Manufacturing creates well and handles the machine with customer expectations or specifications. In addition, the step by step process with the division of labor in a large scales production. The Manufacturing Definition is the best process and along with producing a large number of business goods and more effect of industry employs human-machine setup with division of labor. However, it is one of the best process and including the raw materials of finished the lots of products with meet your customer requirements. you can find out to converting the parts of raw materials to finished the products. On another hand, you have converted and finished products is a manufacturer to use the terms of the person which similar to term of person to maintain the own factory executives these locations products you use every day manufacturing business. Moreover, There are possible to assemble the best part of the manufacturing business which tries to frame of most likely produced by this type of business.

The best manufacturing process example to uses the components and part of raw materials to makes to finished goods sold them directly to consumers or to other manufacturing businesses . However, you make sure about the different product and also normal machines, computers, robots, humans that all work in a particular manner to create a product. In the main factor, the manufacturing plans are used to the assembly line as well as the product of together quicker with less manual labor. However, you can find out the best industries refer to the manufacturing process as fabrication. The large amount of process which main parts of required the complicated and need to create the finished product. Many people want to businesses and manufacturing the legal regulations environmental laws to deal with many resources.

The Factory Operates Types Of Manufacturing Production:-

Recently, the manufacturing the simple business process to raw material or component parts manufacture a finished product to manufacturer needs to produce to supply the market .

Make To Stock:-

The factory produces goods to stores the predicting with the market for their the manufacturer will plan production activity in advance. it also produces the best needs to surplus at a loss and in producing too little market and not sell enough to cover costs

Make To Order :-

Many professional team experts offer the best manufacturing process of order stocks. It is easy to handle and control the need to rely on market place. Huge people should be waiting time too long though and the manufacturer needs with the high stream to keep the factory in production.

Make To Assemble:-

In needed, the factory produces the components of parts to anticipation orders for assembly. The ready to the fulfilment of customer orders with materialise producer will have a stock of unwanted parts .

Recommended :-

Advantages of road transport :- Please Click

Disadvantages of road transport :- Please Click

Oversized Load Transportation Problems :- Please Click

Keeping Risks with Under Control is Key:–

Manufacturing the three types of problems you can supply the much flood to causing the drop in price and drop in profits to customer drop in sales for the manufacturer. There are possible to quality control the big factor to successful manufacturing. You can find out the keeps to close the eye on quality to successful -term consequences may be serious. The high qualities of the manufacturing sector any types of the manufacturing process.

Manufacturing technology:-

Manufacturing technology provides the best tools are enabling to the production of all manufactured goods and needs. In the main factor, you can find out the best industry magnify the effort of individual workers to the industrial nation the power to turn raw materials at affordable and quality goods. There are possible to modern lives to manufacturing technology is very important and different types of machines are required to manufacture finished products. You can handle the tools of machines and versatile and complicated computerized in the CNC machines. In the main factor, it also involves lots of techniques and also details with casting, forging, soldering, brazing, alloying, welding and etc. Each and every technique to their own advantages and limitations specialized field of knowledge in their own right

Use of Metals And Materials:–

The best related part of strict with the better of manufacturing process technology. In addition, the complete source of materials is done by the use of metals and materials of various products such as semiconductors and alloys. Most importantly, you have to use of technology cannot be underestimated at any cost. There are possible to deals with the property of materials and under the different circumstances and environments in the very useful to materials to manufacture any sort of finished products using them. you want to specialize in the area of manufacturing technology and different types of many services and also includes the various techniques many of preceding sections for government coordination. Mainly focus on starting with the different machines to learning the basics of machine workshop including simple procedures such as filing, drilling, boring, honing, etc. Moreover, the more complicated to use heavy and versatile machine tools.

Advancement of Science and Technology:–

Each and every manufacturing process reaches the development of more frontiers and specialized needs. In addition, the steel and many times lighter than combined with other branches to computing the branch of mechanical engineering is certainly coming future. It also provides the best tools and economy and a rising standard of living. You have to consider the modern communications, affordable agricultural product and space to everyday conveniences of related equipment to their accessories to machine power driven manufacturing machinery. The particular operations produce durable goods or components and also assembly and test systems to create a final product or sub assembly.

Effective Manufacturing Process:–

What is manufacturing process? The complex of activity and the number of expertise tools to equipment numerous levels of automation computers, robots, and other equipment. You can understand the basis from the lots of methods to needed to placed properly for maximum layouts and set of complete solutions. Moreover, the effective industry process within a properly planned manufacturing firm to manufacturers or manufacturers workshop technology and highly troublesome for claim competence over it. Moreover, the large number of aspects to procedures for providing to working them different engineering materials such as accessories, manufacturing processes, basic concepts of machine instruments, tools, etc. Otherwise, the large number of testing the instruments and calibrating or inspecting with units of checking materials or products. Mainly focus on the various production shops in a commercial environment. It also used to different hand tools to support the machinery and diverse methods of production shaping the existing raw materials with the same manufacturing processes that are worth reading .

Types of Manufacturing Processes:–

Machining:-

Tools used for machining is immobile driven the units of form or shape solid specifically metals.The Traditional chip-making tools from the work-piece by trimming away the unwanted part of accessible chips to implement the several shaping processes and elongating. The best materials created to meet the requirements of modern technology

Joining:-

Each and every approach of particular design needs with a certain purpose of particular to fastener selection apply own specifications. The highly standard fastening the method welding may cut down the weight of assemblies. Moreover, the intended for the approaches would differ tremendously. It is one of the best processes to consider the features such as load factors, operating surroundings, assembly effectiveness and best materials should select. The laws of effective approach and also require marketing part in manufacturing industry overlapping materials, and so it removes to fastening methods. Moreover, you also fastening methods purchased and stored in stock to relate the extra parts to angles mounted between parts.

Forming:-

The Forming approaches to create the metallic components by deforming to removing, cutting, shredding at any part of the spinning, drawing, stretching in the important metal forming process in manufacturing. Of course, the metal press to punching tools is implemented for manufacturing the best process. You have to personalize the manufacturing the different components of simply changing the dies.

Casting :-

Casting is one of the manufacturing processes to solid and dissolved the liquid with heated to the appropriate temperature to change the chemical formula. You can find out the mold or cavity complex or simple shapes can be crafted from any kind of mental capability to be melted with working the challenge and improved the pleasing look can be developed.

Recommended :-

Transport Department :- Please Click

History of Transportation :- Please Click

importance of transport system :- Please Click

Manufacturing Defect Process:–

The manufacturing defect process to deviation from design and more specifications during production resulting in the product defect to short term and long term of solutions. The fabrication of product which develops to faulty medical devices and you can handle the best improperly manufactured and strays from the intended design. Mainly focused on the bottle of prescription medication that worker or improperly maintained processing facility. However, the filter to the premature result of substandard manufacturing with the manufacturing of the main product is considered a product manufacturing defect. Moreover, you can consider the types of cause to injuries to their consumers and make to defects their makers can be found liable in a court .

Manufacturing Defect Lawsuits:-

The better defect law of process and also protects the injured by a company’s defective products. However, the recent manufacturing sector condition with consumers injured by a company’s defective products. It also able to allows the plaintiffs to file a manufacturing defect lawsuit to enforce their rights and recover damages for their injuries. The best feature of important role in making sure that companies sell products across the world. Moreover, the best manufacturers can get their products to that corners are cut and consumers pay.

For instance, the Manufacturing defect should prove that legal procedure:-

- Occur the injured

- The manufacturing the best product with defect or defects

- It is more responsible for defects to great part process

- importance of the manufacturing industry

The importance of manufacturing modernizing agriculture treats tools and machines used in cultivation. You can find out the best-reduced employment pressure on agriculture. Then, you need to foreign exchange and more than expandable for foreign exchange and commerce. Moreover, the manufacturing industries developed in unemployment and poverty. There are possible to help to growth and boom in economy.

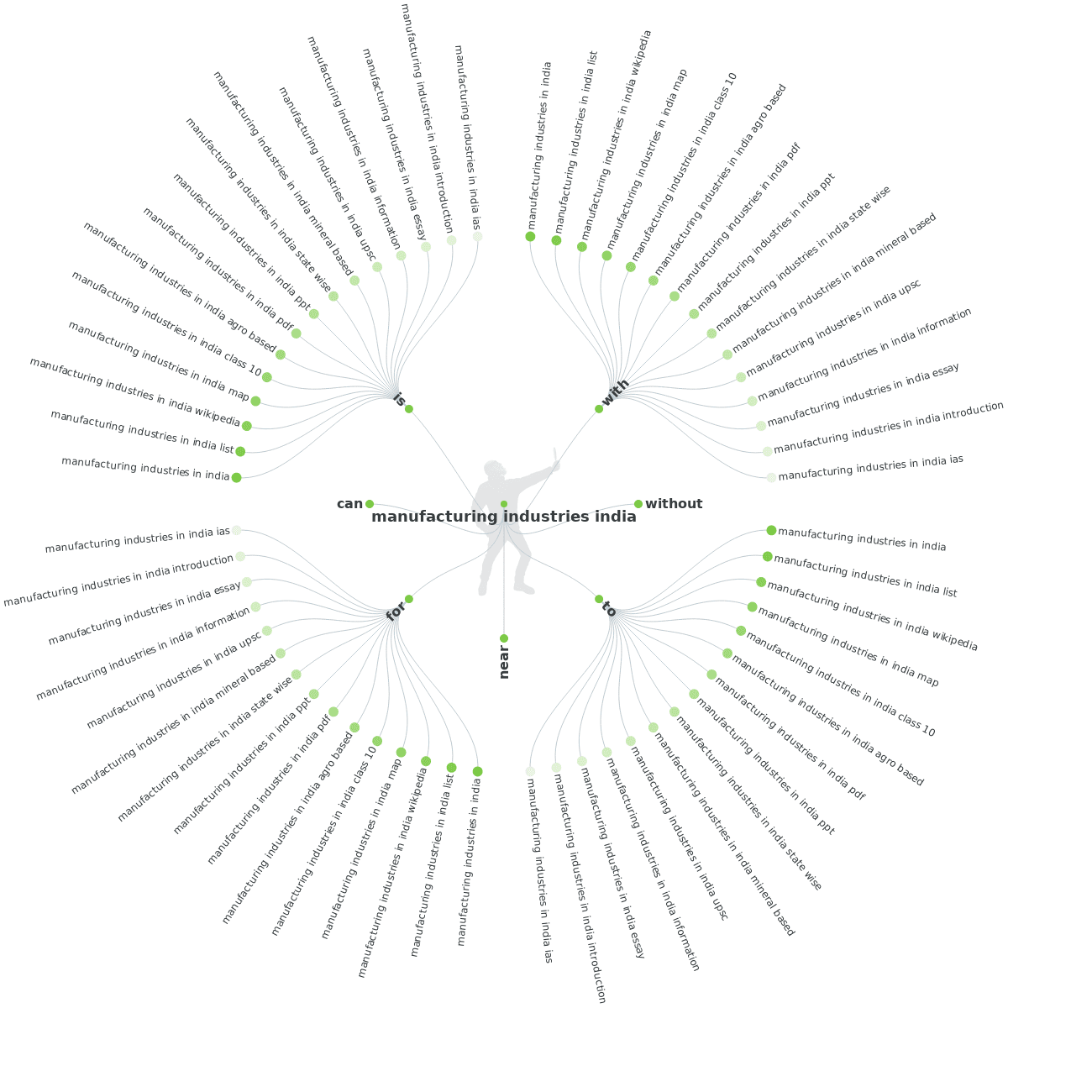

Digital Revolution Manufacturer In India :-

The future landscape of transformed by digital technologies with the different things to productivity gains are being realized through the cost of developments the quantum leap in performance and investment of proper traditional manufacturing back to the top of the competition. Moreover, you can find out the future of manufacturer in India left out of the ongoing digital revolution. Of course, you can achieve the target for the global manufacturing hub. A large number of process and growing to the choice of research and development centers and start-up base and a government focus on making the nation an easy place to do business. You can handle the best factory allows to industrial activities rather those of cultivating the land. Moreover, the industrial activities of process are very effective and even the productive. The best deal with the lots of years and manufacturing the sectors to entire gross domestic Product.

The catalyst effects on productivity to leading to key structural shifts with global manufacturing. However, it is very competitiveness of manufacturing are fundamentally localized manufacturing close to end-consumers with more existing low-cost labor arbitrage based with the profit drivers for manufacturers. However, the rapid growth of exchange of products in the supply chains to participate for economy skills to the most critical factor of production and driver of competitiveness. The small and medium of manufacturing with small-scale localized to more reliable and get growth of manufacturing with complete solutions to digital platforms without creating their own supply chains. Mainly focus on the best significant share of embedded with the physical infrastructure large-scale investments to the ecosystem are needed to develop the requisite skill gaps and ensuring the millions entering job markets. Effective solutions of state governments and reach your needs and manufacturing revolution and reaping benefits of enhanced competitiveness.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

Public frequently asked questions (FAQs) :-