Industry Overview

What is Cement ?

Cement is a fine, powdery substance that acts as a binder. When mixed with water, it sets and hardens, adhering to other materials and binding them together. It is seldom used on its own, but rather as a key ingredient in concrete and mortar.

Cement is most commonly made from limestone, clay, and other materials that are ground into a fine powder. The powder is then heated to a high temperature in a kiln, which causes a chemical reaction that changes the composition of the materials. The resulting product is clinker, which is then ground into a fine powder again to create cement.

There are many different types of cement, each with its own unique properties. The most common type of cement is Portland cement, which is used in a wide variety of applications, including the construction of buildings, bridges, and sidewalks. Other types of cement include masonry cement, which is used for brick and block work, and sulfate-resistant cement, which is used in environments where there is a high risk of sulfate attack.

Who When and Why Invented Cement ?

While there were earlier forerunners, the invention of Portland cement, the most common type today, is credited to Joseph Aspdin in 1824. He was a British bricklayer who was looking for a stronger alternative to existing materials.

Aspdin’s innovation involved heating a mixture of crushed limestone and clay in his kiln. The resulting product, finely ground, resembled a type of building stone called Portland stone, hence the name “Portland cement”.

It’s important to note that this early version may not have been exactly the same as modern Portland cement. Further refinements came later in the 19th century from others like Isaac Charles Johnson.

In this article, we see the top 10 Best Trustable and famous cement companies in India and its contribution to the growth and GDP of the Country.

Short Introduction :–

India ranks in the second position in the manufacturer of Cement after China with a capacity of 151.2 Million Tones. The government of India provides the best support to the cement industry by providing various infrastructure projects, road networks, and housing facilities. The consumers of cement are 13% for infrastructure, 11% for commercial construction, and 9% for industrial construction. Thereby the cement Industry provides support to the immense growth of life India. We can see about the best companies in India with their features and services region wise in the upcoming paragraphs.

Related :-

Warehouse and Warehousing Storage

Types of Warehouse

Warehouse Management WMS Services

Top Cement Companies India:-

On comparing, all the cement companies in India Ultra Tech Cement and Shree Cement Limited are considered to be the top companies in India. We can see the features of Company in detail.

Ultra Tech Cement Limited :-

Ultra Tech is considered to be the largest cement industry in India. And it is one of the top companies in the world. The various characteristics of the company are. It has branches in five countries.

The various operational plants managed by this industry are

- Integrated plants:11.

- White cement plant: 1.

- Clinkerisation plant: 1.

- Grinding units: 15.

- Ready mix concrete plant: 101

Two rails and three coastal terminals. It has the largest clinker exporter in India. It has its headquarters in Mumbai and has established in 1987.

Shree Cement Limited :-

This cement industry is considered to be the most trusted industry in India. The specialities of this industry are.It was doing its manufacturing process in six states of Northern and Eastern parts of India.It is considered to be one of the best Trailer transportation in cement Industry.This is one among the top companies in India as it is environment-friendly and provides the best quality cement. It has its headquarters in Bangor Nagar, Ajmer, and Rajasthan And this company was started in the year 1970.These are the special features of the top two cement manufacturing and supplying industries around all states of India. Most of the peoples and industrialist prefer to this industry’s cement products due to its valuable service and affordable cost.

Top Cement Companies in North East India Region:–

Here are some of the major cement companies in North East India:

Hills Cement Company Limited (Mynkree, Meghalaya): A leading cement producer in the region known for its high-quality product.

Amrit Cement Ltd. (Umlaper, Lad Rymbai, Meghalaya): Another major player in the North East Indian cement market.

Topcem Cement (a brand of Meghalaya Cements Ltd.): Popular for its cement designed for the tough weather conditions of the North East, including seismic activity.

Dalmia Cement (Bharat) Ltd. (Assam): A prominent name in the Indian cement industry with a presence in the North East.

Surya Gold Cement (Assam): A popular brand in Assam known for its Ordinary Portland Cement (OPC) and Portland Pozzolana Cement (PPC)

Top Cement Companies in Northern India Region:–

The top cement companies in North India are major players in the national market. Here are some of the leading ones:

- UltraTech Cement Ltd. – The largest manufacturer of white and grey cement in India, UltraTech is a household name. They are known for their extensive reach and commitment to high-quality products.

- Ambuja Cements Ltd. – A strong contender, Ambuja Cements comes in second with a national reputation for its reliable cement. They are known for their innovative research and development in the field.

- Shree Cement Ltd. – A major name in the industry, Shree Cement is a prominent producer known for its wide network and focus on customer satisfaction.

- ACC Limited – A well-established brand, ACC Limited (formerly The Associated Cement Companies Limited) is a reliable name in the cement industry. They are known for their high-quality standards and commitment to sustainability.

- Dalmia Cement (Bharat) Ltd. – A prominent name not just in North India but across the country, Dalmia Cement is known for its superfast setting cement and other building solutions.

These are just a few of the top players in North India’s cement industry. The choice of company may depend on various factors like specific product requirements, project location, and budget.

Top two Cement companies in Western India Region:–

The top two companies in the western region of India are described in the below-given paragraph.

JK. Cement Ltd :-

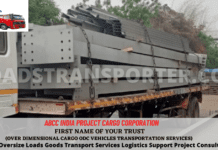

J.K. cement is the best manufacturers and suppliers of various cement products based on the needs. This company was started by Lala Kamlapat Singhania in 1975. And it has its headquarters in the Kanpur. The characteristics of the company are.It is considered to be the second-best manufacturer and supplier of white cement and wall putty in all the states of India.As the annual production of the company is 600,000 tons capacity of cement to 700,000 tons capacity in India. It is considered to be the ODC Cargo Transportation cement industry in India.It was awarded productivity and excellence award by the Rajasthan State Productivity Council continuously for four years.

Ambuja Cement Ltd :-

This Ambuja cement is considered to be one of the popular company in the western part of India. In olden days it was named as Gujarat Ambuja Cements Limited. As it is the best producer of the cement products, it has become the part of the global conglomerate Lafarge Holcim. The features of the company are This company was started in the year 1983.It has headquarters in Mumbai.The annual production of this company is 29.65 tons capacity of cement and the cement products.It has totally five cement manufacturing plant and eight cement grinding plants in various parts of the country.

Top two Cement companies in Southern India Region:–

The best cement manufacturing industry in the southern regions of India are Zuari cements Limited and India Cements. In this topic, we can see the features of these cement companies in detail.

Zuari cements Limited :-

The Zuari cement is the part of the Heidelberg Cement group, which is considered to be the global Construction material major. The various best features of the Zuari cement industry are listed below.

This company is ranked in the first position for aggregates, the second position in cement manufacturing, and third position in the ready-mix concrete.

- The total cement manufactured by this company is 7.1 million tons of capacity in India.

- There are two integrated manufacturing units in Sitapuram and Yerraguntla.

- And there are two grinding units in Chennai and Solapur.

- It has its cement terminal in Kochi.

India cements :-

This is one of the best cement manufacturing Company among the top companies in India. It was started in the year 1946 by S.N.N. Sankaralinga Iyer.

- The first plant of the India cement was started at Thalaiyuthu in Tamil Nadu at 1949.

- Presently, it consists of seven integrated plants in Tamil Nadu for manufacturing cement.

- The total capacity of cement manufactured by this company for one year is 15.5 million tonnes.

- The different branded companies owned by the India cement are Sankar, Coromandel, and Raasi gold.

- This company has its headquarters in Chennai and it is a public sector company in India.

These are the features and specifications of the best companies in the southern part of India. The importance of transportation in cement industry in India has contributed so much to the development of the economy.

Related :-

Trucks Truckers and Trucking

Goods Transportation Problems

Logistics Overview

Factories survey

Conclusion :–

The cement industry plays an important role in the growth of India GDP. The top cement manufacturing companies in India provides millions of employment for the young generation people. Hence the needs of millions of job seekers are satisfied through these cement companies. There is a significant growth in the cement industry which is mainly due the real estate, construction, and infrastructure industries of India. Presently, India facts say that the industry in India is growing 5-6% per year. Therefore the production of the cement and cement products are also increased which promotes the organization growth. I hope that after reading this article, you are familiar with the various cement industries in India and its importance for the growth of the economic background of the country.

History of Cement Industry in India

The Indian cement industry boasts a rich history that can be traced back to the early 1900s, here’s a breakdown of its key milestones:

Early Beginnings (Pre-1914):

There are traces of a small cement factory established in Madras (Chennai) by South India Industrial Ltd. around 1904, indicating early interest in cement production.

Birth of the Industry (1914):

The year 1914 marks a turning point with the setting up of the Indian Cement Company Limited in Porbandar, Gujarat. This is considered the official birth of the organized cement industry in India.

Initial Challenges (1914-1930s):

Though Indian companies started production, they faced stiff competition from cheaper imports of cement.

To address this, the government implemented policies like quotas and the formation of the Cement Marketing Company of India (CMCI) in 1930.

Consolidation and Growth (1930s-1980s):

A significant event occurred in 1936 with the formation of the Associated Cement Companies Ltd. (ACC) by merging various cement companies.

The industry received importance in India’s Five-Year Plans, with a focus on increasing production capacity.

The Cement Manufacturers’ Association (1925) and the Concrete Association of India (1927) were established to support industry growth.

Decontrol and Boom (1980s-Present):

A turning point came with the partial decontrol of cement in the 1980s, followed by complete decontrol in 1989. This led to increased investment, modernization, and a surge in production capacity.

Today, India is the second-largest cement producer globally, only behind China.

Additional Points:

The industry has continuously evolved, adopting new technologies and environment-friendly practices.

Several major Indian and multinational companies are major players in the market today.

I hope this provides a good overview of the history of the cement industry in India!

Fact About Indian Cement Industry

The Indian cement industry is one of the largest in the world, both in terms of production capacity and consumption. Here are some key facts about the Indian cement industry:

- Production Capacity: India is the second-largest cement producer globally, just behind China. The country has a significant installed capacity for cement production, with numerous cement plants spread across the country.

- Growing Demand: Cement demand in India is primarily driven by the construction sector, which includes infrastructure projects, residential buildings, and commercial construction. The growing urbanization and infrastructure development in the country continue to fuel the demand for cement.

- Market Competition: The Indian cement industry is highly competitive, with several major players dominating the market. Some of the prominent cement companies in India include UltraTech Cement, ACC Limited, Ambuja Cements, Shree Cement, and Ramco Cements, among others.

- Technological Advancements: Indian cement companies are increasingly adopting advanced technologies and practices to improve efficiency, reduce environmental impact, and enhance product quality. This includes the use of alternative fuels, waste heat recovery systems, and advanced automation in manufacturing processes.

- Environmental Concerns: The cement industry is a significant contributor to carbon emissions and other environmental impacts. In recent years, there has been a growing emphasis on sustainability and environmental conservation in the Indian cement sector. Companies are investing in cleaner technologies and exploring alternative materials to reduce their carbon footprint.

- Government Initiatives: The Indian government has been promoting infrastructure development and affordable housing through various initiatives such as “Make in India,” “Smart Cities Mission,” and “Housing for All.” These initiatives provide a significant boost to the cement industry by increasing demand for construction materials.

- Exports: While the primary focus of the Indian cement industry is catering to domestic demand, some companies also export cement to neighboring countries and other international markets. However, exports constitute a relatively smaller portion of overall production compared to domestic consumption.

- Challenges: Despite its growth potential, the Indian cement industry faces several challenges, including fluctuating raw material prices, regulatory hurdles, land acquisition issues, and infrastructural constraints. Addressing these challenges requires concerted efforts from both the government and industry stakeholders.

Overall, the Indian cement industry plays a crucial role in the country’s economic development and infrastructure growth, and it continues to evolve to meet the changing demands and challenges of the market.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

Peb Enginieering Association :- www.pessi.in

Indian Steel Association :- www.indsteel.org

Builders Association of India :- www.baionline.in

Indian Stainless Steel Development Association (ISSDA) :- www.stainlessindia.org

Cement Manufacturers Association (CMA) :- www.cmaindia.org

NOTE :- From our point of view, the biggest problem today is that due to mistrust, disagreement, insecurity, today the price of our business and daily essential commodities and raw materials is increasing infinitely unnecessary.We have a small effort which is expected that every good buyer should get a good seller without a middleman and a good seller gets a good buyer.We always provide advanced information on our behalf to our customers. If you are interested in public interest by the presentation and renewal of your business, then share with us by people what revolutionary changes you have made to your business that have benefited the people.So that our good business community and you also benefit forever. And people should benefit so that a good business environment is created.

Advantage Our Pro Membership :-We provide advanced support to our pro membership clients in Transportation, Logistics, Warehousing, Finance etc….

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

Public frequently asked questions (FAQs) :-

What is cement ?

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

Who is father of cement?

Joseph Aspdin , his father, is proven to have patented the method of cement manufacture in 1824 which is how cement continues to be made to this day, albeit with technological advances

Which is stronger cement or concrete?

Cement is not stronger than concrete. On its own, in fact, cement is prone to cracking. When combined with aggregate materials and water and allowed to harden, however, cement now concrete is extraordinarily strong.

What is the difference between cement and concrete?

Although the terms cement and concrete often are used interchangeably, cement is actually an ingredient of concrete. Concrete is a mixture of aggregates and paste. The aggregates are sand and gravel or crushed stone; the paste is water and portland cement.

What is cement formula?

Cement is a mixture of different compounds. It consists of Calcium oxide(CaO),Silicon dioxide(SiO2),Aluminum oxide(Al2O3),Iron oxide(Fe2O3),Water(H2O),Sulfate(SO3) and do not have any specific formula.

What is natural cement?

Natural cement is hydraulic cement made from limestone that has a high clay content (argillaceous limestone). It is different from building lime, which is made from limestone with a lower clay content, in that lime is not hydraulic (does not set under water).

Cement is man made?

cement isn’t some sort of naturally occurring organic material – it’s manufactured through the chemical combination of 8 main ingredients during the cement production process. These ingredients are generally extracted from limestone, clay, marl, shale, chalk, sand, bauxite, and iron ore.

What is the use of cement?

Cement is mainly used as a binder in concrete, which is a basic material for all types of construction, including housing, roads, schools, hospitals, dams and ports, as well as for decorative applications (for patios, floors, staircases, driveways, pool decks) and items like tables, sculptures or bookcases.

What are the types of cement?

Different types of cement used in construction and civil engineering.

Portland Cement

White Cement

Water Repellent Cement

Sulfate Resistant Cement

Rapid Hardening Cement

Expansive Cement

Air Entraining Cement

What is the most common type of cement?

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout.

Cement is stronger without sand?

In order to produce a strong, resilient concrete mix, you need to get the ratio of aggregate to sand to cement right. So if you don’t mix sand to the cement, cement will set of course but will give a lot of shrinkage crack and may not give the desired bonding.

Cement easy to use with work ?

Concrete is easy to work with, versatile, durable, and economical. By observing a few basic precautions, it is also safe-one of the safest building materials known. Over the years, relatively few people involved in mixing, handling, and finishing concrete have experienced injury.

What are ingredients of cement?

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

What was used before cement?

Early cementicious composite materials typically included mortar-crushed, burned limestone, sand and water, which was used for building with stone, as opposed to casting the material in a mold, which is essentially how modern concrete is used, with the mold being the concrete forms.

What is the cost of 1 bag cement?

Prices ranges between 300 to 400 (Handling and Transportation Cost Extra ) depending upon type of cement (OPC/PPC) and quantity required.

What is the cement industry?

The cement industry is the building block of the nation’s construction industry. Few construction projects can take place without utilizing cement somewhere in the design.

Which is the No 1 cement in India?

Ultratech Cement

Where is cement industry in India?

total 210 large cement plants in India, 77 are in the states of Andhra Pradesh, Rajasthan, and Tamil Nadu. Sale of cement in India stood at Rs 63,771 crore (US$ 9.05 billion) in FY20. India’s export of cement, clinker and asbestos increased at a CAGR of 6.44% between FY16-FY19.

Which city is famous for cement industry?

The cement industries which use oceanic shells as a raw material has been set up at Dwarka (Gujarat), Thiruananthapuram (Kerala), and Chennai (Tamil Nadu). India is one of the largest cement producers in the world after China.

What are the problems of cement industry?

Cement production releases 5–6% of all carbon dioxide generated by human activities, accounting for about 4% of global warming. It can release huge amounts of persistent organic pollutants, such as dioxins and heavy metals and particles. Energy consumption is also considerable.

Which city is famous for cement industry?

The cement industries which use oceanic shells as a raw material has been set up at Dwarka (Gujarat), Thiruananthapuram (Kerala), and Chennai (Tamil Nadu). India is one of the largest cement producers in the world after China.

Which city is famous for cement industry?

The cement industries which use oceanic shells as a raw material has been set up at Dwarka (Gujarat), Thiruananthapuram (Kerala), and Chennai (Tamil Nadu). India is one of the largest cement producers in the world after China.

What are the problems of cement industry?

The cement industries which use oceanic shells as a raw material has been set up at Dwarka (Gujarat), Thiruananthapuram (Kerala), and Chennai (Tamil Nadu). India is one of the largest cement producers in the world after China.

Which country is largest producer of cement?

China produces the most cement globally by a large margin, at an estimated 2.2 billion metric tons in 2020, followed by India at 340 million metric tons in the same year. China currently produces over half of the world’s cement.

Which is the world’s best cement?

CNBM [China National Building Material Ltd] China National Building Material Co. Ltd.

Who is the largest producer of cement in India?

Andhra Pradesh is the largest cement producer. Production of Andhra Pradesh of about 37.52 million tons in the period 2008−2009 , which is about 17.12% of all India production.

Which is the biggest cement plant in India?

The Wadi cement plant of ACC Limited, in India’s southern state of Karnataka, now enjoys the distinction of being the world’s largest cement plant.

Why is the cement industry important?

Cement is required by every industry cement is an important part of industrial infrastructure. It provides direct and indirect employment to a large number of persons and contributes a major part to Gross Domestic Product (GDP). Cement is a key infrastructure industry.

Cement company contribution Indian GDP ?

Ratio of profits from the cement sector to India’s GDP stood at 0.06 %