What is Steel ?

Steel is a very strong and versatile metal alloy. The main component is iron, but it also contains carbon, usually less than 2%. This combination makes steel much stronger and more durable than iron on its own. Small amounts of other elements are often added to steel to give it specific properties. For instance, chromium can make steel more resistant to corrosion.

Steel is the world’s most important building and engineering material. It’s all around us in everything from cars and bridges to appliances and medical instruments. Because it’s so strong and durable, steel can be recycled many times without losing its properties.

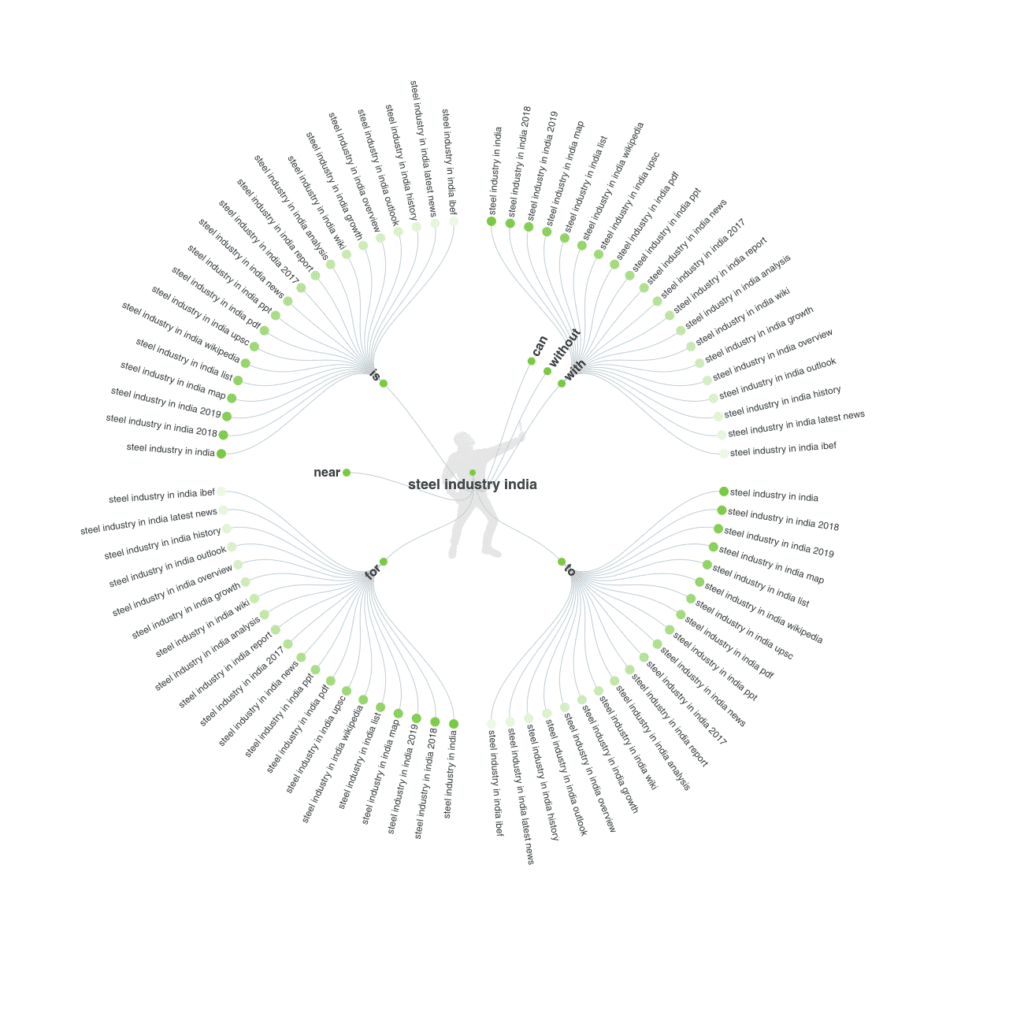

Here is a chart summarizing different types of steel, their uses, pros and cons, and price range:

| Type of Steel | Uses | Pros | Cons | Price Range (USD per ton) |

|---|---|---|---|---|

| Carbon Steel | – Construction (beams, pipes, rebar) – Vehicles (frames, engines) – Tools (hammers, wrenches) | Strong and affordable, Versatile – can be shaped and welded, Recyclable | Susceptible to rust, Lower strength compared to some other steels | $400 – $1,200 |

| Alloy Steel | – High-performance vehicles (gears, crankshafts) – Heavy machinery (cranes, bulldozers) – Pressure vessels – Cutting tools | Higher strength and wear resistance, Can be customized for specific properties | More expensive than carbon steel, May be more difficult to weld | $800 – $2,500 |

| Stainless Steel | – Appliances (sinks, refrigerators) – Cutlery and cookware – Medical instruments – Building facades | Excellent corrosion resistance, Attractive finish | More expensive than carbon steel, Lower strength, Can be difficult to machine | $1,000 – $4,000 |

| Tool Steel | – Cutting tools (drills, blades) – Dies and molds – Wear plates | Very high hardness and wear resistance, Holds a sharp edge | Brittle and can shatter, Expensive | $2,000 – $6,000 |

Who When and Why Invented Steel ?

Steel wasn’t invented by a single person in a single moment, but rather developed over time and across different cultures. Here’s a breakdown:

Early forms of steel:

Around 6th century BC, India produced a crucible steel called wootz, known for its sharpness and distinctive patterns.

China also developed methods for creating high-quality steel around the 2nd century BC, possibly using techniques similar to the later Bessemer process.

Modern Steel Production:

While not the inventor of steel itself, Sir Henry Bessemer of England is credited with developing the Bessemer process in 1855. This process revolutionized steel production by allowing large quantities of inexpensive steel to be manufactured.

The Bessemer process had limitations, and other inventors like Sidney Gilchrist-Thomas and Pierre and Emile Martin developed improvements throughout the 19th century.

So, steel’s development was a collaborative effort across centuries and continents, with Bessemer playing a key role in ushering in the modern steel era. The main reason for these advancements was the desire for a stronger and more versatile material than iron on its own.

History of Steel Industry in India

The history of the Indian steel industry is a fascinating journey of early attempts, colonial influence, and eventual rise to become a global leader. Here’s a breakdown of the key eras:

Early Attempts (1800s):

1800s: The first attempts to establish a modern steel industry in India began in the early 1800s. These efforts faced challenges and weren’t entirely successful.

1870s: A breakthrough came with the establishment of the Bengal Iron Works Company in the 1870s, marking the beginning of modern steel production in India.

Colonial Era and TATA Steel (1900s):

1907: A defining moment arrived with the founding of Tata Iron and Steel Company (TISCO) by Jamsetji Nusserwanji Tata. TISCO, now known as Tata Steel, played a pivotal role in shaping the Indian steel industry.

Pre-Independence: During the British Raj, the steel industry saw limited growth, primarily focused on serving colonial needs. TISCO remained a major player throughout this period.

Post-Independence Growth (1950s onwards):

1950s: Following independence, the Indian government prioritized developing a robust steel industry. This led to the establishment of several public sector steel plants like Bhilai, Rourkela, and Durgapur with collaboration from USSR, Germany, and Britain.

1970s: The Steel Authority of India (SAIL) was formed in 1973 to manage these public sector plants, further consolidating the government’s role in the industry.

Liberalization and Modernization (1990s onwards): India’s economic liberalization in the 1990s led to increased private sector participation and modernization efforts within the steel industry.

Today: India is now the second-largest steel producer globally, demonstrating the remarkable growth of the industry since its early days.

Here are some additional points of interest:

Focus on Public Sector: The initial focus on public sector plants played a crucial role in laying the foundation for the industry’s growth.

Private Sector Participation: The increasing involvement of the private sector in recent decades has fostered innovation and competition.

Challenges: The industry continues to face challenges like resource availability, environmental concerns, and import competition.

Overall, the Indian steel industry has come a long way, transforming from early endeavors to a global powerhouse. It’s a story of continuous development, adaptation, and striving for self-sufficiency in this vital material.

Evolution of Steel Industry in India

| Timeline | Description |

|---|---|

| Early 1800s | First attempts to establish a modern steel industry |

| 1870s | Establishment of Bengal Iron Works Company – Beginning of modern steel production |

| 1907 | Founding of Tata Iron and Steel Company (TISCO) by Jamsetji Nusserwanji Tata |

| Pre-Independence | Limited growth under British Raj, TISCO remains a major player |

| 1950s | Government prioritizes steel industry, establishment of public sector plants |

| 1973 | Formation of Steel Authority of India (SAIL) to manage public sector plants |

| 1990s onwards | Liberalization, increased private sector participation and modernization |

| Today | India becomes the second-largest steel producer globally |

The Indian steel industry has come a long way, transforming from early endeavors to a global powerhouse. It’s a story of continuous development, adaptation, and striving for self-sufficiency in this vital material.

Fact About Indian Steel Industry

Here are a few interesting facts about the Indian Steel Industry:

Ancient Roots: While modern steel production began in the 1800s, India has a much older connection to steel. Around the 6th century BC, India produced a crucible steel called wootz, known for its sharpness and distinctive patterns, used in sword making.

Growth Champion: The Indian steel sector has seen phenomenal growth in recent decades. Production has increased by over 75% since 2008, and domestic steel demand has risen by almost 80%.

Self-Reliance: India boasts the world’s fifth-largest reserves of iron ore, a crucial raw material for steel production. This resource endowment helps support domestic steel production and reduces dependence on imports.

Export Powerhouse: India’s steel industry is not just import-substituting, it’s also a major exporter. In FY22 (financial year 2022), India’s steel exports rose by a whopping 25.1% compared to the previous year.

Sustainable Efforts: The Indian steel industry is increasingly focusing on sustainability initiatives. This includes adopting cleaner technologies to reduce emissions and exploring the use of recycled steel scrap.

Top Steel Companies in North East India

| Company Name | Location | Ownership | Details | Contribution |

|---|---|---|---|---|

| Maithan Steel and Power Limited | Dispur, Assam | Private | Primarily a power company with a small steel melting unit | Limited steel production capacity |

| M S Shillong Ispat & Rolling Mills | Kumarpara, Tripura | Private | Steel re-rolling mill | Steel processing, not primary production |

| Megha Shakti Steel Company | G S Road, Guwahati, Assam | Private | Steel re-rolling mill | Steel processing, not primary production |

Top Steel Companies in North India

| Company Name | Headquarters | Ownership | Manufacturing Capability (Million Tonnes per Annum) | Contribution to Industry | Why Different |

|---|---|---|---|---|---|

| Tata Steel Limited | Jamshedpur, Jharkhand | Private | 34.8 (2023) | – Pioneered modern steel production in India <br> – Focus on innovation and high-quality steel | – Diverse product portfolio including long products, flat products, and special steels |

| Jindal Steel and Power Limited (JSPL) | New Delhi | Private | 6.7 (2023) | – Strong focus on sustainable steelmaking practices | – Expertise in various steel grades like pipes, plates, and rails |

| Steel Authority of India Limited (SAIL) | New Delhi | Public Sector | 21.4 (2023) | – Largest steel producer in the public sector | – Wide reach across various steel products |

| National Mineral Development Corporation Steel Limited (NMDC Steel Limited) | Hyderabad, Telangana (Registered Office) | Public Sector | 3.5 (2023) | – Vertically integrated steel plant with captive iron ore mines | – Focus on high-grade pellet production |

| JSW Steel Limited | Mumbai, Maharashtra (Registered Office) | Private | 18.1 (2023) | – Rapidly growing steel producer with a strong domestic presence | – Expertise in flat products like plates and coils |

Top Steel Companies in Western India

| Company Name | Headquarters | Ownership | Manufacturing Capability (Million Tonnes per Annum) | Contribution to Industry | Why Different |

|---|---|---|---|---|---|

| JSW Steel Limited* | Mumbai, Maharashtra (Registered Office) | Private | 18.1 (2023) | Rapidly growing steel producer with a strong domestic presence | Expertise in flat products like plates and coils |

| ArcelorMittal Nippon Steel India Limited (AM/NS India) | Mumbai, Maharashtra | Joint Venture (ArcelorMittal & Nippon Steel) | 12 (2023) | Focus on high-end automotive steel and technology transfer | Collaboration between global steel giants |

| Essar Steel India Limited | Mumbai, Maharashtra | Private | 10.0 (2023) | Flat steel products with a focus on exports | Strong export presence |

| Viraj Steel Limited | Pune, Maharashtra | Private | 2.5 (2023) | Long products like TMT bars and structurals | Focus on specific steel products within the long product segment |

| Mukand Limited | Thane, Maharashtra | Private | 1.0 (2023) | Speciality steel products like alloy steel and tool steel | Expertise in niche steel segments |

Top Steel Companies in South India

| Company Name | Location | Ownership | Manufacturing Capability (Approx. Annual Capacity) | Contribution to Industry | Why Different |

|---|---|---|---|---|---|

| Salem Steel Plant (Unit of SAIL) | Salem, Tamil Nadu | Public Sector (SAIL) | 0.3 Million Tonnes | Contributes to regional steel needs | Public sector undertaking, caters to regional demand |

| Kalyani Steel Limited | Pune, Maharashtra (Registered Office) | Private | 2 Million Tonnes | Primarily a manufacturer of long products – TMT bars and structurals | Plays a role in supplying long products to South India (plants in Andhra Pradesh) |

| Shyam Steel Industries Limited | Agarpara, West Bengal (Registered Office) | Private | 1.2 Million Tonnes | Focus on long products like TMT bars and wires | Fulfills regional demand for long products (plants in Tamil Nadu) |

| Mishra Dhatu Nigam Limited (MIDHANI) | Hyderabad, Telangana | Public Sector | Limited steelmaking capacity | Specializes in high-performance alloys and superalloys | Niche player in specialty steel crucial for aerospace and defense |

| The Ramkrishna Mills (Bhadravathi) Limited | Bhadravati, Karnataka | Public Sector | Not a major steel producer | Focus on special steel products like ferroalloys and stainless steel | Niche player in specialty steel catering to specific needs |

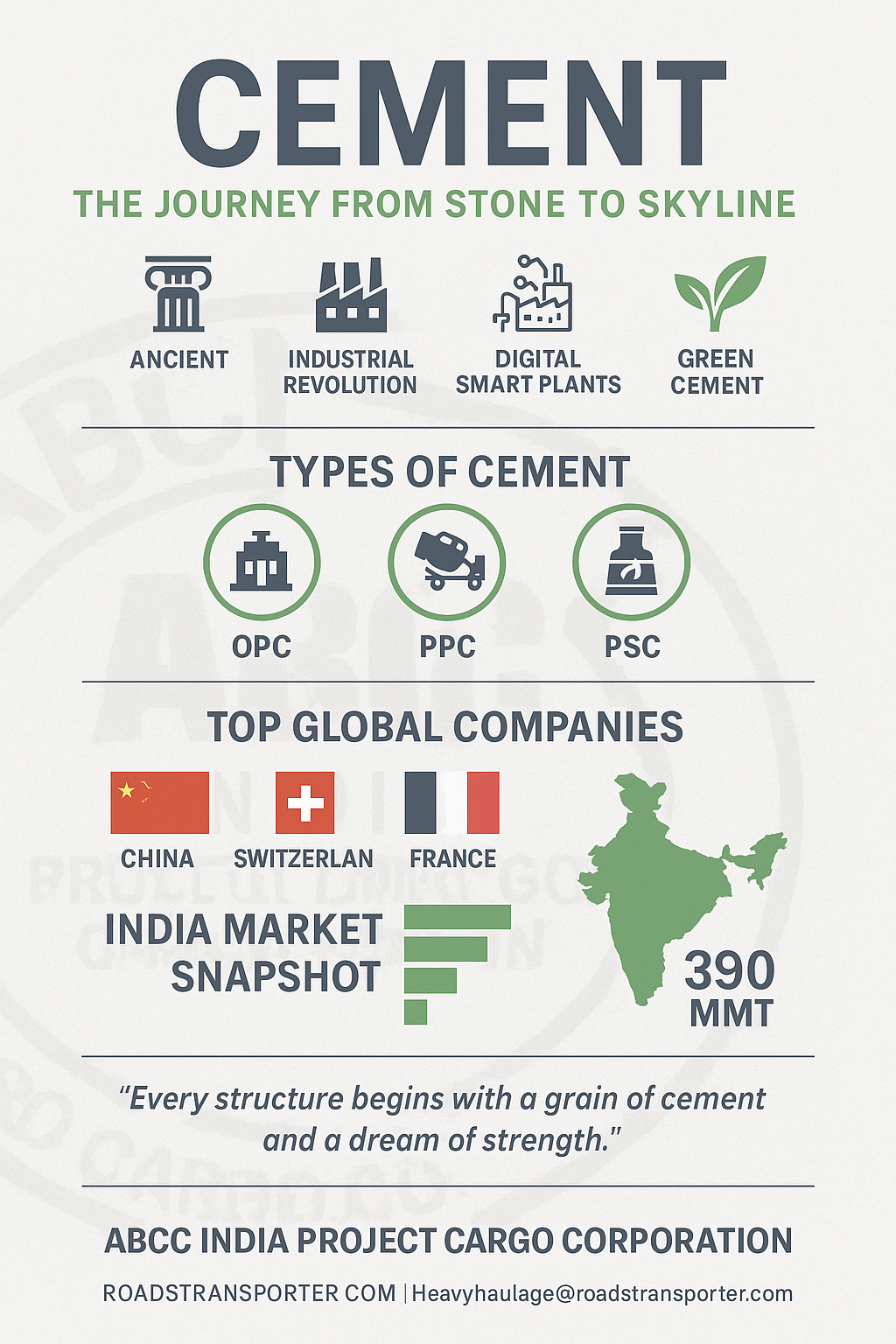

ABCC India Project Cargo Best for Steel Industries Goods Transportation

ABCC India Project Cargo Corp is a reputed logistics company known for its excellence in transporting goods for various industries, including the steel sector. With a strong emphasis on reliability, efficiency, and safety, ABCC India Project Cargo has established itself as a trusted partner for businesses seeking seamless transportation solutions for their steel industry goods.

One of the key strengths of ABCC India Project Cargo lies in its extensive experience in handling project cargo, particularly within the steel industry. Over the years, the company has amassed invaluable expertise in managing the unique challenges associated with transporting heavy and bulky steel goods. Whether it’s raw materials, finished products, or machinery, ABCC India Project Cargo has the capabilities and know-how to ensure the smooth and secure transportation of steel-related cargo.

Central to ABCC India Project Cargo’s success is its robust infrastructure tailored to meet the specific needs of the steel industry. The company boasts a comprehensive fleet of specialized vehicles, including flatbed trucks, trailers, and cranes, capable of handling various types of steel cargo. Additionally, its strategically located warehouses and storage facilities enable efficient inventory management and distribution, further enhancing the reliability and responsiveness of its services.

Safety is a top priority for ABCC India Project Cargo, and the company adheres to stringent safety protocols to protect both its personnel and the transported goods. By employing trained professionals and utilizing advanced safety equipment, ABCC India Project Cargo minimizes the risks associated with handling steel industry goods, ensuring secure transit from origin to destination. Furthermore, the company maintains a stellar safety record, instilling confidence and peace of mind in its clients.

ABCC India Project Cargo’s commitment to excellence extends beyond operational efficiency to encompass exceptional customer service. The company understands the importance of timely deliveries and strives to meet and exceed customer expectations at every step of the transportation process. Its dedicated team of logistics experts works closely with clients to develop customized solutions tailored to their specific requirements, fostering strong and enduring partnerships built on trust and reliability.

In addition to its operational prowess, ABCC India Project Cargo places a strong emphasis on compliance with regulatory standards and industry best practices. Whether navigating customs regulations or adhering to environmental guidelines, the company ensures full compliance throughout the transportation process, mitigating risks and minimizing disruptions for its clients.

Moreover, ABCC India Project Cargo offers competitive pricing without compromising on quality or service standards. By leveraging its extensive network, operational efficiency, and industry expertise, the company delivers cost-effective transportation solutions that provide tangible value to its clients in the steel industry.

In conclusion, ABCC India Project Cargo emerges as a trustworthy and dependable choice for steel industry goods transportation. With its wealth of experience, robust infrastructure, unwavering commitment to safety and customer satisfaction, and adherence to regulatory compliance, the company exemplifies excellence in the field of logistics. For businesses seeking reliable and efficient transportation solutions for their steel industry goods, ABCC India Project Cargo stands out as a partner of choice, capable of delivering results that exceed expectations.

Basic Raw Material Supplier in Steel Industries

| Raw Material Category | Examples of Suppliers (Type, Not Specific Companies) | Why Preferred |

|---|---|---|

| Iron Ore | Large Mining Companies, Captive Mines of Steel Producers | Rich iron ore reserves (National Mineral Development Corporation, Captive Mines of Tata Steel, SAIL etc.) |

| Coal | Coal India Limited (CIL), Captive Mines of Steel Producers | Reliable source of domestic coal (CIL), Reduced dependence on imports (Captive Mines) |

| Manganese Ore | Manganese Ore India Limited (MOIL), Private Miners | MOIL – Major supplier of manganese in India, Private miners can offer competitive pricing |

| Limestone | Cement Companies, Independent Limestone Quarries | Cement companies often have excess limestone, Independent quarries offer flexibility |

| Metallurgical Coke | Public Sector Undertakings (PSUs), Private Coke Oven Plants | PSUs – Reliable source (e.g., Coal India Byproducts), Private plants can offer competitive pricing |

| Fluxes (e.g., Dolomite) | Independent Miners and Processing Units | Widely available resource, Competitive pricing from independent suppliers |

| Company Name | Website | Why Considered Good Supplier |

|---|---|---|

| Coal India Limited (CIL) | https://www.coalindia.in/ | Largest coal producer in India, ensuring reliable supply of a crucial raw material. |

| National Mineral Development Corporation (NMDC) | https://www.nmdc.co.in/ | Public sector undertaking with large iron ore reserves, offering a stable source of high-quality iron ore. |

| Adani Enterprises Limited | https://www.adani.com/ | Diversified conglomerate with a presence in the mining sector, offering a potential one-stop shop for coal and other minerals. |

| Vedanta Limited | https://www.vedantaresources.com/ | Major player in the mining and metals sector, offering iron ore and other resources. |

| Tata Steel Minerals Limited | https://www.tatasteelcanada.com/ | Subsidiary of Tata Steel, focusing on securing raw materials for the steel industry. |

Steel Industry Contribution in Indian Economy

The Indian steel industry is a significant contributor to the Indian economy in several ways. Here’s a breakdown of its impact:

Economic Contribution:

GDP: The steel industry contributes approximately 2% to India’s Gross Domestic Product (GDP). This translates to a substantial amount considering the overall size of the Indian economy.

Employment: The industry directly employs around 6 lakh people and indirectly supports an estimated 20 lakh jobs across various sectors like mining, transportation, and construction. This generates income and boosts overall economic activity.

Infrastructure Development: Steel is a vital material for building infrastructure like bridges, roads, and buildings. A robust steel industry ensures the availability of this essential material for national development.

Manufacturing: Steel is a key input for many manufacturing sectors like automobiles, machinery, and appliances. A strong domestic steel industry reduces dependence on imports and supports growth in these allied sectors.

Strategic Importance:

Self-Reliance: India boasts the world’s fifth-largest reserves of iron ore, a crucial raw material for steel production. This resource endowment helps reduce dependence on imported steel and promotes self-reliance.

Foreign Exchange Earnings: India’s steel industry is not just import-substituting, it’s also a major exporter. Steel exports contribute foreign exchange earnings, which are valuable for the Indian economy.

Technological Advancement:

Innovation: Steel companies in India are increasingly investing in research and development to improve production processes and develop new steel grades. This fosters technological advancements and strengthens the industry’s competitive edge.

Challenges and Future Considerations:

Environmental Impact: Steel production can be energy-intensive and generate pollution. The industry needs to focus on adopting cleaner technologies and sustainable practices to minimize environmental impact.

Resource Depletion: While India has iron ore reserves, responsible mining practices and exploration of alternative resources are crucial for long-term sustainability.

Overall, the Indian steel industry plays a critical role in the country’s economic development. By addressing challenges and embracing sustainable practices, the industry can continue to be a powerful driver of growth and prosperity for India.

Transportation Industry Impact Steel Industry

The transportation industry and the steel industry have a mutually beneficial and interdependent relationship. Here’s a breakdown of how they impact each other:

Transportation Industry’s Impact on Steel Industry:

Demand for Steel: The transportation industry is a major consumer of steel. Steel is used extensively in the manufacturing of:

Vehicles (cars, trucks, buses, trains)

Ships and barges

Railway tracks and infrastructure

Containers for shipping goods

Transportation Efficiency: An efficient transportation network is crucial for the steel industry. This ensures:

Timely delivery of raw materials like iron ore and coal to steel mills.

Cost-effective transportation of finished steel products to customers across the country and for export.

Reliable movement of heavy machinery and equipment used in steel production.

Steel Industry’s Impact on Transportation Industry:

Stronger and Lighter Vehicles: Advancements in steel technology have led to the development of high-strength, lightweight steels. This allows for the creation of:

More fuel-efficient vehicles in the transportation sector.

Vehicles with improved durability and safety.

Improved Infrastructure: The steel industry supplies the steel needed to build and maintain transportation infrastructure like:

Bridges

Roads

Railways

Airports

Shipping ports

Durable Transportation Equipment: Steel is used to manufacture various components for the transportation industry, including:

Ship hulls and containers

Railway tracks and locomotive parts

Cranes and other heavy machinery used in transportation hubs

Challenges and Opportunities:

Logistics and Efficiency: Both industries strive for improved logistics and efficient transportation networks to reduce costs and emissions.

Sustainable Practices: There’s a growing focus on using recycled steel scrap and developing cleaner steel production methods to minimize environmental impact within both industries.

Overall, the transportation and steel industries are critical partners in enabling economic activity and infrastructure development. Advancements in one industry often lead to advancements in the other, creating a cycle of innovation and progress.

Worldwide Top Steel Companies

| Rank | Company Name | Headquarters | Country | Crude Steel Production (Million Tonnes) |

|---|---|---|---|---|

| 1 | China Baowu Group | Shanghai | China | 131.84 |

| 2 | ArcelorMittal | Luxembourg | Luxembourg | 79.3 |

| 3 | Ansteel Group | Anshan | China | 62.4 |

| 4 | Nippon Steel Corporation | Tokyo | Japan | 41.4 |

| 5 | Shagang Group | Jiangsu | China | 40.2 |

| 6 | HBIS Group | Tangshan | China | 40.1 |

| 7 | POSCO | Pohang | South Korea | 40.0 |

| 8 | Jianlong Group | Jiangsu | China | 39.2 |

| 9 | Shougang Group | Beijing | China | 37.0 |

| 10 | Tata Steel | Jamshedpur | India | 34.8 |

Where in India is the largest favorable market for Steel industries ?

| Region | Favorable Factors for Steel Industry |

|---|---|

| Western India (Maharashtra, Gujarat) | * Major Industrial Base (Automobiles, Construction) * Strategic Ports for Import/Export * Growing Automotive Industry |

| Northern India (Punjab, Haryana, Uttar Pradesh) | * Developed Infrastructure * Large Population (High Demand for Construction) * Established Steel Production Facilities |

| Southern India (Chennai, Bengaluru) (Emerging Market) | * Developing Industrial Hubs * Focus on Infrastructure Projects * Potential for Future Growth |

Dark Time of Steel Industries in India

While the Indian steel industry is a powerhouse today, it hasn’t always been smooth sailing. There haven’t been single “dark times” encompassing the entire industry, but there have been periods of challenges and stagnation. Here are a few points to consider:

Pre-Independence Era (1800s – 1947):

Limited Growth: The steel industry saw limited growth under British rule, primarily focused on serving colonial needs.

Technological Stagnation: Adoption of modern steel production methods was slow compared to other countries.

Early Public Sector Focus (1950s – 1980s):

While government investment in public sector steel plants laid a foundation, initial inefficiencies and bureaucratic hurdles hampered growth.

Limited Competition: The dominance of public sector companies without significant private participation might have stifled innovation to some extent.

Global Economic Slowdowns:

Periods of global economic recession can impact steel demand worldwide, affecting Indian producers as well.

Looking Forward:

The Indian steel industry has emerged from these challenges and is now a major global player.

However, there are still ongoing concerns like:

Resource Availability: Ensuring sustainable mining practices and exploring alternative resources for long-term steel production.

Environmental Impact: Minimizing pollution through cleaner technologies and responsible waste management.

Competition: Maintaining a competitive edge in the global market.

Overall, the Indian steel industry has a rich history with periods of both growth and challenges. Recognizing these past hurdles can help in understanding the industry’s current strengths and future opportunities.

Steel Industry: Pros and Cons

Here’s a chart outlining the pros and cons of the Steel Industry:

| Pros | Cons |

|---|---|

| High Strength and Durability: Steel is a strong and long-lasting material, ideal for construction, infrastructure, and various industrial applications. | Environmental Impact: Steel production can be energy-intensive and generate air and water pollution if not managed properly. |

| Versatility: Steel can be formed into various shapes and sizes, making it suitable for a wide range of applications. | Resource Depletion: Iron ore, a key raw material for steel, is a finite resource. Sustainable mining practices and exploration of alternatives are crucial. |

| Recyclability: Steel is one of the most recyclable materials, reducing reliance on virgin resources and minimizing waste. | High Initial Costs: Setting up and operating steel mills requires significant capital investment. |

| Boosts Infrastructure Development: Steel is vital for building bridges, roads, railways, and other essential infrastructure. | Safety Concerns: Accidents can occur during steel production and require proper safety measures to protect workers. |

| Economic Benefits: The steel industry creates jobs, generates revenue, and contributes to a nation’s GDP. | Global Competition: The steel industry faces competition from other countries, impacting prices and market share. |

| Innovation: The steel industry is constantly innovating to develop new, stronger, and lighter steel grades. |

Overall, the steel industry plays a significant role in the global economy and infrastructure development. However, addressing environmental concerns, resource sustainability, and safety protocols are crucial for its long-term viability.

Steel Industry in India: A Powerful Player with Room for Growth

The Indian steel industry is a significant force in the global market, boasting several strengths:

Strong Production Capacity: India ranks second in the world for crude steel production, showcasing its substantial capabilities.

Resource Richness: India has abundant iron ore reserves, a key raw material for steelmaking.

Government Support: Government initiatives promote industry growth and modernization.

Skilled Workforce: India has a large pool of skilled workers supporting the steel sector.

Focus on Innovation: Leading Indian steel companies are increasingly investing in research and development for better production methods and steel grades.

However, there are also challenges to address:

Environmental Impact: Minimizing pollution and adopting sustainable practices are crucial for long-term viability.

Resource Depletion: Responsible mining practices and exploration of alternative resources are essential for the future.

Infrastructure Bottlenecks: Efficient transportation networks are needed to ensure smooth raw material delivery and finished product movement.

Global Competition: The Indian steel industry needs to maintain its competitive edge in a globalized market.

Looking Ahead:

By addressing these challenges and embracing technological advancements, the Indian steel industry is well-positioned for continued growth. Here are some potential future directions:

Focus on Sustainability: Developing cleaner steel production technologies and utilizing recycled steel scrap are crucial.

Strategic Partnerships: Collaboration with foreign companies can bring in advanced technologies and expertise.

Market Diversification: Exploring new export markets and catering to niche steel segments can further strengthen the industry.

Overall, the Indian steel industry is a powerful contributor to the nation’s economy and infrastructure development. By overcoming challenges and embracing innovation, this vital sector has the potential to become an even more sustainable and globally influential force in the years to come.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

Peb Enginieering Association :- www.pessi.in

Indian Steel Association :- www.indsteel.org

Builders Association of India :- www.baionline.in

Indian Stainless Steel Development Association (ISSDA) :- www.stainlessindia.org

Cement Manufacturers Association (CMA) :- www.cmaindia.org

NOTE :- From our point of view, the biggest problem today is that due to mistrust, disagreement, insecurity, today the price of our business and daily essential commodities and raw materials is increasing infinitely unnecessary.We have a small effort which is expected that every good buyer should get a good seller without a middleman and a good seller gets a good buyer.We always provide advanced information on our behalf to our customers. If you are interested in public interest by the presentation and renewal of your business, then share with us by people what revolutionary changes you have made to your business that have benefited the people.So that our good business community and you also benefit forever. And people should benefit so that a good business environment is created.

Advantage Our Pro Membership :-We provide advanced support to our pro membership clients in Transportation, Logistics, Warehousing, Finance etc….

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

Indian Steel Association

Indian Stainless Steel Development Association (ISSDA)

Public frequently asked questions (FAQs) :-

What Steel is made of?

Steel is an alloy of iron and carbon containing less than 2% carbon and 1% manganese and small amounts of silicon, phosphorus, sulphur and oxygen. Steel is the world’s most important engineering and construction material.

Who started the steel industry?

In the early 1870s, Carnegie co-founded his first steel company, near Pittsburgh.

What industry uses the most steel?

Construction industry is the largest consumer, accounting for approximately 50% of total world steel consumption. Transport sector (cars, trucks, aviation, shipbuilding, and rail) is the second. The machinery industry and metal products industry each consume around 14% of the world’s steel.

steel stronger than pure iron?

By weight, steel contains about 2.14% carbon. Although that’s a relatively small amount of carbon, it results in significant physical changes. Steel, for example, is both harder and stronger than pure iron. And unlike iron, steel isn’t an essential mineral.

Steel is stronger than iron, because an excess of carbon in iron and pig iron makes it weaker than steel. The quantity of carbon is very tightly controlled in steel. It is about 0.8 percent carbon, just the right amount to give it intramolecular strength.

Why is steel so heavy?

As mentioned, steel gets its weight from the high concentration of carbon. The more carbon an alloy contains, the heavier it will be. The primary benefit to the weight of steel is that it is incredibly durable. Its strength means that it is unlikely to bend, warp, or deform underweight, heat, or force.

Steel is man made?

Today, steel is one of the most common man made materials in the world, with more than 1.6 billion tons produced annually.

What is the hardest steel?

Chromium is the hardest metal known to man. While you may not have heard of chromium, more than likely you’ve heard of stainless steel. Chromium is the key ingredient in stainless steel, thus it is used in a variety of settings.

What are the different types and grades of steel?

Steel is graded as a way of classification and is often categorized into four groups—Carbon, Alloy, Stainless, and Tool.

What is the most common type of steel?

Low carbon steel (or “mild carbon steel” or “plain carbon steel”) refers to carbon steels that have up to 0.30% carbon content. This is, by far, the most common type of steel on the metals market.

What is steel formula?

Steel is an alloy. It mixture of iron and carbon fused together with one or more other metals or nonmetals. The chemical formula is Fe.

Which steel company is best?

TATA Steel

Which is largest steel plant in India?

Bhilai Steel Plant

Who are the top producers of steel in the world?

ArcelorMittal , China Baowu Steel Group,Nippon Steel,

Who makes the best stainless steel in the world?

Acerinox is the world’s largest producer of stainless steel. It is formed by three fully integrated flat products production facilities (Acerinox Europa in Spain, North American Stainless in the USA and Columbus Stainless in South Africa)

Which is the newest steel plant in India?

Dolvi Steel Plant , A new steel plant is fast coming up at Dolvi in Ratnagiri district in Maharashtra.

Which company TMT bar is best in India?

Top best TMT bars brand in India are – 1) Tata tmt bar grade Fe500, 2) Tata tiscon SD TMT bar, 3) Jindal Panther TMT bar, 4) Sail TMT bar, 5) Kamdhenu TMT bar, 6) SAIL and ViZag CRM TMT bar, 7) Tata TMT bar, 8) SRMB steel tmt bar, 9) JSW steel tmt, 10) Shyam Steel tmt bar, 11) Madhuban any local suplier

Who makes the world’s maximum steel?

China produces the most steel in the world every year, producing more than half of the world’s steel.

Which city is famous for iron and steel?

Jamshedpur is famous for iron and steel industry. It is located in the State of Jharkhand in India .

Which is the first steel plant in India?

Rourkela Steel Plant (RSP), the first integrated steel plant in the public sector in India, was set up with German collaboration with an installed capacity of 1 million tonnes.

Steel stronger than stainless steel?

Strength of steel and stainless steel: Steel is slightly stronger than stainless steel as it has lower carbon content. Also, it is weaker than steel in terms of hardness.

Why is Chinese steel so cheap?

Companies in China are producing steel at a faster rate, flooding the market and dropping prices. It is produced at a rapid rate and it is not held up to the same quality standards as American steel.

Where is the largest steel mill in the world?

Today, the world’s largest steel mill is in Gwangyang, South Korea.

Which state is largest producer of steel in India?

Maharashtra and Tamil Nadu are largest steel using states, both auto hubs. Steel producing states in the east have not seen development of own steel markets.

What is full form of TMT steel?

Thermo mechanical treatment (TMT)

What do you mean by steel industry?

the business of processing iron ore into steel, which in its simplest form is an iron-carbon alloy, and in some cases, turning that metal into partially finished products or recycling scrap metal into steel. The steel industry grew out of the need for stronger and more easily produced metals.

What is the future of steel industry in India?

As per Indian Steel Association (ISA), steel demand will grow by 7.2% in 2019-20 and 2020-21. Huge scope for growth is offered by India’s comparatively low per capita steel consumption and the expected rise in consumption due to increased infrastructure construction and the thriving automobile and railways sectors.

Who invented TMT bars?

Prove that you are a good reader by telling us the answer.