural areas in states like Rajasthan and Gujarat might have limited options.

East India: Kolkata and other major cities have decent availability. However, the northeast region, with its challenging terrain and limited infrastructure, might have lower availability.

Overall, while container trucks are generally available in most parts of India, their accessibility can vary depending on location, truck size, seasonality, and other factors. It’s always recommended to contact multiple transportation companies and compare quotes before booking a container truck for your specific needs.

What is a container transport?

Container transport refers to the movement of goods in standardized, reusable metal boxes called containers across various modes of transportation, including:

Ships: Primarily used for international maritime transport, container ships carry large numbers of containers stacked efficiently, maximizing cargo capacity.

Trucks: Containers can be transported by trucks on highways and roads for shorter or inland distances.

Trains: In some regions, container transport utilizes rail networks for efficient and cost-effective long-distance movement.

Key characteristics of container transport:

Standardization: Containers come in specific sizes (most commonly 20ft and 40ft) and follow international standards (ISO), ensuring compatibility across different transport modes.

Intermodality: The same container can be seamlessly transferred between ships, trucks, and trains without unloading the goods inside, simplifying logistics and reducing handling costs.

Efficiency: Containerization allows for efficient packing, loading, and unloading, leading to faster turnaround times and lower transportation costs.

Security: Containers offer secure and weatherproof protection for cargo during transport.

Benefits of container transport:

Reduced costs: Standardization and intermodality contribute to significant cost savings compared to traditional methods like break-bulk cargo.

Increased efficiency: Faster loading, unloading, and intermodal transfers lead to quicker delivery times.

Improved security: Cargo remains secure within sealed containers throughout the journey.

Wider reach: Container transport facilitates global trade by enabling efficient movement of goods over long distances.

Overall, container transport has become the dominant mode for international and domestic freight movement due to its efficiency, cost-effectiveness, and security. It plays a crucial role in global trade and supply chains, enabling the seamless movement of goods across borders and continents.

What is the container on a truck called?

The container itself doesn’t have a separate name when mounted on a truck. It simply retains its standard name, which is intermodal container or shipping container. However, there are other terms associated with the combination of a container and a truck:

Container truck: This refers to the entire truck assembly, including the chassis, wheels, and the container itself.

Container chassis: This is the part of the truck specifically designed to carry the container. It’s essentially a skeletal frame with wheels and locking mechanisms to secure the container.

Flatbed truck: While not exclusively used for containers, flatbed trucks can also transport them. These trucks have a flat, open platform where the container is secured.

So, depending on the context, you can use any of these terms to describe the container on a truck:

If you’re talking about the box itself, it’s simply a container.

If you’re referring to the entire truck and trailer combination, it’s a container truck.

If you’re focusing on the specific frame holding the container, it’s a container chassis.

And if it’s on a flat platform with no sides or roof, it’s on a flatbed truck.

How can containers be transported?

Containers are incredibly versatile and can be transported using a variety of methods, each with its own advantages and disadvantages:

Sea:

Container ships: This is the most common way to transport containers internationally. Large vessels carry thousands of containers stacked efficiently, offering economies of scale and long-distance capabilities.

Advantages: Cost-effective for bulk shipments, vast global network of ports, efficient loading/unloading with cranes.

Disadvantages: Slower than other modes, vulnerable to weather delays, limited inland reach.

Land:

Trucks: Trucks offer flexibility and can transport containers directly to their final destination, especially for shorter distances or inland locations.

Advantages: Door-to-door delivery, suitable for smaller shipments, faster than ships.

Disadvantages: Higher cost per kilometer compared to ships, limited cargo weight and size, potential traffic congestion.

Rail:

Trains: Rail transport offers a balance between cost and speed, particularly for long-distance inland routes.

Advantages: More environmentally friendly than trucks, efficient for large volumes, can handle heavier loads than trucks.

Disadvantages: Limited network reach compared to roads, slower than trucks for short distances, requires specialized terminals for loading/unloading.

Air:

Cargo planes: While less common, air freight is the fastest option for time-sensitive or high-value cargo.

Advantages: Fastest transport mode, suitable for urgent shipments, secure handling.

Disadvantages: Most expensive option, limited cargo weight and size, small network compared to other modes.

Intermodal:

Multimodal transport: This involves combining different modes (e.g., ship-to-truck) to leverage the strengths of each and optimize costs and speed.

Advantages: Flexible and customizable, can adapt to specific needs, potentially cost-effective depending on route and distance.

Disadvantages: Requires careful planning and coordination between different transport providers, potential delays at transfer points.

The choice of how to transport containers depends on several factors, including:

Distance: For long distances, ships are often the most cost-effective option.

Time sensitivity: Air freight is ideal for urgent shipments, while ships offer the slowest transit times.

Cost: Trucks are generally more expensive than ships but cheaper than air freight.

Cargo size and weight: Some modes have limitations on container size and weight.

Infrastructure: The availability of ports, rail networks, and suitable roads will influence the feasible options.

By considering these factors and understanding the strengths and limitations of each transport method, you can choose the most suitable way to move your containerized cargo.

What goods are transported in containers?

An incredibly vast array of goods are transported in containers, due to their versatile and standardized nature. Here’s a breakdown of common categories:

Manufactured goods:

Electronics: TVs, smartphones, computers, appliances, etc.

Clothing and textiles: Garments, footwear, fabrics, accessories.

Machinery and equipment: Industrial machinery, construction equipment, tools, medical devices.

Furniture: Tables, chairs, sofas, beds, cabinets.

Toys and games: Children’s toys, sporting goods, board games.

Raw materials and commodities:

Foodstuffs: Grains, fruits, vegetables, meat, dairy products, processed food.

Beverages: Bottled water, soft drinks, alcoholic beverages.

Chemicals: Plastics, fertilizers, paints, cleaning products.

Paper and wood products: Pulp, paper rolls, furniture components, lumber.

Metals and minerals: Steel, aluminum, copper, iron ore, coal.

Other goods:

Pharmaceuticals: Medicines, medical supplies, vaccines.

Dangerous goods: Flammables, explosives, hazardous chemicals (subject to strict regulations).

Personal belongings: Furniture, appliances, luggage, during international moves.

Live plants and animals: Requires specialized containers and permits.

It’s important to note that not all goods are suitable for container transport. Some examples include:

Oversized cargo: Heavy machinery, wind turbine blades, large vehicles, require specialized transport.

Perishable goods: Fresh fruits, vegetables, and certain medications might require temperature-controlled containers or faster transport via air.

Live animals: Require specific ventilation, feeding, and waste management systems within containers.

Overall, the list of goods transported in containers is extensive and constantly evolving. Containerization’s efficiency and flexibility make it an essential tool for global trade and supply chains, facilitating the movement of diverse goods across continents.

What is container transport security?

Container transport security refers to the various measures and practices implemented to safeguard cargo and prevent unauthorized access, theft, damage, or other security threats throughout the container’s journey. It’s crucial for ensuring the integrity, safety, and efficiency of global trade, encompassing various aspects:

Physical security:

Seals: Tamper-evident seals are applied to containers at origin and verified at each stage of transport, ensuring unauthorized opening is detected.

Locks: Containers are secured with robust locks to prevent physical access.

Monitoring and surveillance: Ports, terminals, and transport routes are monitored with security cameras, personnel, and technology to deter and detect suspicious activity.

Access control:

Authorized personnel: Only authorized individuals with proper identification and access control permissions can handle containers at each stage.

Cargo screening: X-ray scanners and other technologies are used to screen containers for suspicious contents or hidden compartments.

Electronic tracking: Containers are equipped with GPS trackers or RFID tags to monitor their location and movement in real-time.

Information security:

Secure communication: Secure communication channels are used to exchange sensitive information about cargo and shipments.

Data protection: Cargo manifests, customs documentation, and other sensitive data are protected with robust cybersecurity measures.

Risk management: Companies implement risk management frameworks to identify and mitigate potential security vulnerabilities throughout the supply chain.

International regulations:

International Maritime Organization (IMO) and other regulatory bodies: Establish international standards and guidelines for container transport security, which countries and companies must adhere to.

Customs inspections: Containers are subject to customs inspections at various points to ensure compliance with regulations and identify potential contraband.

Challenges and considerations:

Complexity of supply chains: Containers often travel through multiple countries and jurisdictions, making it challenging to maintain consistent security measures.

Emerging threats: New technologies and criminal methods necessitate continuous adaptation and improvement of security practices.

Cost-effectiveness: Balancing security needs with cost considerations is crucial for businesses involved in container transport.

Overall, container transport security is a multi-layered and evolving field aiming to ensure the safe and secure movement of goods across borders. By implementing robust physical, access control, information security measures, and adhering to regulations, stakeholders can contribute to a more secure and efficient global trade environment.

What are the three main types of containers?

There isn’t a universally agreed upon classification of container types, as different sources might focus on various aspects like size, function, or special features. However, considering several perspectives, here are three potential interpretations of “three main types of containers”:

1. By size:

Dry cargo containers: These are the most common type, used for various general cargo and come in standard sizes like 20ft and 40ft.

High-cube containers: These are slightly taller than standard dry containers, offering more cubic capacity for lighter cargo.

Tank containers: Designed for transporting liquids, typically in sizes similar to 20ft dry containers.

2. By function:

Dry cargo containers: As mentioned above, the most common for general cargo.

Refrigerated containers (reefers): Equipped with refrigeration units to maintain specific temperatures for perishable goods.

Open-top containers: Have an open roof for loading oversized or top-loading cargo. Other variations include open-side and flatbed containers for specific needs.

3. By special features:

Standard dry cargo containers: The basic, general-purpose option.

Dangerous goods containers: Reinforced and meet specific regulations for transporting hazardous materials.

Tank containers: Specialized for liquids, with various linings and pressure ratings depending on the cargo.

Remember that these are just a few possible interpretations, and the “main” types can vary based on your specific focus or industry. For a more detailed understanding, it’s helpful to explore resources that categorize containers based on your particular needs and interests.

What is the mileage of container truck?

The mileage can vary greatly depending on several factors:

Truck type and size:

Smaller trucks: Smaller container trucks like 20ft options generally have better fuel efficiency and higher mileage compared to larger 40ft trailers.

Specialized trucks: Refrigerated trucks or flatbed trucks might have lower mileage due to their heavier weight and additional equipment.

Engine and drivetrain:

Modern engines: Newer trucks with advanced engines and optimized drivetrains typically offer better fuel efficiency and higher mileage.

Older models: Older trucks with less efficient engines might have significantly lower mileage.

Operating conditions:

Terrain: Frequent driving on hilly or mountainous roads significantly impacts fuel efficiency and reduces mileage.

Road quality: Rough and uneven roads can increase fuel consumption and wear on the engine, negatively impacting mileage.

Weather: Extreme weather conditions like excessive heat or cold can affect engine performance and mileage.

Driving habits:

Smooth driving: Smooth and responsible driving practices like avoiding harsh acceleration and braking conserve fuel and improve mileage.

Overloading: Exceeding the truck’s weight capacity puts stress on the engine and significantly reduces mileage.

Maintenance:

Regular maintenance: Following proper maintenance schedules and using high-quality parts ensure optimal engine performance and fuel efficiency, contributing to better mileage.

Neglecting maintenance: Skipping maintenance or using low-quality parts can lead to engine issues and decreased mileage.

Considering these factors, here’s a general range of fuel efficiency (in kilometers per liter) for different container trucks:

Small container trucks (20ft): 6-8 km/liter

Medium container trucks (32ft): 5-7 km/liter

Large container trucks (40ft): 4-6 km/liter

Remember, these are just estimates, and the actual mileage of your container truck can differ significantly based on the factors mentioned above.

For a more accurate estimate of your specific truck’s mileage, it’s crucial to consider its individual characteristics, operating conditions, and maintenance practices. Consulting the truck’s manufacturer manual or talking to experienced drivers and fleet managers can also provide valuable insights.

Container transport business profitable?

Whether the container transport business is profitable depends on several factors and can be a complex question to answer definitively. Here’s a breakdown of some key points to consider:

Profitability factors:

Market conditions: The overall demand for container transport fluctuates based on global trade activity and economic conditions. During periods of high demand, profit margins can be better, while recessions can lead to lower profits or even losses.

Operational efficiency: Efficient operations are crucial for profitability. This involves factors like optimizing routes, minimizing fuel consumption, controlling maintenance costs, and utilizing resources effectively.

Competition: The container transport industry is highly competitive, with numerous players vying for business. Negotiating competitive rates and standing out with value-added services can be crucial.

Truck ownership vs. brokerage: Owning and maintaining a fleet of trucks comes with significant upfront costs and ongoing expenses. Operating as a broker, connecting shippers with carriers, can be less capital-intensive but involves different profit margins and risks.

Route selection: Short-haul routes might offer quicker turnaround times but lower profits per trip, while long-distance routes can offer higher profits but involve longer journey times and potential delays.

Customer base and pricing strategies: Building a loyal customer base with long-term contracts can provide stability and higher profits, while relying on spot market rates can be more volatile but potentially offer higher margins on individual trips.

Overall, the container transport business can be profitable, but it requires careful planning, efficient operations, and a good understanding of market dynamics. It’s not a guaranteed path to riches, and success depends on navigating various challenges and making strategic decisions.

Here are some additional points to consider:

Profitability can vary significantly by region and market segment. For example, specialized container transport, like refrigerated trucks, might have different profit margins than standard dry container haulage.

The industry is constantly evolving, with technological advancements and changing regulations impacting operations and profitability. Adaptability and innovation are key for long-term success.

Carefully evaluating the risks and potential rewards is crucial before entering the container transport business. Consulting with experienced professionals and conducting thorough market research can be helpful.

Remember, there’s no one-size-fits-all answer to whether the container transport business is profitable. By carefully considering the factors mentioned above and conducting your own research, you can make an informed decision about whether it’s the right path for you.

How can I start my own container truck transportation successful business?

Starting your own container truck transportation business can be a rewarding and challenging venture. Here are some key steps to consider for success:

Planning and Research:

Market Research: Conduct thorough research on the container transport industry in your region. Analyze market trends, demand, competition, and potential profit margins.

Business Plan: Develop a comprehensive business plan outlining your target market, services offered, pricing strategy, operational procedures, financial projections, and marketing approach.

Regulations and Licensing: Research and comply with all necessary regulations and licensing requirements for operating a container truck business in your region. This includes obtaining permits, insurance, and safety certifications.

Financial Planning: Determine your startup costs, including truck purchase/lease, maintenance, fuel, insurance, personnel, and marketing expenses. Secure funding through personal investment, loans, or other means.

Operations and Logistics:

Choose Your Niche: Decide whether you’ll focus on specific routes, cargo types, or specialized trucks (e.g., refrigerated transport).

Develop Partnerships: Build relationships with shippers, freight forwarders, and other industry players to secure consistent cargo contracts and expand your network.

Operational Efficiency: Optimize your routes, manage fuel consumption effectively, and develop efficient maintenance practices to minimize costs.

Technology Adoption: Utilize technology solutions for fleet management, tracking, routing optimization, and communication to streamline operations and improve efficiency.

Building Your Brand and Customer Base:

Competitive Pricing: Offer competitive rates while ensuring profitability. Consider value-added services to differentiate yourself from competitors.

Marketing and Customer Service: Develop a marketing strategy to reach your target audience and highlight your unique selling points. Provide excellent customer service to build trust and loyalty.

Building a Team: Depending on your needs, consider hiring experienced drivers, dispatchers, and other personnel to manage your operations effectively.

Compliance and Safety: Adhere to all safety regulations and industry best practices to ensure the safety of your drivers, cargo, and the public.

Additional Tips:

Seek Mentorship: Connect with experienced individuals in the container transport industry to gain valuable insights and guidance.

Join Industry Associations: Participating in industry associations can provide networking opportunities, resources, and support.

Stay Updated: Continuously stay informed about market trends, regulatory changes, and new technologies to adapt and remain competitive.

Remember, success takes time, effort, and dedication. By carefully planning, executing your strategy efficiently, and providing excellent service, you can increase your chances of building a successful container truck transportation business.

How to transport a shipping container ?

The way you transport a shipping container depends on numerous factors, including:

1. Distance:

Short distances: For short distances within a city or region, you can use a flatbed truck or a trailer with a crane.

Long distances: For long distances, the most common option is a container ship. You can also use rail freight for inland transportation.

2. Size and weight:

Standard containers: Standard 20ft and 40ft containers can be transported on most trucks and ships.

Oversized containers: Oversized or heavier containers might require specialized trucks with permits and specific routes.

3. Purpose:

Moving personal belongings: You can use shipping containers for international moves by loading them with your belongings and transporting them by ship.

Business purposes: Businesses use containers for various purposes like cargo transport, temporary storage, or even building structures.

Here are the general steps involved in transporting a shipping container:

1. Choose a transportation method:

Research various options and compare costs, timelines, and suitability for your specific needs.

Consider factors like distance, size, weight, and budget.

2. Hire a transportation company:

Find a reputable company with experience in transporting containers.

Get quotes from multiple companies and compare their services and prices.

3. Prepare the container:

Ensure the container is in good condition and secure your belongings properly.

Check if any special packing or securing is needed based on the cargo.

4. Obtain permits and documentation:

Depending on the route and purpose, you might need permits for oversized cargo or international shipping.

Prepare necessary customs documentation and insurance for your belongings.

5. Track and monitor the transportation:

The transportation company should provide updates and tracking information.

Ensure the container arrives at its destination safely and on time.

Additional resources:

Container transport companies: Search online for companies specializing in container transport in your area.

Logistics and freight forwarding companies: These companies can help you with all aspects of transporting your container, including choosing the right method, obtaining permits, and handling customs clearance.

Industry associations: Associations like the American Trucking Associations (ATA) or the International Container Terminal and Associated Operators (ICTAO) provide information and resources about the container transport industry.

Remember, transporting a shipping container requires careful planning and attention to detail. By choosing the right method, hiring a reputable company, and following the necessary steps, you can ensure your container arrives at its destination safely and efficiently.

How do containers help to facilitate intermodal transportation ?

Containers play a crucial role in facilitating intermodal transportation by offering several key advantages:

Standardization:

Uniform size and specifications: Containers come in specific standard sizes (like 20ft and 40ft) with international regulations (ISO) ensuring compatibility across different transport modes (ships, trucks, trains). This allows seamless transfer of the container itself without unloading the cargo, saving time, labor, and costs.

Easy handling and stacking: Standardized dimensions enable efficient loading, unloading, and stacking of containers on ships, trucks, and trains, maximizing space utilization and transport efficiency.

Intermodality:

Seamless transfer: The same container can be seamlessly switched between ships, trucks, and trains without handling individual cargo items, simplifying logistics and reducing potential damage or loss.

Flexibility: Intermodal transportation allows businesses to choose the most efficient and cost-effective combination of transport modes based on their specific needs and route. For example, combining ship transport for long distances with trucks for inland delivery.

Efficiency:

Reduced handling: Minimizing cargo handling through containerization decreases associated costs, labor, and potential damage, leading to faster turnaround times and lower overall transport costs.

Faster loading/unloading: Standardized containers enable efficient loading and unloading on various transport modes using cranes and specialized equipment, further streamlining the process.

Security and protection:

Weatherproof enclosure: Containers offer secure and weatherproof protection for cargo throughout the journey, reducing exposure to elements and potential damage.

Tamper-evident seals: Seals applied at origin and verified at each stage of transport help deter unauthorized access and ensure cargo integrity.

Overall, containerization acts as a critical enabler for intermodal transportation, contributing to:

Reduced costs and increased efficiency: By minimizing handling, maximizing space utilization, and offering flexibility in transport modes.

Faster delivery times: Through seamless intermodal transfers and efficient loading/unloading.

Enhanced security and cargo protection: With standardized containers and security measures.

Global trade facilitation: By enabling efficient and cost-effective movement of goods across continents and modes of transport.

In conclusion, containers are not just boxes but essential tools for modern intermodal transportation, ensuring the smooth, efficient, and secure movement of goods across the globe.

How much to transport shipping container ?

it’s impossible to give you a single, definitive answer to how much it costs to transport a shipping container, as the price depends on a multitude of factors. Here are some of the key variables that significantly affect the cost:

1. Distance:

Short distances: Moving a container within a city or region will be much cheaper than shipping it across continents.

Long distances: International shipping via container ships is generally the most expensive option, but can be cost-effective for large volumes over long distances.

2. Size and weight:

Standard containers: Standard 20ft and 40ft containers are the most affordable to transport.

Oversized or heavy containers: These require specialized equipment and permits, significantly increasing the cost.

3. Transportation mode:

Ship: The most common option for long distances, but prices fluctuate based on fuel costs, route, and container availability.

Truck: More flexible for inland locations but generally more expensive per kilometer compared to ships.

Train: Often cheaper than trucks for long distances but may have limited network reach and slower transit times.

Intermodal: Combining different modes (e.g., ship-to-truck) can optimize costs and speed but involves coordination complexity.

4. Additional factors:

Origin and destination: Costs can vary based on specific ports, terminals, and inland transportation infrastructure.

Urgency: Expedited shipping is more expensive than standard options.

Customs clearance: For international shipments, customs fees and inspections can add to the cost.

Insurance: Protecting your cargo with insurance adds to the overall cost.

Instead of a single price, here’s what you can do to estimate the cost of transporting your container:

Specify your needs: Clearly define the container size, weight, origin, destination, and desired timeframe.

Get quotes: Contact multiple shipping companies and freight forwarders, outlining your specific requirements. They can provide personalized estimates based on current market rates and their services.

Compare and choose: Carefully compare quotes from different providers, considering factors like price, reputation, reliability, and additional services offered.

Remember, relying solely on generic online estimates might not be accurate. By clearly defining your needs and getting personalized quotes, you’ll be in a better position to make informed decisions and find the most cost-effective solution for transporting your shipping container.

Why are aluminium containers used to transport nitric acid ?

Aluminium containers are used to transport concentrated nitric acid because of a fascinating property: aluminium forms a protective oxide layer when it comes in contact with nitric acid. This layer, primarily aluminium oxide (Al2O3), acts as a barrier, preventing further reaction between the metal and the acid. Here’s a breakdown of the key reasons:

Passivity:

Aluminium reacts with nitric acid to form a thin, tightly adherent layer of aluminium oxide. This layer is highly resistant to further oxidation, effectively passivating the aluminium surface and preventing further dissolution.

Nitric acid is an oxidizing agent: It readily reacts with metals, causing them to corrode and dissolve. However, the aluminium oxide layer formed is insoluble in nitric acid, essentially protecting the underlying metal from further attack.

Safety and cost-effectiveness:

Compared to other materials like steel or iron, aluminium is lighter and less expensive. This makes it a more cost-effective choice for transporting nitric acid, especially for larger volumes.

Aluminium’s passivity eliminates the need for expensive corrosion-resistant linings or coatings inside the container, further reducing costs and simplifying maintenance.

Limitations:

It’s important to note that this passivity only applies to concentrated nitric acid. Dilute nitric acid can still react with aluminium and cause corrosion.

Contamination with other chemicals or impurities can compromise the oxide layer’s integrity, leading to potential corrosion and safety concerns.

Additional factors:

The thickness and stability of the oxide layer depend on various factors like temperature and concentration of the acid. It’s crucial to ensure proper handling and storage conditions to maintain the layer’s effectiveness.

Regulations and safety guidelines must be strictly followed when transporting nitric acid, regardless of the container material. This includes proper labeling, spill containment measures, and emergency procedures.

In conclusion, aluminium containers are suitable for transporting concentrated nitric acid due to the formation of a protective oxide layer that prevents further reaction and corrosion. However, it’s critical to understand the limitations and adhere to safety regulations for safe and responsible transportation.