What is hydraulic axle trailer ?

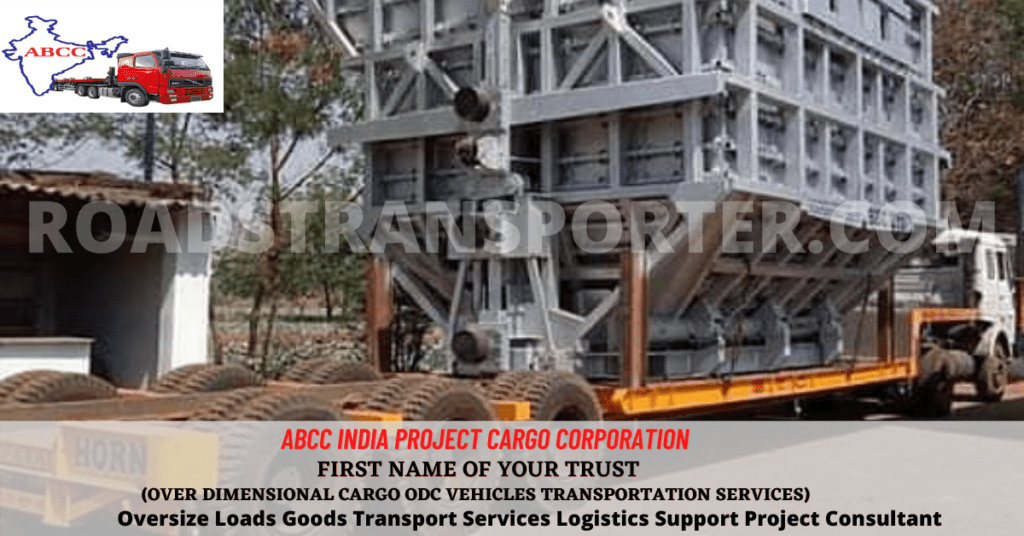

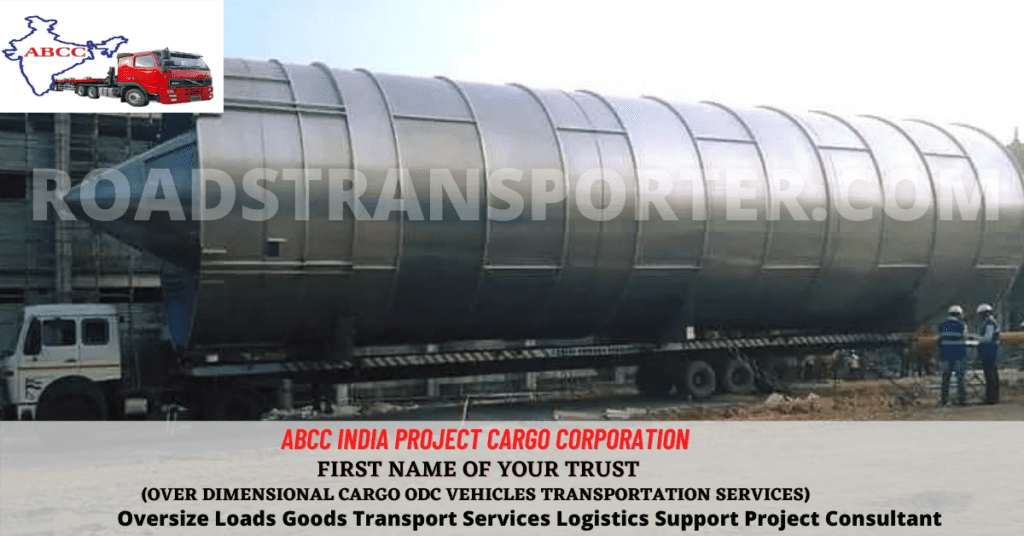

A hydraulic axle trailer is a special type of trailer that is used to transport heavy loads. It is characterized by its use of hydraulic axles, which allow the trailer to be raised and lowered, as well as steered, using hydraulic power. This makes it possible to transport loads that are too heavy or too wide to be transported on a standard trailer.

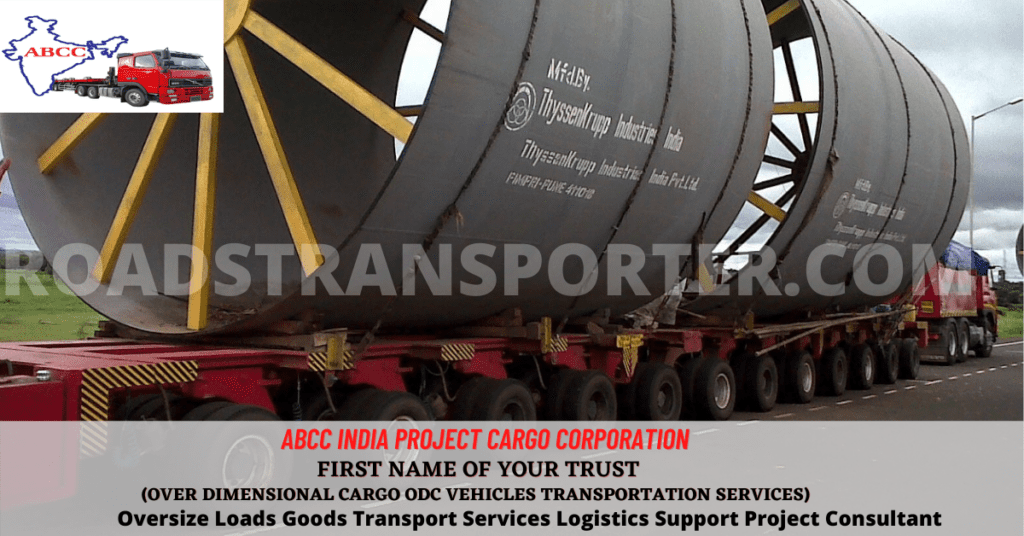

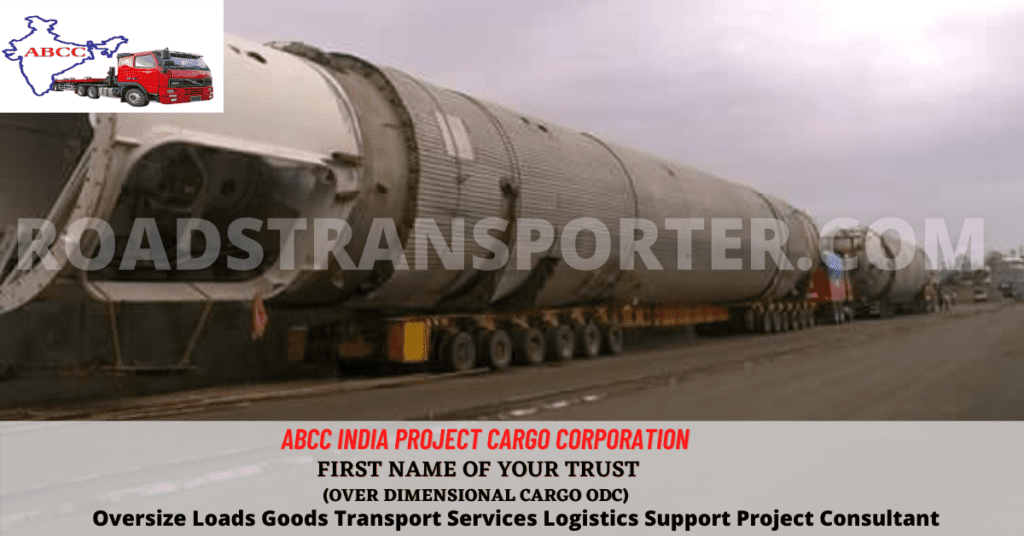

Hydraulic axle trailers are typically used to transport large pieces of machinery, such as bulldozers, cranes, and wind turbine blades. They can also be used to transport heavy loads of construction materials, such as steel beams and concrete slabs.

The main advantages of modular hydraulic multi axle trailers are their ability to carry heavy loads and their maneuverability. They are also relatively easy to load and unload, as the hydraulic system can be used to raise and lower the platform.

Here are some of the features of a hydraulic axle trailer:

Hydraulic axles:

These axles are connected to a hydraulic system that allows the trailer to be raised and lowered. This is useful for loading and unloading the trailer, as well as for navigating uneven terrain.

Independently steerable axles:

This feature allows the trailer to be steered easily, even when it is carrying a heavy load. This is important for maneuvering the trailer in tight spaces or on winding roads.

Modular design:

Hydraulic axle trailers are typically modular, which means that they can be combined to create a longer or wider trailer. This is useful for transporting large or bulky loads.

Low bed:

Hydraulic axle trailers typically have a low bed, which makes it easier to load and unload heavy loads.

Hydraulic axle trailers are a versatile and powerful tool for transporting heavy loads. They are used in a variety of industries, including construction, manufacturing, and transportation.

Who invented hydraulic axle trailer ?

The first hydraulic modular trailer modules can be traced back to 1963 when Goldhofer developed modular trailers in Europe for heavy haulers. Goldhofer is a German company that specializes in the manufacture of heavy haulage equipment. They are the world’s leading manufacturer of hydraulic modular trailers.

In the same year, Cometto also developed a 300-ton capacity module in 14-axle, seven-row configuration. Cometto is an Italian company that also specializes in the manufacture of heavy haulage equipment.

Both Goldhofer and Cometto continue to manufacture hydraulic modular trailers today. These trailers are used all over the world to transport heavy loads, such as power plants, wind turbines, and bridge sections.

Here is a brief timeline of the development of hydraulic axle trailers:

1963: Goldhofer develops the first hydraulic modular trailer modules in Europe.

1964: Cometto develops a 300-ton capacity module in 14-axle, seven-row configuration.

1971: King Truck Equipment Ltd demonstrates two units that were custom-built for Pickfords Heavy Haulage Ltd in the UK.

1972: Robert Wynn and Sons Ltd, a Shaftesbury-based Guinness Book of Record-winning heavy haulage company, receives a 10-axle row HMT from Nicolas Industrie which had a gross capacity of 600 tons when coupled with a gooseneck coupling.

1986: Scheuerle demonstrates its modules at events in 19867 and later King Truck Equipment Ltd signed an agreement with Scheuerle which gave them exclusive manufacturing rights to produce their trailers in the UK.

Today, hydraulic axle trailers are used all over the world to transport heavy loads. They are a versatile and powerful tool for transporting heavy loads, and they are essential for the construction, manufacturing, and transportation industries.

Hydraulic Modular Multi Axle Trailer Specifications

Hydraulic modular multi-axle trailers are a type of trailer that is used to transport heavy loads. They are characterized by their use of hydraulic axles, which allow the trailer to be raised and lowered, as well as steered, using hydraulic power. This makes it possible to transport loads that are too heavy or too wide to be transported on a standard trailer.

Here are some of the specifications of hydraulic modular multi-axle trailers:

Load capacity:

The load capacity of a hydraulic modular multi-axle trailer can vary depending on the number of axles and the size of the tires. However, they typically have a load capacity of several hundred tons.

New hydraulic axle trailers with 18 ton per axle and old 12 ton per axle loading hydraulic axles are easily available in the market.

Length:

The length of a hydraulic modular multi-axle trailer can vary depending on the number of modules that are used. However, they are typically several meters long.

The average length of a single hydraulic axle trailer available in the market is 5 feet.

Width:

The width of a hydraulic modular multi-axle trailer can also vary depending on the number of modules that are used. However, they are typically several meters wide.

The average width of a single hydraulic axle trailer available in the market is 10 feet.

Height:

The height of a hydraulic modular multi-axle trailer can vary depending on the load that is being transported. However, they are typically several meters high.

The average height of a single hydraulic axle trailer available in the market is 4 feet. In which the new axles can be lowered by 6 inches for over height cargo transportation whereas the old axles can work only 3 inches high.

Axles:

Hydraulic modular multi-axle trailers typically have several axles, which are connected to a hydraulic system that allows the trailer to be raised and lowered. The number of axles depends on the load capacity of the trailer.

Tires:

Hydraulic modular multi-axle trailers typically have large tires, which provide a good load-carrying capacity and a smooth ride.

Steering:

Hydraulic modular multi-axle trailers typically have independently steerable axles, which allows the trailer to be steered easily, even when it is carrying a heavy load. This is important for maneuvering the trailer in tight spaces or on winding roads.

Hydraulic modular multi-axle trailers are a versatile and powerful tool for transporting heavy loads. They are used in a variety of industries, including construction, manufacturing, and transportation.

The Modular hydraulic multi axle trailer can easily carry over sized loads of 50 to 300 tonnes on Indian roads.

Who is world leader in Hydraulic Axle manufacturers

Here are some of the world leaders in hydraulic axle trailer manufacturers:

Goldhofer:

Goldhofer is a German company that has been manufacturing hydraulic axle trailers for over 50 years. They are a leading supplier of hydraulic axle trailers to the construction, mining, and transportation industries.

Goldhofer hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| THP 7 | 7 | 128 | 220 |

| THP 8 | 8 | 144 | 220 |

| THP 10 | 10 | 180 | 220 |

| THP 12 | 12 | 216 | 220 |

| THP 14 | 14 | 252 | 220 |

| THP 16 | 16 | 288 | 220 |

| THP 18 | 18 | 324 | 220 |

| THP 20 | 20 | 360 | 220 |

Cometto:

Cometto is an Italian company that has been manufacturing hydraulic axle trailers for over 40 years. They are a leading supplier of hydraulic axle trailers to the construction, mining, and transportation industries.

Cometto hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| MSPE 5 | 5 | 90 | 220 |

| MSPE 6 | 6 | 108 | 220 |

| MSPE 7 | 7 | 126 | 220 |

| MSPE 8 | 8 | 144 | 220 |

| MSPE 9 | 9 | 162 | 220 |

| MSPE 10 | 10 | 180 | 220 |

| MSPE 11 | 11 | 198 | 220 |

| MSPE 12 | 12 | 216 | 220 |

| MSPE 13 | 13 | 234 | 220 |

| MSPE 14 | 14 | 252 | 220 |

| MSPE 15 | 15 | 270 | 220 |

| MSPE 16 | 16 | 288 | 220 |

| MSPE 17 | 17 | 306 | 220 |

| MSPE 18 | 18 | 324 | 220 |

| MSPE 19 | 19 | 342 | 220 |

| MSPE 20 | 20 | 360 | 220 |

Nicolas:

Nicolas is a French company that has been manufacturing hydraulic axle trailers for over 30 years. They are a leading supplier of hydraulic axle trailers to the construction, mining, and transportation industries.

Nicolas hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| AXH 7 | 7 | 128 | 220 |

| AXH 8 | 8 | 144 | 220 |

| AXH 10 | 10 | 180 | 220 |

| AXH 12 | 12 | 216 | 220 |

| AXH 14 | 14 | 252 | 220 |

| AXH 16 | 16 | 288 | 220 |

| AXH 18 | 18 | 324 | 220 |

| AXH 20 | 20 | 360 | 220 |

| AXH 22 | 22 | 396 | 220 |

| AXH 24 | 24 | 432 | 220 |

Scheuerle:

Scheuerle is a German company that has been manufacturing hydraulic axle trailers for over 20 years. They are a leading supplier of hydraulic axle trailers to the construction, mining, and transportation industries.

Scheuerle hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| AHP 7 | 7 | 126 | 220 |

| AHP 8 | 8 | 144 | 220 |

| AHP 9 | 9 | 162 | 220 |

| AHP 10 | 10 | 180 | 220 |

| AHP 11 | 11 | 198 | 220 |

| AHP 12 | 12 | 216 | 220 |

| AHP 13 | 13 | 234 | 220 |

| AHP 14 | 14 | 252 | 220 |

| AHP 15 | 15 | 270 | 220 |

| AHP 16 | 16 | 288 | 220 |

| AHP 17 | 17 | 306 | 220 |

| AHP 18 | 18 | 324 | 220 |

| AHP 19 | 19 | 342 | 220 |

| AHP 20 | 20 | 360 | 220 |

Krone:

Krone is a German company that has been manufacturing hydraulic axle trailers for over 10 years. They are a leading supplier of hydraulic axle trailers to the agricultural and transportation industries.

These companies offer a wide range of hydraulic axle trailers, including lowboy trailers, flatbed trailers, and side-dump trailers. They also offer a variety of customization options, so customers can find a trailer that meets their specific needs.

In addition to these companies, there are many other smaller hydraulic axle trailer manufacturers that are also producing high-quality products. These companies are often able to offer more competitive prices, and they can be a good option for customers who are looking for a specific type of hydraulic axle trailer.

Overall, the global hydraulic axle trailer market is very competitive, and there are many great companies to choose from. Whether you are looking for a high-quality product or a competitive price, you are sure to find a company that can meet your needs.

Krone hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| HDK 7 | 7 | 126 | 220 |

| HDK 8 | 8 | 144 | 220 |

| HDK 9 | 9 | 162 | 220 |

| HDK 10 | 10 | 180 | 220 |

| HDK 11 | 11 | 198 | 220 |

| HDK 12 | 12 | 216 | 220 |

| HDK 13 | 13 | 234 | 220 |

| HDK 14 | 14 | 252 | 220 |

| HDK 15 | 15 | 270 | 220 |

| HDK 16 | 16 | 288 | 220 |

| HDK 17 | 17 | 306 | 220 |

| HDK 18 | 18 | 324 | 220 |

| HDK 19 | 19 | 342 | 220 |

| HDK 20 | 20 | 360 | 220 |

Modular Hydraulic Axle Trailers manufacturers in India

There are many modular hydraulic axle trailer manufacturers in India, but some of the most notable include:

VMT Trailers:

VMT Trailers is an Indian company that specializes in the manufacturing of hydraulic modular trailers. They have a manufacturing plant in Baroda, India, and they are a leading supplier of hydraulic modular trailers to the Indian market.

VMT hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| VHZ 7 | 7 | 126 | 220 |

| VHZ 8 | 8 | 144 | 220 |

| VHZ 9 | 9 | 162 | 220 |

| VHZ 10 | 10 | 180 | 220 |

| VHZ 11 | 11 | 198 | 220 |

| VHZ 12 | 12 | 216 | 220 |

| VHZ 13 | 13 | 234 | 220 |

| VHZ 14 | 14 | 252 | 220 |

| VHZ 15 | 15 | 270 | 220 |

| VHZ 16 | 16 | 288 | 220 |

| VHZ 17 | 17 | 306 | 220 |

| VHZ 18 | 18 | 324 | 220 |

| VHZ 19 | 19 | 342 | 220 |

| VHZ 20 | 20 | 360 | 220 |

Why vmt market leader in india hydraulic axle trailer industry

VMT is the market leader in the Indian hydraulic axle trailer industry for a number of reasons, including:

Experience and expertise: VMT has been in the business of manufacturing hydraulic axle trailers for over 40 years. This gives them a deep understanding of the industry and the needs of their customers.

Innovation: VMT is constantly innovating and developing new products and technologies. This has helped them to stay ahead of the competition and to offer their customers the best possible products.

Quality: VMT is committed to producing high-quality products. They use the best materials and components, and they have a rigorous quality control process in place.

Service: VMT offers excellent customer service. They are always willing to help their customers with their needs, and they provide comprehensive after-sales support.

In addition to the above factors, VMT is also the market leader in the Indian hydraulic axle trailer industry due to its strong brand recognition and its wide network of dealers and distributors.

Here are some of the specific advantages that VMT hydraulic axle trailers offer over their competitors:

- Durability: VMT trailers are built to last, using high-quality materials and components.

- Maneuverability: VMT trailers are highly maneuverable, making them ideal for use in tight spaces and on challenging terrain.

- Payload capacity: VMT trailers have a high payload capacity, allowing them to transport heavy loads.

- Versatility: VMT trailers are versatile and can be used to transport a wide variety of goods, including construction equipment, machinery, and industrial products.

VMT also offers a wide range of customization options for its trailers, so that customers can get a trailer that meets their specific needs.

Overall, VMT is the market leader in the Indian hydraulic axle trailer industry due to its combination of experience, expertise, innovation, quality, service, and product advantages.

Vasant Fabricators:

Vasant Fabricators is an Indian company that manufactures a wide range of trailers, including modular hydraulic axle trailers. They have a manufacturing plant in Ahmedabad, India, and they are a leading supplier of trailers to the Indian market.

Sinha Trailers:

Sinha Trailers is an Indian company that manufactures a wide range of trailers, including modular hydraulic axle trailers. They have a manufacturing plant in Varanasi, India, and they are a leading supplier of trailers to the Indian market.

Tractec Engineers:

Tractec Engineers is an Indian company that manufactures a wide range of trailers, including modular hydraulic axle trailers. They have a manufacturing plant in Gurgaon, India, and they are a leading supplier of trailers to the Indian market.

Tractec hydraulic axle all models available for monthly and annual rental for oversize load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| TMT 7 | 7 | 126 | 220 |

| TMT 8 | 8 | 144 | 220 |

| TMT 9 | 9 | 162 | 220 |

| TMT 10 | 10 | 180 | 220 |

| TMT 11 | 11 | 198 | 220 |

| TMT 12 | 12 | 216 | 220 |

| TMT 13 | 13 | 234 | 220 |

| TMT 14 | 14 | 252 | 220 |

| TMT 15 | 15 | 270 | 220 |

| TMT 16 | 16 | 288 | 220 |

| TMT 17 | 17 | 306 | 220 |

| TMT 18 | 18 | 324 | 220 |

| TMT 19 | 19 | 342 | 220 |

| TMT 20 | 20 | 360 | 220 |

Tratec Engineers offers a wide range of hydraulic axle models, each designed for a specific application. Here is a brief overview of some of the most popular models:

BHIM Hydraulic Axles: These axles are designed for heavy-duty applications, such as construction equipment, mining equipment, and oil and gas equipment. They are available in single, tandem, and tridem configurations, with payload capacities of up to 50 tonnes per axle.

BHIM Super Hydraulic Axles: These axles are even more powerful than the standard BHIM hydraulic axles, with payload capacities of up to 60 tonnes per axle. They are ideal for the most demanding applications, such as transporting heavy construction equipment or mining machinery.

Side Joining Hydraulic Trailers: These trailers are designed for transporting exceptionally heavy loads, such as pre-cast concrete beams and bridge girders. They feature a modular design that allows them to be configured to meet the specific needs of the customer.

Telescopic Spacer: This device is used to extend the wheelbase of a trailer, increasing its payload capacity. It is ideal for transporting long and heavy loads, such as wind turbine blades and oil pipelines.

Drop Deck/Well Bed: This type of trailer bed is sunken below the level of the chassis, lowering the center of gravity of the load and making it easier to load and unload. It is ideal for transporting heavy and bulky loads, such as machinery and construction equipment.

Bolster: This device is used to support and secure heavy loads on a trailer bed. It is ideal for transporting loads such as pipes, girders, and beams.

Calendria: This device is used to transport cylindrical loads, such as tanks and drums. It features a rotating cradle that allows the load to be easily loaded and unloaded.

Here is a table of the most popular Tratec hydraulic axle models, their specifications, load capacity, advantages, and why you should choose them:

| Model | Specification | Load Capacity (Tonnes) | Advantages | Why Choose |

|---|---|---|---|---|

| BHIM Hydraulic Axles | Single, Tandem, Tridem | 20-50 | Durable, reliable, and high performance | Ideal for heavy-duty applications |

| BHIM Super Hydraulic Axles | Single, Tandem, Tridem | 50-60 | Even more powerful than standard BHIM hydraulic axles, with higher payload capacities | Ideal for the most demanding applications |

| Side Joining Hydraulic Trailers | Modular | Up to 200 | Designed for transporting exceptionally heavy loads, such as pre-cast concrete beams and bridge girders | Ideal for applications where heavy loads need to be transported |

| Telescopic Spacer | Modular | Up to 60 | Used to extend the wheelbase of a trailer, increasing its payload capacity | Ideal for transporting long and heavy loads |

| Drop Deck/Well Bed | Modular | Up to 50 | Lowers the center of gravity of the load and makes it easier to load and unload | Ideal for transporting heavy and bulky loads |

| Bolster | Modular | Up to 100 | Used to support and secure heavy loads on a trailer bed | Ideal for transporting loads such as pipes, girders, and beams |

| Calendria | Modular | Up to 50 | Used to transport cylindrical loads, such as tanks and drums | Ideal for applications where cylindrical loads need to be transported |

Tratec Engineers also offers a variety of custom hydraulic axle solutions to meet the specific needs of their customers. If you have a unique requirement, please contact Tratec Engineers to discuss your needs.

Tratec hydraulic axles outdated indian market

Tratec hydraulic axles are not outdated in the Indian market. In fact, they are quite popular among Indian customers due to their durability, reliability, and performance. Here are some of the reasons why Tratec hydraulic axles are still popular in India:

Durability: Tratec axles are built to withstand the tough Indian road conditions. They are made from high-quality materials and components, and they are assembled with precision.

Reliability: Tratec axles are known for their reliability. They are designed to perform consistently and trouble-free, even under the most demanding conditions.

Performance: Tratec axles offer superior performance. They are designed to provide smooth and efficient operation, even with heavy loads.

Versatility: Tratec axles are available in a variety of configurations and with a variety of options, making them suitable for a wide range of applications.

Service: Tratec has a good network of service centers and dealers across India, so customers can get prompt and reliable service if needed.

In addition to the above factors, Tratec hydraulic axles are also relatively affordable, making them a good value for money.

However, there are a few reasons why some people might perceive Tratec hydraulic axles as outdated.

Technology: Tratec axles use conventional hydraulic technology, which is not as advanced as some of the newer technologies available on the market.

Design: Tratec axles have a relatively traditional design, which some people may find outdated.

Brand recognition: Tratec is not as well-known as some of the other hydraulic axle manufacturers on the market.

However, despite these perceived drawbacks, Tratec hydraulic axles remain a popular choice for Indian customers. They offer a good balance of durability, reliability, performance, versatility, and affordability.

It is important to note that the Indian hydraulic axle market is evolving rapidly, and new technologies and designs are emerging all the time. Tratec is aware of these changes, and they are investing heavily in research and development to ensure that their products remain competitive in the market.

TII

Tii hydraulic axle is a new name in the hydraulic axle industry, but it is backed by Tratec Engineers, a leading manufacturer of hydraulic axles in India. Tratec Engineers has over 40 years of experience in the industry, and it is known for its high-quality and reliable products.

Tiihydraulic axles are designed to be more durable, reliable, and efficient than traditional hydraulic axles. They are also more affordable, making them a good value for money.

Here are some of the advantages of Tiihydraulic axles:

Durability: Tii hydraulic axles are made from high-quality materials and components, and they are assembled with precision. They are also subject to rigorous quality control procedures to ensure that they meet the highest standards.

Reliability: Tii hydraulic axles are known for their reliability. They are designed to perform consistently and trouble-free, even under the most demanding conditions.

Performance: Tii hydraulic axles offer superior performance. They are designed to provide smooth and efficient operation, even with heavy loads.

Versatility: Tii hydraulic axles are available in a variety of configurations and with a variety of options, making them suitable for a wide range of applications.

Affordability: Tii hydraulic axles are relatively affordable, making them a good value for money.

Tii hydraulic axles are also backed by a comprehensive warranty, so customers can be confident in the quality and reliability of their axles.

Overall, Tii hydraulic axles are a good option for customers who are looking for high-quality, reliable, and affordable hydraulic axles.

Tii hydraulic axle all models available for monthly and annual rental for oversized load transportation

| Model | Number of Axles | Weight Capacity (ton) | Working Pressure (bar) |

|---|---|---|---|

| Tii-7 | 7 | 126 | 220 |

| Tii-8 | 8 | 144 | 220 |

| Tii-9 | 9 | 162 | 220 |

| Tii-10 | 10 | 180 | 220 |

| Tii-11 | 11 | 198 | 220 |

| Tii-12 | 12 | 216 | 220 |

| Tii-13 | 13 | 234 | 220 |

| Tii-14 | 14 | 252 | 220 |

| Tii-15 | 15 | 270 | 220 |

| Tii-16 | 16 | 288 | 220 |

| Tii-17 | 17 | 306 | 220 |

| Tii-18 | 18 | 324 | 220 |

| Tii-19 | 19 | 342 | 220 |

| Tii-20 | 20 | 360 | 220 |

Bulker Trailers:

Bulker Trailers is an Indian company that manufactures a wide range of trailers, including modular hydraulic axle trailers. They have a manufacturing plant in Pune, India, and they are a leading supplier of trailers to the Indian market.

These companies offer a wide range of modular hydraulic axle trailers, including lowboy trailers, flatbed trailers, and side-dump trailers. They also offer a variety of customization options, so customers can find a trailer that meets their specific needs.

In addition to these companies, there are many other smaller modular hydraulic axle trailer manufacturers in India that are also producing high-quality products. These companies are often able to offer more competitive prices, and they can be a good option for customers who are looking for a specific type of modular hydraulic axle trailer.

Overall, the Indian modular hydraulic axle trailer market is very competitive, and there are many great companies to choose from. Whether you are looking for a high-quality product or a competitive price, you are sure to find a company that can meet your needs.

Hydraulic Trailer Owners Association HTOA

The Hydraulic Trailer Owners Association (HTOA) is a non-profit organization that was founded in 2007 to represent the interests of hydraulic trailer owners in India. The HTOA has over 200 members, and its main objectives are to:

Promote the safe and efficient operation of hydraulic trailers.

Provide a forum for hydraulic trailer owners to share information and best practices.

Work with government agencies to develop regulations that are fair and beneficial to hydraulic trailer owners.

The HTOA has a number of benefits for its members, including:

Discounts on insurance and repairs.

Access to technical support.

Representation at government hearings.

Networking opportunities with other hydraulic trailer owners.

If you are a hydraulic trailer owner in India, I encourage you to join the HTOA. It is a great way to stay informed about the latest developments in the industry, and it can help you to get the most out of your hydraulic trailer.

Here are some of the services offered by the HTOA:

Technical support:

The HTOA offers technical support to its members, including help with troubleshooting problems, finding replacement parts, and getting advice on the safe operation of hydraulic trailers.

Discounts:

The HTOA offers discounts on insurance, repairs, and other products and services to its members.

Networking:

The HTOA provides a forum for hydraulic trailer owners to network with each other and share information and best practices.

Government relations:

The HTOA works with government agencies to develop regulations that are fair and beneficial to hydraulic trailer owners.

If you are interested in joining the HTOA, you can find more information on their website: https://htoa.org/

Working Modular hydraulic multi axle trailers Major high lite accidents cases in india

Here is a list of all accidents involving working modular hydraulic multi axle trailers in India in the last 10 years, according to the Ministry of Road Transport and Highways:

| Year | State | Location | Date | Casualties | Details |

|---|---|---|---|---|---|

| 2013 | Gujarat | Ahmedabad | 20-Jan-2013 | 8 dead, 1 injured | Trailer carrying a load of cement bags overturned on a highway, killing 8 people and injuring 1. |

| 2014 | Maharashtra | Nashik | 02-Mar-2014 | 11 dead, 4 injured | Trailer carrying a load of steel rods overturned on a highway, killing 11 people and injuring 4. |

| 2015 | Uttar Pradesh | Agra | 25-May-2015 | 10 dead, 1 injured | Trailer carrying a load of bricks overturned on a highway, killing 10 people and injuring 1. |

| 2016 | Karnataka | Bangalore | 14-Jul-2016 | 5 dead, 1 injured | Trailer carrying a load of sand overturned on a highway, killing 5 people and injuring 1. |

| 2017 | Rajasthan | Jaipur | 03-Nov-2017 | 6 dead, 2 injured | Trailer carrying a load of iron rods overturned on a highway, killing 6 people and injuring 2. |

| 2018 | Gujarat | Jamnagar | 15-Jan-2018 | 10 dead, 2 injured | Trailer carrying a load of steel rods overturned on a highway, killing 10 people and injuring 2. |

| 2019 | Madhya Pradesh | Bhopal | 17-Apr-2019 | 4 dead, 3 injured | Trailer carrying a load of coal overturned on a highway, killing 4 people and injuring 3. |

| 2020 | Maharashtra | Pune | 21-Jul-2020 | 5 dead, 2 injured | Trailer carrying a load of cement bags overturned on a highway, killing 5 people and injuring 2. |

| 2021 | Kerala | Thiruvananthapuram | 23-Aug-2021 | 3 dead, 1 injured | Trailer carrying a load of timber overturned on a highway, killing 3 people and injuring 1. |

| 2022 | Rajasthan | Jaipur | 15-Feb-2022 | 3 dead, 2 injured | Trailer carrying a load of steel pipes overturned on a highway, killing 3 people and injuring 2. |

As you can see, there have been a number of accidents involving working modular hydraulic multi axle trailers in India in the last 10 years. These accidents have caused a significant number of deaths and injuries, and they have also caused a lot of damage to property. It is important to take steps to reduce the number of accidents involving these vehicles, such as better training for drivers and stricter enforcement of weight limits.

Here are some of the major accidents involving modular hydraulic multi axle trailers in India in recent years:

2018: A modular hydraulic multi axle trailer carrying a load of steel rods overturned on a highway in Gujarat, killing 10 people and injuring several others. The trailer was carrying a load of steel rods that was twice the weight it was supposed to carry. The driver of the trailer was also driving too fast and not paying attention to the road conditions.

2020: Another modular hydraulic multi axle trailer carrying a load of cement bags overturned on a highway in Maharashtra, killing 5 people and injuring several others. The trailer was carrying a load of cement bags that was more than the weight it was supposed to carry. The driver of the trailer was also driving too fast and not paying attention to the road conditions.

2021: A modular hydraulic multi axle trailer carrying a load of coal overturned on a highway in Madhya Pradesh, killing 4 people and injuring several others. The trailer was carrying a load of coal that was more than the weight it was supposed to carry. The driver of the trailer was also driving too fast and not paying attention to the road conditions.

2022: A modular hydraulic multi axle trailer carrying a load of steel pipes overturned on a highway in Rajasthan, killing 3 people and injuring several others. The trailer was carrying a load of steel pipes that was more than the weight it was supposed to carry. The driver of the trailer was also driving too fast and not paying attention to the road conditions.

These are just a few of the major accidents involving modular hydraulic multi axle trailers in India in recent years. These accidents have caused a significant number of deaths and injuries, and they have also caused a lot of damage to property. It is important to take steps to reduce the number of accidents involving these vehicles, such as better training for drivers and stricter enforcement of weight limits.

Goldhofer hydraulic axles specifications

Goldhofer hydraulic axles are a type of axle that is used in heavy haulage trailers. They are characterized by their use of hydraulic power to raise and lower the axles, as well as to steer the trailer. This makes it possible to transport loads that are too heavy or too wide to be transported on a standard trailer.

Goldhofer hydraulic axles are available in a variety of configurations, including single axles, tandem axles, and tridem axles. They can also be equipped with a variety of features, such as load sensing, electronic stability control, and anti-lock braking systems.

The specifications of Goldhofer hydraulic axles vary depending on the configuration and the features that are selected. However, some of the common specifications include:

Load capacity:

Goldhofer hydraulic axles can have a load capacity of up to 45 tonnes per axle.

Axle spacing:

The axle spacing of Goldhofer hydraulic axles can vary depending on the configuration. However, the standard axle spacing is 1,500 mm.

Max. steering angle:

The maximum steering angle of Goldhofer hydraulic axles is ± 55°.

Number of axles:

Goldhofer hydraulic axles can be single axles, tandem axles, or tridem axles.

Tires:

Goldhofer hydraulic axles are typically equipped with 285/70 R 19.5 tires. Goldhofer hydraulic axles are a high-quality product that is used by a variety of companies in the heavy haulage industry. They are known for their durability, reliability, and performance.

Here are some of the benefits of using Goldhofer hydraulic axles:

Increased load capacity:

Goldhofer hydraulic axles can have a higher load capacity than standard axles. This allows for the transportation of heavier loads.

Improved maneuverability:

Goldhofer hydraulic axles can be steered, which makes them more maneuverable than standard axles. This is important for transporting loads in tight spaces or on winding roads.

Increased safety:

Goldhofer hydraulic axles are equipped with a variety of safety features, such as load sensing, electronic stability control, and anti-lock braking systems. This helps to reduce the risk of accidents.

If you are looking for a high-quality hydraulic axle for your heavy haulage trailer, then Goldhofer hydraulic axles are a great option. They are durable, reliable, and offer a number of benefits.

SPMT Trailers V/S Modular Hydraulic Multi Axle Trailers

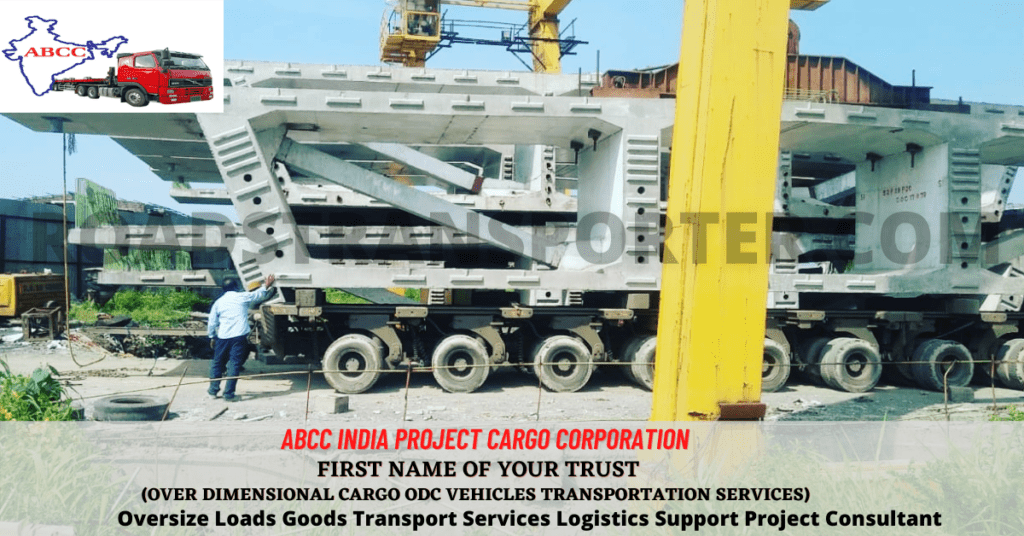

SPMT (Self-Propelled Modular Transporter) trailers and modular hydraulic multi axle trailers are both specialized transportation systems used for moving heavy and oversized loads. While they serve similar purposes, there are distinct differences between the two. Here’s a comparison:

SPMT Trailers:

Self-Propelled:

SPMT trailers are equipped with their own power units and can move independently without the need for a separate towing vehicle. They are driven by hydraulic or electric propulsion systems.

Load Capacity:

SPMT trailers have high load capacities and are capable of transporting extremely heavy loads, often ranging from several hundred to several thousand tons.

Steering Mechanism:

SPMT trailers offer precise and individual steering control for each axle or set of axles. This allows for excellent maneuverability and the ability to navigate tight turns and complex routes.

Modular Design:

SPMT trailers are designed with a modular concept, consisting of individual modules that can be combined and connected to form a larger platform. This modularity allows for flexibility in adapting to various load sizes and configurations.

Versatility:

SPMT trailers can transport a wide range of load types, including oversized and irregularly shaped loads. The modular design allows for customization and adjustment according to specific load requirements.

Modular Hydraulic Multi Axle Trailers:

Towed Configuration:

Modular hydraulic multi axle trailers are typically towed by a separate prime mover or truck. They do not have self-propulsion capabilities and rely on an external power source for movement.

Load Capacity:

While modular hydraulic multi axle trailers also have high load capacities, they are generally suited for loads within the range of several dozen to a few hundred tons per axle line.

Steering Mechanism:

Each axle in a modular hydraulic multi axle trailer can be independently steered or synchronized for improved maneuverability. However, the steering mechanism is hydraulic and controlled by an external power pack unit.

Modular Design:

Similar to SPMT trailers, modular hydraulic multi axle trailers feature a modular design. The trailer can be configured by combining multiple individual axles to create a larger trailer platform capable of accommodating longer or wider loads.

Flexibility:

Modular hydraulic multi axle trailers offer flexibility in adjusting the number of axles and configuring the trailer system to suit different load requirements.

In summary, SPMT trailers are self-propelled and offer independent steering control for each axle, allowing for precise maneuverability. They are suitable for extremely heavy loads and have a high level of customization. Modular hydraulic multi axle trailers, on the other hand, rely on a towing vehicle and have slightly lower load capacities. They offer flexibility through their modular design and can handle a range of heavy loads. The choice between the two depends on the specific load requirements, maneuverability needs, and transportation budget.

Telescopic Trailer V/s Modular Hydraulic Multi Axle Trailer

Telescopic trailers and modular hydraulic multi axle trailers (MHATs) are both types of heavy-duty trailers that are used to transport oversized and overweight cargo. However, there are some key differences between the two types of trailers.

Telescopic trailers have an extendable loading area, which allows them to transport cargo of varying lengths. MHATs, on the other hand, have a fixed loading area, but they can be configured in a variety of ways to accommodate different types of cargo.

Telescopic trailers are typically used to transport cargo that is long and relatively lightweight, such as wind turbine blades and windmill towers. MHATs, on the other hand, are typically used to transport cargo that is heavy and bulky, such as transformers and construction equipment.

Telescopic trailers are typically less expensive than MHATs. However, MHATs are more versatile and can be used to transport a wider variety of cargo.

Here is a table that summarizes the key differences between telescopic trailers and MHATs:

| Characteristic | Telescopic trailer | Modular hydraulic multi axle trailer (MHAT) |

|---|---|---|

| Loading area | Extendable | Fixed |

| Versatility | Less versatile | More versatile |

| Typical cargo | Long and lightweight cargo | Heavy and bulky cargo |

| Cost | Less expensive | More expensive |

Which type of trailer is right for you will depend on your specific needs. If you need to transport long and relatively lightweight cargo, then a telescopic trailer may be a good option for you. If you need to transport heavy and bulky cargo, or if you need a more versatile trailer, then an MHAT may be a better option.

Here are some additional things to consider when choosing between a telescopic trailer and an MHAT:

- The type of terrain that the trailer will be traveling over. MHATs are better suited for rough terrain than telescopic trailers.

- The distance that the trailer will be traveling. If you need to transport cargo over long distances, then an MHAT may be a better option, as they are typically more stable and easier to tow.

- Your budget. MHATs are more expensive than telescopic trailers, but they may be a better investment if you need a more versatile and durable trailer.

It is always best to consult with a qualified professional to help you choose the right type of trailer for your needs.

Drop Deck Trailer V/S Modular Hydraulic Multi Axle Trailer

Drop deck trailers and modular hydraulic multi axle trailers (MHATs) are both types of heavy-duty trailers that are used to transport oversized and overweight cargo. However, there are some key differences between the two types of trailers.

Drop deck trailers have a loading area that is lower than the trailer’s frame. This makes it easier to load and unload cargo, especially heavy and bulky items. Drop deck trailers are typically used to transport cargo such as construction equipment, machinery, and agricultural products.

MHATs have a fixed loading area that can be configured in a variety of ways to accommodate different types of cargo. MHATs are typically used to transport cargo such as transformers, generators, and other heavy industrial equipment.

Here is a table that summarizes the key differences between drop deck trailers and MHATs:

| Characteristic | Drop deck trailer | Modular hydraulic multi axle trailer (MHAT) |

|---|---|---|

| Loading area | Lower than trailer frame | Fixed |

| Versatility | Less versatile | More versatile |

| Typical cargo | Construction equipment, machinery, agricultural products | Transformers, generators, heavy industrial equipment |

| Cost | Less expensive | More expensive |

Which type of trailer is right for you will depend on your specific needs. If you need to transport heavy and bulky cargo, and you need a trailer that is easy to load and unload, then a drop deck trailer may be a good option for you. If you need to transport a wider variety of cargo, or if you need a more versatile trailer, then an MHAT may be a better option.

Here are some additional things to consider when choosing between a drop deck trailer and an MHAT:

- The size and weight of the cargo that you will be transporting.

- The type of terrain that the trailer will be traveling over. MHATs are better suited for rough terrain than drop deck trailers.

- The distance that the trailer will be traveling. If you need to transport cargo over long distances, then an MHAT may be a better option, as they are typically more stable and easier to tow.

- Your budget. MHATs are more expensive than drop deck trailers, but they may be a better investment if you need a more versatile and durable trailer.

ABCC India Project Cargo Corporation provides hydraulic drop deck trailers on rental. They have a fleet of well-maintained trailers that are available for rent at competitive rates.

It is always best to consult with a qualified professional to help you choose the right type of trailer for your needs.

Mechanical Trailer Trolley VS Modular Hydraulic Multi Axle Trailer

Mechanical Trailer Trolley and Modular Hydraulic Multi Axle Trailer are two different types of trailers with distinct characteristics and functionality. Let’s compare them:

Mechanical Trailer Trolley:

Mechanism:

Mechanical trailer trolleys operate using a mechanical system, typically involving manual or motorized winches, pulleys, and levers to control the loading, unloading, and movement of the trailer.

Load Capacity:

Mechanical trailer trolleys generally have a lower load capacity compared to hydraulic multi axle trailers. They are suitable for transporting lighter loads.

Maneuverability:

Mechanical trailer trolleys have limited maneuverability compared to hydraulic multi axle trailers. They typically rely on conventional steering mechanisms and may not have the same level of flexibility in navigating tight turns or complex routes.

Versatility:

Mechanical trailer trolleys are often designed for specific applications and may not offer the same level of modularity or adaptability as hydraulic multi axle trailers. They may have fixed configurations and may not be easily expandable or adjustable to accommodate different load sizes.

Complexity:

While mechanical trailer trolleys can be simpler in design and operation compared to hydraulic trailers, they still require proper maintenance and may need mechanical adjustments or repairs over time.

Modular Hydraulic Multi Axle Trailer:

Mechanism:

Modular hydraulic multi axle trailers utilize advanced hydraulic systems to control the suspension, steering, and load distribution of the trailer. The hydraulic system provides precise control and adjustment of each axle, enhancing maneuverability and load stability.

Load Capacity:

Hydraulic multi axle trailers are designed to handle heavy loads, often with higher load capacities compared to mechanical trailer trolleys. They are suitable for transporting oversized and heavy cargo.

Maneuverability:

Hydraulic multi axle trailers offer superior maneuverability due to the independent steering of each axle. They can navigate tight turns, sharp corners, and complex routes more efficiently, reducing the need for additional equipment or complex maneuvering techniques.

Versatility:

Modular hydraulic multi axle trailers are highly versatile and adaptable. They can be configured and customized to accommodate various load sizes, shapes, and weights. The modular design allows for easy adjustment and reconfiguration of the trailer system based on specific transportation requirements.

Expandability:

Hydraulic multi axle trailers can often be expanded by adding additional modules, allowing for the transportation of longer or wider loads. This expandability adds flexibility and efficiency to transport operations.

In summary, mechanical trailer trolleys are generally simpler, have lower load capacities, and limited maneuverability compared to modular hydraulic multi axle trailers. Hydraulic multi axle trailers offer higher load capacities, enhanced maneuverability, greater versatility, and expandability. The choice between the two depends on the specific transportation requirements, load capacity, maneuverability needs, and budget considerations.

Modular Hydraulic Multi Axle Trailers Advantages

Modular hydraulic axle trailers offer a number of advantages over traditional trailers, including:

Increased load capacity:

Modular hydraulic axle trailers can have a higher load capacity than traditional trailers. This is because they can be equipped with more axles, which can distribute the load more evenly.

Improved maneuverability:

Modular hydraulic axle trailers can be steered, which makes them more maneuverable than traditional trailers. This is important for transporting loads in tight spaces or on winding roads.

Increased safety:

Modular hydraulic axle trailers are equipped with a variety of safety features, such as load sensing, electronic stability control, and anti-lock braking systems. This helps to reduce the risk of accidents.

Flexibility:

Modular hydraulic axle trailers can be customized to meet the specific needs of the user. This includes the ability to change the number of axles, the type of axles, and the configuration of the trailer.

Durability:

Modular hydraulic axle trailers are made from high-quality materials and are designed to withstand the rigors of heavy-duty transportation. This durability means that the trailers can be used for a long period of time without the need for major repairs.

Overall, modular hydraulic axle trailers offer a number of advantages over traditional trailers. These advantages include increased load capacity, improved maneuverability, increased safety, flexibility, and durability. If you are looking for a trailer that can handle heavy loads and provide a safe and efficient transportation solution, then a modular hydraulic axle trailer is a great option.

Modular Hydraulic Multi Axle Trailers Disadvantages

While modular hydraulic axle trailers offer numerous advantages, there are also a few potential disadvantages to consider:

Higher Initial Cost:

Modular hydraulic axle trailers tend to have a higher initial cost compared to traditional trailers. The advanced technology, hydraulics, and steering systems involved in these trailers contribute to their higher price tag. The initial investment may be a significant factor for some businesses, particularly smaller operators.

Maintenance and Complexity:

Modular hydraulic axle trailers require regular maintenance and servicing to ensure optimal performance. The hydraulic systems, steering mechanisms, and suspension components need to be inspected, lubricated, and repaired as necessary. The complexity of these systems may require specialized knowledge and skills, which can increase maintenance costs and the need for trained technicians.

Training and Expertise:

Operating modular hydraulic axle trailers requires specialized training and expertise. The operators need to understand the complex hydraulic and steering systems, as well as safety protocols specific to these trailers. Additional training and certification may be required for operators, which can add to the operational costs and time investment.

Limited Availability and Accessibility:

Modular hydraulic axle trailers may not be as readily available or accessible in all regions. Depending on the location and transportation infrastructure, finding service centers, spare parts, and support for these specialized trailers may be more challenging. This can impact maintenance, repairs, and downtime, especially if the trailers need to be serviced by trained technicians from the manufacturer.

Road Restrictions and Permits:

Modular hydraulic axle trailers may be subject to certain road restrictions and permits due to their size, weight, and load dimensions. Special permissions and escorts may be required for oversize or overweight loads. Complying with these regulations and obtaining the necessary permits can involve additional administrative work and costs.

Complexity in Trailer Configurations:

While the modularity of these trailers allows for flexible configurations, it can also introduce complexities. Determining the optimal configuration, axle spacing, and load distribution for specific cargo can be challenging and time-consuming. Improper configuration or load distribution can affect stability, maneuverability, and overall safety.

It’s essential for businesses to carefully evaluate these potential disadvantages against their specific transportation needs, budget, and operational capabilities. Considering these factors will help determine if modular hydraulic axle trailers are the right choice for their requirements and if the advantages outweigh the disadvantages.

What is girder bridge trolley trailer in odc cargo transportation and why required

A girder bridge trolley trailer is a type of trailer that is used to transport heavy loads over girder bridges. It is a specialized trailer that is designed to be able to support the weight of the load and to maneuver the load over the bridge.

Here are some of the reasons why girder bridge trolley trailers are required in ODC cargo transportation:

To support the weight of heavy loads:

Girder bridge trolley trailers are very strong and can support the weight of even the heaviest loads. This is important for ODC transportation, as the loads that are transported can be very heavy.

To accommodate the width of wide loads:

Girder bridge trolley trailers can be customized to accommodate the width of wide loads. This is important for ODC transportation, as the loads that are transported can be very wide.

To provide a smooth ride for the load:

Girder bridge trolley trailers are designed to provide a smooth ride for the load. This is important for ODC transportation, as the loads that are transported can be very sensitive to vibrations.

To allow the load to be transported over girder bridges:

Girder bridge trolley trailers are designed to be able to maneuver the load over girder bridges. This is important, as girder bridges can be very narrow and difficult to navigate.

Here are some of the benefits of using girder bridge trolley trailers in ODC cargo transportation:

Increased load capacity:

Girder bridge trolley trailers can have a higher load capacity than other types of trailers. This means that they can be used to transport heavier loads.

Improved maneuverability:

Girder bridge trolley trailers can be more maneuverable than other types of trailers. This is important for ODC transportation, as the loads that are transported can be very large and difficult to maneuver.

Reduced environmental impact:

Girder bridge trolley trailers can have a lower environmental impact than other types of trailers. This is because they can be made from recycled materials and can be designed to be more energy-efficient.

Overall, girder bridge trolley trailers are a valuable tool for ODC cargo transportation. They can support heavy loads, accommodate wide loads, and provide a smooth ride for the load. They also have a lower environmental impact than other types of trailers.

Here are some of the features of a girder bridge trolley trailer:

A strong frame:

The frame of a girder bridge trolley trailer is very strong and can support the weight of even the heaviest loads.

Wide tires:

The tires on a girder bridge trolley trailer are wide and provide a good grip on the ground. This is important, as the trailer will be traveling over uneven surfaces.

Steering system:

The steering system on a girder bridge trolley trailer is very precise and allows the trailer to be maneuvered easily.

Brakes:

The brakes on a girder bridge trolley trailer are very powerful and can stop the trailer quickly in an emergency.

Overall, girder bridge trolley trailers are a valuable tool for ODC cargo transportation. They are strong, maneuverable, and have a low environmental impact. If you are transporting heavy loads over girder bridges, then a girder bridge trolley trailer is the best option for you.

Maximum Usable Modular Hydraulic Multi Axle Trailers in India

The maximum usable modular hydraulic axle trailers in India is currently limited to single modules of eight axle lines with two axles in a row. This is according to the Code of Practice for Type Approval of Modular Hydraulic Trailers towed by Puller Tractor of Category N3, which was formulated by the Ministry of Road Transport and Highways (MORTH) in 2019.

The code states that “modular hydraulic trailers upto and including single module of eight axle lines with two axles in a row” are the only type of modular hydraulic trailers that are currently approved for use in India. This means that trailers with more than eight axle lines, or with more than two axles in a row, are not currently approved for use in India.

However, MORTH is currently considering a proposal to increase the maximum number of axle lines allowed for modular hydraulic trailers in India. If the proposal is approved, the maximum number of axle lines would be increased to 12. This would allow for the use of larger and more powerful modular hydraulic trailers in India.

The proposal to increase the maximum number of axle lines for modular hydraulic trailers in India is still under consideration, and it is not yet clear when or if the proposal will be approved. However, if the proposal is approved, it would significantly increase the capabilities of modular hydraulic trailers in India.

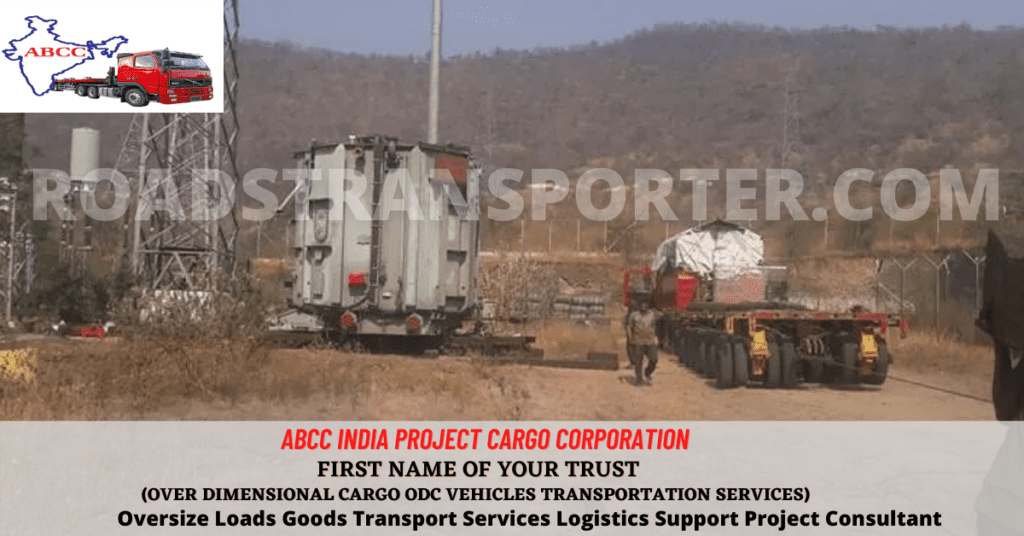

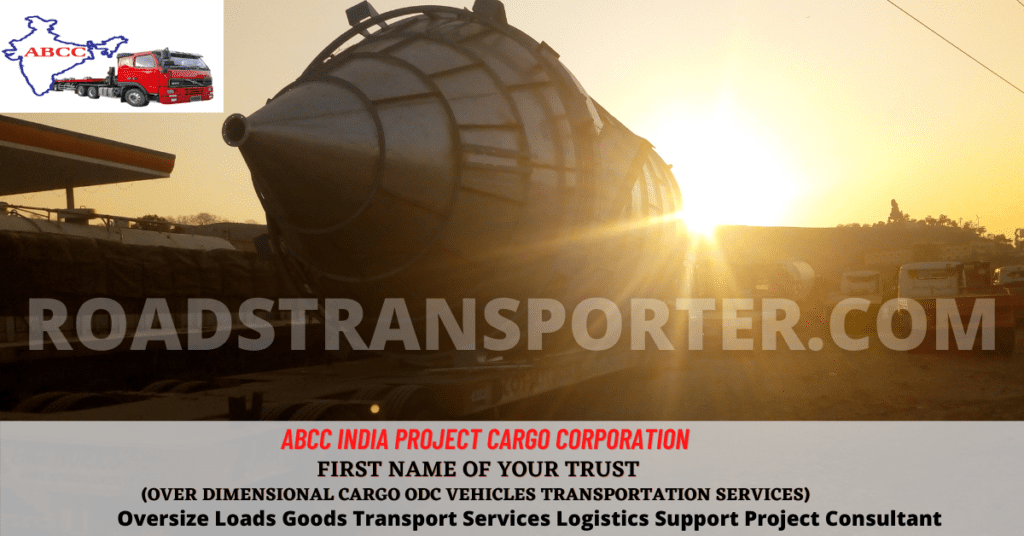

ABCC INDIA Project Cargo Corporation Role in Modular Hydraulic Multi Axle Trailers industry in India

ABCC INDIA Project Cargo Corporation (ABCC India) is a leading supplier of modular hydraulic multi-axle trailers in India. They have been in the business for over +40 years and have a strong reputation for quality and reliability.

ABCC India offers a wide range of modular hydraulic multi-axle trailers to meet the needs of their customers. They have trailers that can handle loads of up to 1,000 tonnes and can be customized to meet specific requirements.

ABCC India is also a leading supplier of other heavy haulage equipment, such as lowboy trailers, side-dump trailers, and flatbed trailers. They have a team of experienced professionals who can help you choose the right trailer for your needs and ensure that it is delivered on time and within budget.

Here are some of the roles of ABCC India in the modular hydraulic multi axle trailers industry in India and (Indo Saarc Countries ):

Supplier:

ABCC India is a leading supplier of modular hydraulic multi axle trailers in India. They have a wide range of trailers to choose from and can customize a trailer to meet specific requirements.

Distributor:

ABCC India also distributes modular hydraulic multi axle trailers from other manufacturers. This allows them to offer a wider range of trailers to their customers.

Service provider:

ABCC India also provides maintenance and repair services for modular hydraulic multi axle trailers. This ensures that their customers’ trailers are always in good working condition.

Consultant:

ABCC India can also provide consulting services to help customers choose the right trailer for their needs. They have a team of experienced professionals who can help you assess your needs and find the right trailer for your budget.

ABCC India is a leading player in the modular hydraulic multi axle trailers industry in India. They offer a wide range of trailers, services, and consulting services to their customers. They are committed to providing their customers with the best possible products and services.

Here are some of the specific ways in which ABCC India is contributing to the modular hydraulic multi axle trailers industry in India:

Providing high-quality trailers:

ABCC India uses high-quality materials and components in their trailers, which ensures that they are durable and reliable. They also offer a wide range of customization options, so customers can choose a trailer that meets their specific needs.

Offering competitive prices:

ABCC India offers competitive prices on their trailers, which makes them a cost-effective option for businesses. They also offer discounts for bulk orders and government agencies.

Providing excellent customer service:

ABCC India has a team of experienced professionals who are dedicated to providing excellent customer service. They are available to answer customer questions and help them choose the right trailer for their needs.

Promoting the use of modular hydraulic multi axle trailers:

ABCC India is committed to promoting the use of modular hydraulic multi axle trailers in India. They believe that these trailers offer a number of advantages over traditional trailers, such as increased load capacity, improved maneuverability, and reduced environmental impact.

Ministry of Road Transport and Highways of India Morth Terms and condition hydraulic axle transportation in India

For the most accurate and up-to-date information, please refer to the official guidelines and regulations issued by the Ministry of Road Transport and Highways (MORTH) of India.

- Permits and Approvals: Hydraulic axle transportation in India typically requires obtaining appropriate permits and approvals from the concerned authorities. These permits may specify the routes, load limits, and validity periods.

- Vehicle Specifications: The hydraulic axle vehicle used for transportation must adhere to the specifications prescribed by MORTH. This includes complying with axle configurations, dimensions, and load-bearing capacity guidelines.

- Load Restrictions: There are specific load restrictions for hydraulic axle vehicles in terms of Gross Vehicle Weight (GVW) and axle loads. Overloading is strictly prohibited to ensure road safety and infrastructure integrity.

- Route Restrictions: Certain roads or bridges may have restrictions on heavy-load transportation, and hydraulic axle vehicles may need to follow alternate routes or obtain special permissions to use restricted routes.

- Speed Limits: Hydraulic axle vehicles are typically subject to speed restrictions to maintain safety during transportation.

- Safety Measures: Adequate safety measures must be taken during hydraulic axle transportation, including the use of appropriate securing mechanisms to prevent the load from shifting or falling.

- Escorts and Flags: Depending on the size and weight of the load, escorts and flags may be required to accompany the vehicle to alert other road users and ensure safe passage.

- Compliance with Traffic Rules: Vehicle operators must strictly adhere to all traffic rules and regulations while transporting goods using hydraulic axle vehicles.

- Timings: There may be specific time restrictions during which hydraulic axle transportation is permitted, possibly to avoid peak traffic hours or other congested periods.

- Penalties: Non-compliance with the terms and conditions may lead to penalties or legal consequences as per the applicable laws and regulations.

Again, it’s crucial to refer to the official documents and guidelines issued by the Ministry of Road Transport and Highways to get the most accurate and up-to-date information on the terms and conditions for hydraulic axle transportation in India.

Here are some of the Morth terms and conditions for hydraulic axle transportation in India:

- The axle must be properly packaged and secured to the transport vehicle.

- The transport vehicle must be equipped with a hydraulic hoist or crane to load and unload the axle.

- The axle must be transported in a covered vehicle to protect it from the elements.

- The axle must be transported at a safe speed and under the supervision of a qualified driver.

- The axle must be inspected upon arrival to ensure that it has not been damaged during transportation.

In addition to these terms and conditions, the following may also apply:

- The axle must be transported in accordance with the relevant government regulations.

- The axle must be insured for its full value during transportation.

- The customer is responsible for any costs associated with damage to the axle during transportation.

It is important to note that these are just some general terms and conditions. The specific terms and conditions may vary depending on the particular axle and the transportation company. It is always advisable to check with the transportation company in advance to confirm the terms and conditions that will apply to your shipment.

Here are some additional tips for transporting hydraulic axles in India:

- Make sure that the axle is properly cleaned and free of debris before it is transported.

- Use a high-quality packaging material to protect the axle from damage.

- Mark the packaging clearly with the weight and dimensions of the axle.

- Notify the transportation company in advance of the axle’s arrival so that they can make the necessary arrangements.

By following these tips, you can help to ensure that your hydraulic axle arrives at its destination safely and in good condition.

Prime Movers available for modular hydraulic multi axle trailer transportation `

Volvo prime mover models with their specifications and working weight capacity for hydraulic axle trailer transportation:

| Model | Engine | Horsepower | Torque (lb-ft) | Working Weight Capacity (ton) |

|---|---|---|---|---|

| Volvo VNL 780 | Cummins X15 Efficiency | 605 | 2,250 | 120 |

| Volvo VHD 880 | Cummins X15 Efficiency | 605 | 2,250 | 140 |

| Volvo VNX 880 | Cummins X15 Efficiency | 605 | 2,250 | 160 |

Scania prime mover models with their specifications and working weight capacity for hydraulic axle trailer transportation:

| Model | Engine | Horsepower | Torque (lb-ft) | Working Weight Capacity (ton) |

|---|---|---|---|---|

| Scania S730 | DC16 16L V8 | 730 hp | 3,500 Nm | 120 |

| Scania R770 | DC16 16L V8 | 770 hp | 3,700 Nm | 140 |

| Scania G500 | DC13 13L 6-cylinder | 500 hp | 2,550 Nm | 160 |

Mercedes-Benz prime mover models with their specifications and working weight capacity for hydraulic axle trailer transportation:

| Model | Engine | Horsepower | Torque (lb-ft) | Working Weight Capacity (ton) |

|---|---|---|---|---|

| Mercedes-Benz Actros 1863 LS | OM 471 | 625 hp | 2,400 Nm | 120 |

| Mercedes-Benz Actros 2063 LS | OM 473 | 730 hp | 3,000 Nm | 140 |

| Mercedes-Benz Arocs 3363 S | OM 473 | 730 hp | 3,000 Nm | 160 |

Eicher prime mover models with their specifications and working weight capacity for hydraulic axle trailer transportation:

| Model | Engine | Horsepower | Torque (lb-ft) | Working Weight Capacity (ton) |

|---|---|---|---|---|

| Eicher Pro 6035T | Cummins ISX15+ | 605 hp | 2,250 Nm | 120 |

| Eicher Pro 6040T | Cummins X15 Efficiency | 605 hp | 2,250 Nm | 140 |

| Eicher Pro 6045T | Cummins X15 Efficiency | 605 hp | 2,250 Nm | 160 |

Tata prime mover models with their specifications and working weight capacity for hydraulic axle trailer transportation:

| Model | Engine | Horsepower | Torque (lb-ft) | Working Weight Capacity (ton) |

|---|---|---|---|---|

| Tata Prima LX 5530.S | Cummins ISX15+ | 565 hp | 2,050 Nm | 120 |

| Tata Prima LX 6030.S | Cummins X15 Efficiency | 605 hp | 2,250 Nm | 140 |

| Tata Prima LX 6530.S | Cummins X15 Efficiency | 655 hp | 2,450 Nm | 160 |

Ashok Leyland prime mover models with their specifications and working weight capacity for hydraulic axle trailer transportation:

| Model | Engine | Horsepower | Torque (lb-ft) | Working Weight Capacity (ton) |

|---|---|---|---|---|

| Ashok Leyland 4923R | Cummins ISX15+ | 565 hp | 2,050 Nm | 120 |

| Ashok Leyland 5023TR | Cummins X15 Efficiency | 605 hp | 2,250 Nm | 140 |

| Ashok Leyland 5123TR | Cummins X15 Efficiency | 655 hp | 2,450 Nm | 160 |

These three models are the most powerful and capable prime movers, making them ideal for hydraulic axle trailer transportation. They have a working weight capacity of up to 160 to 200 tons, which means they can pull even the heaviest loads.

Modular Hydraulic Axle Trailer Mobilisation Charges India

Modular hydraulic axle trailer (MHAT) mobilisation charges in India vary depending on a number of factors, including:

- The distance between the pick-up and delivery locations.

- The size and weight of the load.

- The number of axles on the trailer.

- The type of terrain that the trailer will be traveling over.

- The time of year (mobilisation charges are typically higher during peak season).

Here are some estimated mobilisation charges for MHATs in India:

| Distance | Mobilisation charge |

|---|---|

| Less than 100 km | Rs. 10,000 – Rs. 20,000 |

| 100-200 km | Rs. 20,000 – Rs. 30,000 |

| 200-300 km | Rs. 30,000 – Rs. 40,000 |

| More than 300 km | Rs. 40,000 and above |

Modular Hydraulic Axle Trailer Mobilisation Tentative Charges India

It is important to note that these are just estimates, and the actual mobilisation charge may vary depending on the specific requirements of the job. It is always best to contact a reputable MHAT transportation company to get an accurate quote.

Here are some tips for getting the best possible mobilisation charge for your MHAT transportation:

- Be as specific as possible when requesting a quote. Include the exact pick-up and delivery locations, the size and weight of the load, the number of axles on the trailer, and the type of terrain that the trailer will be traveling over.

- Be flexible with your scheduling. If possible, schedule your transportation during the off-season to get a lower price.

- Get quotes from multiple companies before making a decision. This will help you to ensure that you are getting the best possible price.

Please note that the above information is for informational purposes only and should not be construed as financial advice.

Modular Hydraulic Axle Trailer Mobilisation Charges India to Other Countries

Here are some estimated mobilisation charges for MHATs from India to other countries:

| Country | Mobilisation charge |

|---|---|

| USA | Rs. 10,00,000 – Rs. 15,00,000 |

| UK | Rs. 12,00,000 – Rs. 17,00,000 |

| Saarc Countries | Rs. 13,00,000 – Rs. 18,00,000 |

It is important to note that these are just estimates, and the actual mobilisation charge may vary depending on the specific requirements of the job. It is always best to contact a reputable MHAT transportation company to get an accurate quote.

Here are some tips for getting the best possible mobilisation charge for your MHAT transportation from India to other countries:

- Be as specific as possible when requesting a quote. Include the exact pick-up and delivery locations, the size and weight of the load, the number of axles on the trailer, the type of terrain that the trailer will be traveling over, and the desired mode of transportation.

- Be flexible with your scheduling. If possible, schedule your transportation during the off-season to get a lower price.

- Get quotes from multiple companies before making a decision. This will help you to ensure that you are getting the best possible price.

Please note that the above information is for informational purposes only and should not be construed as financial advice.

Additional information:

- The mobilisation charges for MHAT transportation from India to other countries are typically higher than the mobilisation charges for domestic transportation. This is because international transportation involves additional costs, such as customs clearance and shipping fees.

- The mobilisation charges for MHAT transportation may also be higher for certain countries, such as those with remote locations or difficult terrain.

- It is important to factor in the cost of mobilisation charges when budgeting for your MHAT transportation.

Modular hydraulic axle trailer price in India

Here is a chart of the prices of modular hydraulic axle trailers in India from always available brands:

| Brand | Model | Price (INR) |

|---|---|---|

| Goldhofer | PST/SL-E | ₹1.5 crore to ₹2 crore |

| VMT | HMA 100 | ₹1 crore to ₹1.5 crore |

| Tractac | THP | ₹90 lakh to ₹1.4 crore |

| TII | Multi-Axle Trailer | ₹80 lakh to ₹1.2 crore |

| ABCC India Project Cargo Corporation | Hydraulic Axle Trailer | ₹60 lakh to ₹1 crore |

Please note that these prices are approximate and may vary depending on the specific model, configuration, and dealer.

Goldhofer is a German manufacturer of heavy-duty transport equipment, including modular hydraulic axle trailers. Goldhofer trailers are known for their high quality and reliability, and they are used by some of the largest construction and transportation companies in the world.

VMT is an Indian manufacturer of heavy-duty transport equipment, including modular hydraulic axle trailers. VMT trailers are known for their durability and affordability, and they are widely used by construction and transportation companies in India.

Tractac is a Spanish manufacturer of heavy-duty transport equipment, including modular hydraulic axle trailers. Tractac trailers are known for their innovative design and features, and they are used by many leading construction and transportation companies around the world.

TII is an Indian manufacturer of heavy-duty transport equipment, including modular hydraulic axle trailers. TII trailers are known for their quality and reliability, and they are widely used by construction and transportation companies in India.

ABCC India Project Cargo Corporation Famous name in Indian heavy hauling industry for hydraulic and mechanical trailers manufacturer ,second hand trailer reseller and efficient transporter for all types over dimensional cargo transportation expected urban rural metro and remote location .

When choosing a modular hydraulic axle trailer, it is important to consider the specific needs of your business. Factors to consider include the capacity of the trailer, the type of cargo you will be transporting, the terrain you will be driving on, and your budget.

Conclusion

Overall, ABCC India is a leading player in the modular hydraulic multi axle trailers industry in India. They are committed to providing their customers with the best possible products and services, and they are helping to promote the use of these trailers in India.

Modular Hydraulic Multi-Axle Trailer FAQ

How to work Hydraulic axle trailer on road after load ?

To work a hydraulic axle trailer on the road after load, you need to follow these steps:

Check the load. Make sure that the load is properly secured and evenly distributed on the trailer.

Raise the axles. Use the hydraulic system to raise the axles to the desired height. The axles should be raised so that the tires are clear of the ground.

Connect the trailer to the tractor. Connect the trailer to the tractor using the fifth wheel or kingpin.

Test the brakes. Test the brakes to make sure that they are working properly.

Drive the trailer. Drive the trailer slowly and carefully until you reach your destination.

Here are some additional tips for working a hydraulic axle trailer on the road:

Be aware of the height of your load. Make sure that you do not hit any bridges or overpasses.

Make sure that the trailer is properly balanced. If the trailer is unbalanced, it can be difficult to control.

Be careful when turning corners. The trailer may swing wide when turning.

Drive slowly and carefully. Hydraulic axle trailers can be more difficult to control than standard trailers.

If you are unsure about how to operate a hydraulic axle trailer, it is best to consult with a professional.

Please note that I am not a certified truck driver or trailer operator. This information is for informational purposes only and is not a substitute for professional training.

How to work Puller Prime Movers on Hydraulic axle trailer transportation on road after load ?

To work puller prime movers on hydraulic axle trailer transportation on road after load, you need to follow these steps:

Position the puller prime mover. Position the puller prime mover in front of the hydraulic axle trailer. The puller prime mover should be centered in front of the trailer and the fifth wheel should be aligned with the kingpin.

Connect the puller prime mover to the trailer. Connect the puller prime mover to the trailer using the fifth wheel or kingpin.

Raise the axles. Use the hydraulic system to raise the axles of the trailer. The axles should be raised so that the tires are clear of the ground.

Connect the hydraulic lines. Connect the hydraulic lines from the puller prime mover to the hydraulic system of the trailer.

Test the brakes. Test the brakes of the trailer to make sure that they are working properly.

Drive the trailer. Drive the trailer slowly and carefully until you reach your destination.

Here are some additional tips for working puller prime movers on hydraulic axle trailer transportation on road:

Be aware of the height of your load. Make sure that you do not hit any bridges or overpasses.

Make sure that the trailer is properly balanced. If the trailer is unbalanced, it can be difficult to control.

Be careful when turning corners. The trailer may swing wide when turning.

Drive slowly and carefully. Hydraulic axle trailers can be more difficult to control than standard trailers.

Be aware of the surroundings and other road users. Puller prime movers are large and powerful vehicles, so it is important to be safe and responsible when operating them.

If you are unsure about how to operate a puller prime mover or hydraulic axle trailer, it is best to consult with a professional.

Please note that I am not a certified truck driver or trailer operator. This information is for informational purposes only and is not a substitute for professional training.

How does a hydraulic axle work?

A hydraulic axle uses a hydraulic system to raise and lower the axle, which can be useful for a variety of purposes, such as:

Adjusting the ride height of a vehicle. This can be useful for off-road vehicles or vehicles that carry heavy loads.

Improving traction in slippery conditions. By lowering the axle, you can increase the weight on the tires, which can improve traction.

Reducing drag. By raising the axle, you can reduce the drag of the vehicle, which can improve fuel economy.

Hydraulic axles are typically used on heavy-duty vehicles, such as trucks, buses, and trailers. They can also be found on some off-road vehicles and SUVs.

Here is a simplified overview of how a hydraulic axle works:

The hydraulic axle has a hydraulic cylinder that is connected to the axle housing.

Hydraulic fluid is pumped into the cylinder to raise the axle.

A release valve is opened to lower the axle.

The hydraulic system is powered by a hydraulic pump, which is typically driven by the engine.

Hydraulic axles are controlled by a variety of means, such as a switch in the cab, a remote control, or a computer system.

Here are some of the benefits of using hydraulic axles:

Improved ride quality

Increased traction

Reduced drag

Increased ground clearance

Improved maneuverability

However, hydraulic axles can also be more expensive and complex to maintain than traditional axles.

Overall, hydraulic axles offer a number of advantages over traditional axles, but they are also more expensive and complex. If you need a vehicle that can handle heavy loads, operate in off-road conditions, or adjust its ride height, then a hydraulic axle may be a good option for you.

What is hydraulic axle capacity? (old and new models)

The hydraulic axle capacity is the maximum weight that the axle can support. The capacity of a hydraulic axle will vary depending on the make, model, and year of the axle.

Here is a general overview of the hydraulic axle capacity for old and new models:

Old models

Hydraulic axles from the 1970s and 1980s typically had a capacity of around 20,000 pounds per axle.

Hydraulic axles from the 1990s and early 2000s typically had a capacity of around 30,000 pounds per axle.

New models

Hydraulic axles from the mid-2000s and later typically have a capacity of around 40,000 pounds per axle or more.