What is Processed Food

Processed food is any food that has been altered from its natural state. This can include a wide variety of changes, from simply washing and chopping fruits and vegetables to more complex processes like canning, freezing, fermentation, pasteurization, and packaging .

Here are some of the common ways that foods are processed:

Washing and chopping: This is a simple form of processing that helps to prepare fruits and vegetables for consumption.

Cooking: Cooking can change the texture, flavor, and nutritional content of foods. For example, cooking can make some foods easier to digest and absorb nutrients.

Freezing: Freezing is a common way to preserve food. It slows down the growth of bacteria and other microorganisms that can cause spoilage.

Canning: Canning is a process of sealing food in a container and then heating it to a high temperature. This process kills bacteria and other microorganisms that can cause spoilage.

Fermentation: Fermentation is a process in which microorganisms break down carbohydrates into alcohol or lactic acid. This process is used to produce a variety of foods and beverages, such as yogurt, cheese, beer, and wine.

Pasteurization: Pasteurization is a process of heating a liquid food to a specific temperature for a specific amount of time. This process kills harmful bacteria that can cause foodborne illness.

Adding ingredients: Some processed foods have ingredients added to them, such as salt, sugar, fat, flavorings, colors, and preservatives. These ingredients can be added to improve the taste, texture, shelf life, or appearance of the food.

Not all processed foods are unhealthy. Some processed foods can be a healthy part of a balanced diet. For example, canned fruits and vegetables can be a good source of vitamins and minerals. However, it is important to be aware of the ingredients in processed foods and to choose options that are lower in added sugars, unhealthy fats, and sodium.

What is Food Processing Industry

The food processing industry is all about taking fresh food and giving it a makeover! Imagine it like a giant kitchen that turns things like vegetables, fruits, and grains into the yummy things you see at the store.

Here’s what they do:

Make food last longer: They help keep food fresh by things like freezing, canning, and drying. This way, we can enjoy yummy fruits and veggies even when they’re not in season!

Make food easier to eat: They chop, slice, and cook food to make it easier to prepare meals.

Make food tastier: Sometimes they add a little flavor or mix things together to create new treats.

So next time you see your favorite yogurt or bag of frozen peas, remember the food processing industry helped make it possible!

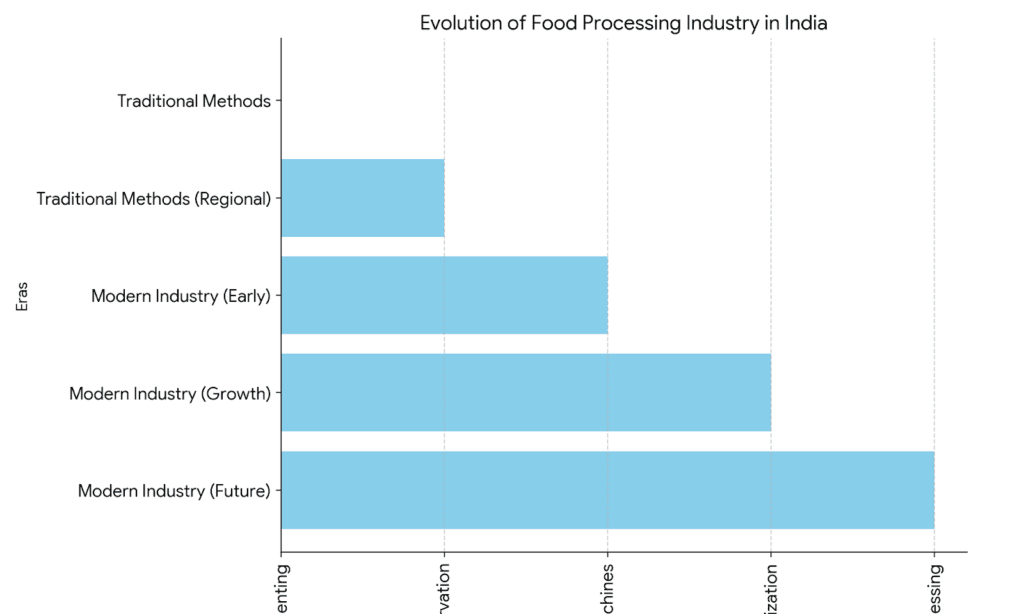

History of Food Processing Industry in India

The food processing industry in India has a rich history dating back centuries, but significant modern developments began during the colonial period and have continued to evolve since independence in 1947. Here’s an overview of its history:

Pre-Colonial Era: India has a long tradition of food processing, with techniques like pickling, fermentation, and drying being practiced for preservation and flavor enhancement. Spices, in particular, played a significant role in India’s trade relations with other civilizations.

Colonial Influence (18th to 20th Century): During British colonial rule, the food processing industry began to take shape with the establishment of modern processing methods and infrastructure. The British introduced techniques for canning, milling, and refining, primarily to serve their interests in exporting processed foods back to Britain.

Post-Independence Era (1947 onwards):

Green Revolution: In the 1960s and 1970s, India underwent the Green Revolution, which led to significant increases in agricultural productivity. This surplus agricultural produce laid the foundation for the growth of the food processing industry.

Industrial Policy Reforms: Starting from the 1980s, India began liberalizing its economy, leading to the gradual dismantling of the License Raj and opening up of the market. This allowed for greater private investment and growth in the food processing sector.

Technology and Innovation: With advancements in technology and the introduction of modern processing techniques, the industry witnessed a transformation. This included the adoption of machinery for milling, grinding, packaging, and preservation, as well as the introduction of cold storage facilities and food additives.

Government Initiatives: The Indian government has implemented various policies and initiatives to promote the food processing industry. This includes financial incentives, subsidies, and the establishment of specialized institutions such as the Ministry of Food Processing Industries (MoFPI) in 1988.

Recent Developments (21st Century):

Foreign Investment: India has attracted significant foreign investment in the food processing sector due to its large consumer base and growing middle class.

Organized Retail: The rise of organized retail chains has created new opportunities for food processors to reach consumers through modern distribution channels.

Health and Wellness Trends: There is a growing demand for healthier and more natural food products, leading to innovations in the industry such as organic food processing and functional foods.

Export Market: India has become a major player in the global food processing market, exporting a wide range of processed food products to various countries.

Overall, the food processing industry in India has come a long way from traditional methods to modern, technologically advanced processes, driven by a combination of historical influences, government policies, technological advancements, and changing consumer preferences.

Fact About Indian Food Processing Industry

Here are 10 facts about the Indian food processing industry:

- Ancient Roots, Modern Boom: While traditional food preservation techniques have existed for millennia, the modern food processing industry with factories and machinery emerged in the 19th or early 20th century, coinciding with India’s industrialization.

- Agri-Powerhouse: India is a leading producer of various agricultural products, including milk (world’s largest producer), fruits and vegetables, spices, and marine products. This rich agricultural base provides a strong foundation for the food processing industry.

- Sub-Sector Strength: The Indian food processing industry is a vast and diverse sector. Key sub-segments include fruits & vegetables processing, dairy processing, poultry & meat processing, fisheries, and grain processing.

- Employment Generator: The industry is a significant employer in India, providing jobs across various skillsets, from production workers to food scientists and engineers.

- Government Initiatives: The Indian government actively supports the growth of the food processing industry through various initiatives like the “One District, One Product (ODOP)” scheme, which promotes local specialties.

- Rising Demand: India’s growing population and increasing disposable income are driving up the demand for processed and packaged foods, offering a significant market for the industry.

- Export Power: India is a major exporter of processed food products like rice, sugar, and processed fruits and vegetables. The seafood industry has also seen significant export growth.

- Innovation Focus: The industry is increasingly focusing on innovation, developing new products and processes to cater to evolving consumer preferences, such as healthier and more convenient food options.

- Cold Chain Challenge: India faces challenges in developing a robust cold chain infrastructure, which is critical for minimizing food spoilage and waste. Investments are being made to improve cold storage and transportation facilities.

- Future Potential: With its strong agricultural base, growing domestic market, and export potential, the Indian food processing industry is poised for significant growth in the coming years. The industry is expected to reach a value of $535 billion by 2025-2026!

Top Food Processing Companies in North East India

The North Eastern region of India holds immense potential for food processing, but the sector is still developing. There aren’t many large established national players set up there yet. However, there are several promising regional companies focusing on processing local fruits, vegetables, and other agricultural produce. Here are five such companies to know about:

- North East Mega Food Park: Located in Tihu, Assam, this is a government-backed initiative to boost food processing in the region. It provides infrastructure and support services to food processing units.

- SRD Nutrients Pvt. Ltd.: Based in Assam, SRD Nutrients processes and manufactures rice bran oil, cattle feed, and organic manure.

- WIDTH MARKETING PVT LTD.: Situated in Assam, WIDTH MARKETING specializes in processing and exporting spices like turmeric, ginger, and black pepper.

- M/s.蹒மை (蹒மை meaning Progress in Assamese): This company based in Dima Hasao, Assam processes and packages black rice, a specialty of the region known for its unique aroma and health benefits.

- Arunachal Pradesh Food Processing Unit: This is a government initiative in Arunachal Pradesh that processes local fruits like kiwi, orange, and pineapple into jams, jellies, and squashes.

It’s important to note that this list is not exhaustive, and there are many other upcoming food processing units in the North Eastern region of India. The future looks bright for the industry in this part of the country!

Top Food Processing Companies in North India

North India is home to a well-established food processing industry with a mix of multinational giants and strong domestic players. Here are some of the top companies in the region:

Major National and Multinational Players:

Nestle: A Swiss multinational with a significant presence in India, known for Maggi, KitKat, and a variety of milk products.

Parle Agro: An Indian company leading the beverage sector with brands like Frooti, Appy Fizz, and Bailey.

Britannia Industries: A prominent Indian company producing biscuits, cakes, dairy products, and more.

ITC Limited: An Indian conglomerate with a diverse food portfolio including biscuits, snacks, chocolates (under ITC Kitchens brand), and staples.

PepsiCo India: The Indian arm of PepsiCo, a leading manufacturer of beverages (Pepsi, Slice) and snacks (Kurkure, Lays).

Hindustan Unilever Limited (HUL): A subsidiary of Unilever, HUL offers a wide range of processed food items like Knorr soups, Kissan jams & spreads, Bru coffee, and Kwality Walls ice-cream.

Strong Regional Players in North India:

Haldiram’s: A Delhi-based company famous for its wide range of snacks, sweets, and ready-to-eat meals.

Mother Dairy: Owned by cooperatives, Mother Dairy is a major player in the Delhi NCR region for milk, dairy products, and paneer.

MTR Foods: A Bengaluru-based company, MTR has a strong presence in North India with its ready-to-eat mixes, spices, and instant noodles.

Dabur India Ltd.: A leading Indian company headquartered in Ghaziabad, Dabur offers a variety of processed food products like juices, honey, and Real fruit extracts.

Godrej Consumer Products Limited: This Mumbai-based company offers several food products in North India, including their Yummiez instant noodles and freshness range (Happilo).

Top Food Processing Companies in Western India

While Western India boasts a thriving food processing industry, it may not have as many nationally recognized giants headquartered there compared to North India. However, the region is a powerhouse for several strong domestic players and some prominent multinational companies with a significant presence. Here are 5 top contenders for the top processors in Western India:

- Vadilal Industries Ltd.: This Gujarat-based company is a household name for ice-creams and frozen treats across India. They’ve been around for decades and dominate the frozen dessert segment in Western India.

- Godrej Tyson Foods: A joint venture between Godrej Consumer Products Limited (India) and Tyson Foods (USA), this company leverages its strengths in both poultry processing and branded consumer foods. They are a major player in Western India’s poultry sector.

- Pradeep Pickles Pvt. Ltd.: Located in Maharashtra, Pradeep Pickles is a leading manufacturer and exporter of pickles, chutneys, and papads. They are known for their traditional recipes and a wide variety of regional specialties.

- Aachi Foods Ltd.: This company from Gujarat is a major player in spices, pulses, and ready-to-eat mixes. They cater to both domestic and international markets and are known for their high-quality products.

- Maharashtra Agro Industries Corporation (MAHA-AIC): This government undertaking in Maharashtra focuses on processing and marketing agricultural produce. They work with farmers and cooperatives to process fruits, vegetables, and other agricultural products, contributing significantly to the food processing sector in the state.

Top Food Processing Companies in South India

South India boasts a well-developed food processing industry with a strong presence of both national and regional players. Here are some of the top companies in the region:

Major National and Multinational Players:

Nestle India: The Indian arm of the Swiss giant Nestle has a significant presence in South India, manufacturing popular products like Maggi noodles, KitKat chocolates, and milk powders.

Britannia Industries: This leading Indian company produces a wide variety of processed food items like biscuits, cakes, rusks, and dairy products, with a strong market presence in South India.

ITC Limited: The Indian conglomerate ITC offers a diverse food portfolio in South India, including biscuits, snacks, and staples like rice and wheat under their popular brands like Aashirvaad and Bingo!

PepsiCo India: PepsiCo has a strong presence in South India, manufacturing popular beverages like Pepsi and Slice and popular snack brands like Kurkure and Lays.

Hindustan Unilever Limited (HUL): A subsidiary of Unilever, HUL offers a wide range of processed food items across South India, including Knorr soups, Kissan jams & spreads, Bru coffee, and Kwality Walls ice-cream.

Strong Regional Players in South India:

Parle Agro: This leading Indian company headquartered in Mumbai has a major stronghold in South India, particularly known for its popular beverage brands like Frooti, Appy Fizz, and Bailey.

Everest Industries Ltd.: A Kerala-based company, Everest is a major player in spices, condiments, and ready-to-eat mixes across South India. They are known for their high-quality products and focus on South Indian flavors.

ID Fresh Food (India) Ltd.: Based in Andhra Pradesh, ID Fresh is a leading manufacturer of popular breakfast options like idly and dosa batter, along with other ready-to-eat and ready-to-cook products.

Ponni Sugars (India) Ltd.: Located in Tamil Nadu, Ponni Sugars is a major player in sugar refining and also manufactures other food products like pulses and sunflower oil.

NRM Group: This Bengaluru-based company has a strong presence in South India with its Nandini brand of milk and dairy products, including ghee, paneer, and curd.

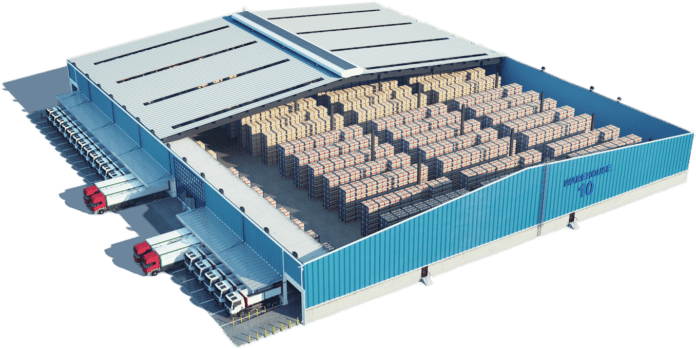

Why ABCC

ABCC India Project Cargo, with its expertise and specialized services, is an excellent choice for transporting goods for the food processing industry. Here are some positive aspects to highlight:

- Specialized Handling: ABCC India Project Cargo understands the unique requirements of transporting goods for the food processing industry. Their specialized handling ensures that perishable items, fragile equipment, and other sensitive products are transported with the utmost care and attention to detail.

- Customized Solutions: They offer customized transportation solutions tailored to the specific needs of food processing companies. Whether it’s temperature-controlled containers for perishable goods or secure packaging for fragile equipment, ABCC India Project Cargo ensures that each shipment is handled appropriately.

- Reliability and Timeliness: With a strong track record of reliability and on-time delivery, ABCC India Project Cargo instills confidence in their clients. They understand the importance of timely delivery, especially in the food processing industry where delays can impact product quality and supply chain efficiency.

- Safety and Compliance: ABCC India Project Cargo adheres to strict safety standards and regulatory compliance, ensuring that all shipments comply with food safety regulations and industry standards. This commitment to safety and compliance provides peace of mind to food processing companies entrusting their goods to them.

- Efficient Logistics Network: Leveraging their extensive logistics network and strategic partnerships, ABCC India Project Cargo offers efficient transportation solutions that optimize routes, reduce transit times, and minimize costs. This efficiency translates to tangible benefits for food processing companies, including improved supply chain management and cost savings.

- Customer-Centric Approach: Above all, ABCC India Project Cargo prioritizes customer satisfaction. Their team of experienced professionals goes above and beyond to understand their clients’ needs and deliver exceptional service every step of the way. Whether it’s providing real-time tracking updates or resolving any issues that may arise, they ensure a seamless experience for their customers.

In summary, ABCC India Project Cargo is a trusted partner for food processing companies, offering specialized services, customized solutions, reliability, safety, efficiency, and a customer-centric approach that sets them apart in the industry.

Related :-

Warehouse and Warehousing Storage

Types of Warehouse

Warehouse Management WMS Services

Basic Raw Material Suppliers in Food Processing Industries (India)

| Raw Material | Supplier Category | Example Supplier Name | Why They Might Be Best |

|---|---|---|---|

| Fruits & Vegetables | Aggregator: Sources produce from various farms. | National Commodity & Derivatives Exchange Limited (NCDEX) | – Wide variety of produce – Established platform for secure transactions |

| Fruits & Vegetables | Regional Farmer Cooperatives | State Horticulture Mission (varies by state) | – Fresh, local produce – Supports local farmers |

| Grains (Rice, Wheat, etc.) | Government Agencies | Food Corporation of India (FCI) | – Reliable source, good quality control – Stable pricing |

| Grains (Rice, Wheat, etc.) | Private Milling Companies | ITC Ltd. (Agri Business Division) | – Large-scale processing capabilities – Consistent supply |

| Milk & Dairy Products | Cooperatives & Producer Unions | Amul Dairy | – High-quality milk – Supports dairy farmers |

| Milk & Dairy Products | Private Processing Companies | Mother Dairy | – Established brand – Diverse product range |

| Spices | Wholesale Spice Merchants | [Spice Market in Your City] (e.g., Khari Baoli, Delhi) | – Direct access to a variety of spices – Competitive pricing |

| Spices | Large Spice Processing Companies | Aachi Foods Ltd. | – Standardized quality – Large-scale production capabilities |

| Meat & Poultry | Government-approved Processing Plants | [Local Poultry Processing Plant] | – Adheres to safety regulations – Verified source of meat |

| Meat & Poultry | Integrated Poultry Companies | Godrej Tyson Foods | – Control over entire production chain – Consistent quality |

Food Processing Machine Manufacturers

| Company Name | Location | Product Focus | Website |

|---|---|---|---|

| Buhler Group | Switzerland (Global Presence) | Industrial food processing machinery (grains, milling, snacks, etc.) | https://www.buhlergroup.com/global/en/homepage.html |

| Tetra Pak | Sweden (Global Presence) | Packaging solutions for food and beverages | https://www.tetrapak.com/ |

| GEA Group | Germany (Global Presence) | Food processing equipment for various applications (dairy, meat, beverages) | https://www.gea.com/en/unitedstates/ |

| Alfa Laval | Sweden (Global Presence) | Separation and processing equipment for various food applications | https://www.alfalaval.in/ |

| Larsen & Toubro (L&T) | Mumbai, India | Diverse range of machinery, including food processing equipment | https://www.larsentoubro.com/ |

| Voltas Limited | Mumbai, India | Air conditioning, refrigeration, and food processing equipment | https://www.voltas.com/ |

| SPX Flow India Pvt. Ltd. | Pune, India | Food processing equipment for pumps, mixers, and separation | https://www.spxflow.com/ |

| Jindal Stainless Limited | Hissar, India | Stainless steel for various industries, including food processing equipment | https://stainlessmart.jindalstainless.com/ |

| Everest Engineers Group | Kolhapur, India | Spices, pulses, and food processing equipment | https://everestengg.in/article/ |

| Aquatech Engineers | Ahmedabad, India | Food processing and dehydration equipment | https://www.aquatechengineers.in/ |

Food Processing Industry Contribution in Indian Economy

The food processing industry is a significant contributor to the Indian economy in several ways. Here’s a breakdown of its impact:

1. Share of GDP and Employment:

GDP Contribution: The food processing industry contributes around 12.22% of employment in the registered manufacturing sector and its Gross Value Added (GVA) has been continuously increasing, reaching ₹2.37 lakh crore in 2020-21. While a target for its contribution to GDP isn’t set, various initiatives aim to increase its share.

2. Job Creation:

Employment Generator: The industry employs a significant portion of the workforce, particularly in rural areas. It provides jobs across various skillsets, from production workers to food scientists and engineers.

3. Boosting Agriculture:

Strong Foundation: India’s position as a leading producer of various agricultural products like milk, fruits & vegetables, spices, and marine products provides a strong raw material base for the food processing industry.

Reduced Food Wastage: Processing helps preserve food, extending shelf life and reducing spoilage, which benefits both farmers and consumers.

4. Export Potential:

Export Powerhouse: India is a major exporter of processed food products like rice, sugar, processed fruits & vegetables, and seafood. This generates foreign income and creates a global market for Indian agricultural produce.

5. Economic Growth:

Value Addition: Processing adds value to agricultural products, increasing their market price and generating higher income for farmers and businesses involved in the industry.

6. Innovation and Technology:

Focus on Innovation: The industry is increasingly focusing on innovation, developing new products and processes to cater to evolving consumer preferences, such as healthier and more convenient food options.

7. Overall Development:

Rural Development: By creating jobs and processing local produce, the food processing industry contributes to rural development and uplifts the economic conditions of rural communities.

Challenges:

Cold Chain Infrastructure: Developing a robust cold chain infrastructure to minimize food spoilage and waste remains a challenge. This requires investments in storage and transportation facilities.

Integration of Farmers: Ensuring better integration of farmers with the food processing industry to provide them with fair prices and access to markets is crucial.

Future Potential:

With its strong agricultural base, growing domestic market, and export potential, the Indian food processing industry is poised for significant growth in the coming years. The industry is expected to reach a value of $535 billion by 2025-2026!

Transportation Industry Impact Food Processing Industry

The transportation industry plays a crucial role in the food processing industry, impacting it in several ways:

Positive Impacts:

Wider Market Reach: Efficient transportation allows processed food products to be distributed across vast distances, reaching a wider customer base. This benefits both consumers (greater access to variety) and food processing companies (expanded market opportunities).

Economies of Scale: Transportation facilitates large-scale production and distribution of processed foods. This allows companies to achieve economies of scale, reducing production costs and making processed food more affordable for consumers.

Seasonal Availability: Transportation helps bridge the gap between seasons. Food processing companies can source ingredients from different regions based on seasonal availability, ensuring a year-round supply of raw materials.

Specialization and Efficiency: Transportation enables food processing companies to specialize in specific products or processes. They can source raw materials from regions best suited for their production and transport finished goods to locations with high demand. This fosters efficiency and optimizes resource allocation.

Just-in-Time Inventory Management: Reliable and efficient transportation allows food processing companies to adopt just-in-time inventory management practices. This minimizes storage space requirements and reduces the risk of spoilage for perishable items.

Negative Impacts:

Food Spoilage and Waste: Inefficient or unreliable transportation can lead to spoilage of perishable food items during transport. This results in economic losses for food processing companies and wasted resources.

Temperature Control: Maintaining proper temperature control throughout the transportation process is crucial for some food items. Inadequate refrigeration or temperature control can compromise food safety and quality.

Fuel Costs and Emissions: Transportation relies heavily on fossil fuels, contributing to greenhouse gas emissions and environmental concerns. The food processing industry needs efficient and sustainable transportation solutions to minimize its environmental footprint.

Infrastructure Challenges: Poor road conditions, inadequate storage facilities at transport hubs, and inefficient logistics can all contribute to delays and disruptions in the food supply chain. This can negatively impact the timeliness and quality of food deliveries.

The Future:

The future of the transportation industry’s impact on food processing likely involves:

Improved Infrastructure: Investments in better roads, cold storage facilities, and logistics management systems will be crucial for maintaining efficient and reliable food transport.

Sustainable Practices: The adoption of cleaner fuels, electric vehicles, and optimized routes can help reduce the environmental impact of food transportation.

Technological Advancements: Technologies like real-time temperature monitoring, smart packaging, and blockchain for supply chain transparency can enhance food safety and efficiency in transportation.

By working together, the transportation and food processing industries can ensure a reliable, efficient, and sustainable food supply chain that minimizes waste and environmental impact.

Worldwide Top Food Processing Companies

Here’s a breakdown of the top food processing companies worldwide, considering factors like revenue, market capitalization, and global reach:

Top contenders based on Revenue (2023 estimates):

- Nestlé (Switzerland): A global giant with a massive portfolio of food and beverage products like Maggi, KitKat, Nescafe, and Purina.

- PepsiCo (USA): A leading producer of beverages (Pepsi, Slice) and snacks (Kurkure, Lays) with a strong presence worldwide.

- Archer Daniels Midland Company (ADM) (USA): A processing and trading giant focusing on agricultural products like corn, soybeans, and wheat.

- JBS (Brazil): The world’s largest meat processing company, specializing in beef, pork, and poultry.

- Mondelez International (USA): Well-known for chocolate brands like Cadbury and Milka, and biscuit brands like Oreo and Chips Ahoy!

- The Kraft Heinz Company (USA): Produces a variety of food products like Heinz ketchup, Kraft cheese, and Oscar Mayer meats.

- Coca-Cola Company (USA): The world’s leading beverage company with a focus on colas, but also offers juice and water brands.

- Unilever (British-Dutch): A consumer goods giant with a significant food and beverage portfolio including brands like Hellmann’s mayonnaise, Knorr soups, and Lipton tea.

- Yili Group (China): The largest dairy company in Asia, with a growing presence in other food categories.

- Cargill (USA): A major player in agricultural processing and trading, with a diverse food and beverage portfolio.

Additional Factors to Consider:

Market Capitalization: While revenue indicates overall sales, market capitalization reflects a company’s overall stock market value. Companies like Nestle and Mondelez International often rank high in terms of market cap.

Regional Variations: The top players may vary depending on the specific region. For example, companies like ITC (India) or BRF (Brazil) might be prominent in their respective regions but not necessarily rank at the global level based solely on revenue.

Where in India is the Largest Favorable Market for Food Processing industries ?

The Indian food processing industry has seen growth and opportunities across various regions of the country. However, some states have emerged as particularly favorable locations for food processing industries due to factors such as agricultural abundance, infrastructure, policy support, and market demand. One such state is Uttar Pradesh (UP), which has emerged as one of the largest and most favorable markets for the food processing industry in India. Here’s why:

- Abundant Agricultural Produce: Uttar Pradesh is blessed with diverse agro-climatic conditions, fertile land, and abundant water resources, making it a major producer of a variety of agricultural commodities such as fruits, vegetables, grains, and dairy products. This abundance of raw materials provides a strong foundation for the food processing industry.

- Strategic Location: Situated in the heart of northern India, Uttar Pradesh has excellent connectivity through road, rail, and air networks. It shares borders with several states, including Delhi, Haryana, Rajasthan, and Bihar, facilitating easy access to both domestic and international markets.

- Government Support: The Uttar Pradesh government has implemented various policies and initiatives to promote the food processing industry in the state. This includes incentives such as subsidies, tax benefits, and infrastructure support to attract investments and facilitate the establishment of food processing units.

- Growing Consumer Market: Uttar Pradesh is home to a large and diverse population, including urban centers such as Lucknow, Kanpur, and Varanasi, which have a growing demand for processed food products. Additionally, the state’s proximity to the National Capital Region (NCR) provides access to a lucrative market with high purchasing power.

- Infrastructure Development: Uttar Pradesh has been investing in developing infrastructure such as food parks, cold storage facilities, and logistics hubs to support the food processing industry. These infrastructure developments improve supply chain efficiency and reduce post-harvest losses.

- Focus on Value Addition: With increasing awareness about food safety, quality, and nutritional value, there is a growing demand for value-added processed food products. Uttar Pradesh offers opportunities for value addition through processing, packaging, and branding of agricultural produce, catering to both domestic and export markets.

Overall, Uttar Pradesh’s favorable agricultural base, strategic location, government support, growing consumer market, infrastructure development, and focus on value addition make it one of the largest and most attractive markets for the food processing industry in India.

Dark Time of Food Processing Industries in India

The food processing industry in India, like any other sector, has faced challenges and downturns at various times. Here are some of the darker periods or challenges that the food processing industry in India may have encountered:

- Supply Chain Disruptions: The industry has faced challenges related to supply chain disruptions, especially during times of natural disasters, political unrest, or global pandemics. These disruptions can lead to delays in sourcing raw materials, transportation issues, and difficulties in meeting production demands.

- Food Safety Concerns: Incidents of food contamination, adulteration, and safety scandals have affected consumer trust and confidence in processed food products. Food safety regulations and enforcement mechanisms have sometimes been inadequate, leading to lapses in quality control and hygiene standards.

- Infrastructure Constraints: Inadequate infrastructure, including cold storage facilities, transportation networks, and processing plants, has hindered the growth of the food processing industry. Limited access to modern technology and equipment has also hampered efficiency and productivity.

- Policy and Regulatory Challenges: Complex regulatory frameworks, bureaucratic hurdles, and inconsistent policies have posed challenges for food processing companies, especially small and medium-sized enterprises (SMEs). Uncertainty regarding taxation, land acquisition, and licensing procedures has deterred investment and expansion in the sector.

- Market Volatility: Fluctuations in commodity prices, currency exchange rates, and consumer preferences can impact the profitability and viability of food processing businesses. Increased competition, both domestically and internationally, has further intensified market volatility and pricing pressures.

- Environmental Concerns: The food processing industry, like other manufacturing sectors, has come under scrutiny for its environmental footprint. Issues such as water usage, waste management, and carbon emissions have raised concerns about sustainability and environmental responsibility.

- Labour Challenges: Labour shortages, skilled workforce gaps, and labor disputes have posed challenges for food processing companies, affecting production schedules and operational efficiency. Ensuring fair wages, employee safety, and labor rights remains a significant concern for the industry.

Despite these challenges, the food processing industry in India has shown resilience and adaptability, leveraging opportunities for innovation, technology adoption, and market expansion. Government initiatives aimed at improving infrastructure, streamlining regulations, promoting investment, and enhancing food safety standards have also helped address some of the darker times faced by the industry.

Food Processing Industry Conclusion

The food processing industry is a crucial sector in India, playing a vital role in the country’s economy and food security. Here’s a concluding summary of its key aspects:

Significance:

Economic Growth: Contributes to GDP growth, creates jobs, and boosts exports of processed food products.

Value Addition: Processing adds value to agricultural produce, increasing farmer income and creating a market for crops.

Food Security: Extends shelf life and reduces food spoilage, ensuring greater access to nutritious food throughout the year.

Improved Nutrition: Fortification of processed foods can address nutritional deficiencies in some regions.

Wider Food Variety: Offers convenient and diverse food options for consumers.

Challenges:

Infrastructure Gaps: Cold chain infrastructure needs improvement to minimize spoilage and waste.

Integration of Farmers: Ensuring better integration of farmers with the industry to provide fair prices and market access is crucial.

Waste Management: Environmentally friendly disposal of processing waste is an ongoing concern.

Nutritional Concerns: Excessive reliance on processed foods with high sodium, sugar, and unhealthy fats can pose health risks.

Future Potential:

Innovation: Focus on new technologies and processes can create healthier, more convenient, and sustainable food options.

Sustainability: Adopting sustainable practices in agriculture, processing, and packaging is essential for the future.

Government Support: Continued government initiatives and policies promoting investment and infrastructure development are crucial.

Overall, the food processing industry in India has a bright future. By addressing the challenges and embracing innovation, the industry can contribute significantly to India’s economic growth, food security, and the well-being of its citizens.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

chocolate biscuit manufacturer manufacturing process and companies :-

Ministry of Food Processing Industries :- www.mofpi.nic.in

NOTE :- From our point of view, the biggest problem today is that due to mistrust, disagreement, insecurity, today the price of our business and daily essential commodities and raw materials is increasing infinitely unnecessary.We have a small effort which is expected that every good buyer should get a good seller without a middleman and a good seller gets a good buyer.We always provide advanced information on our behalf to our customers. If you are interested in public interest by the presentation and renewal of your business, then share with us by people what revolutionary changes you have made to your business that have benefited the people.So that our good business community and you also benefit forever. And people should benefit so that a good business environment is created.

Advantage Our Pro Membership :-We provide advanced support to our pro membership clients in Transportation, Logistics, Warehousing, Finance etc….

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

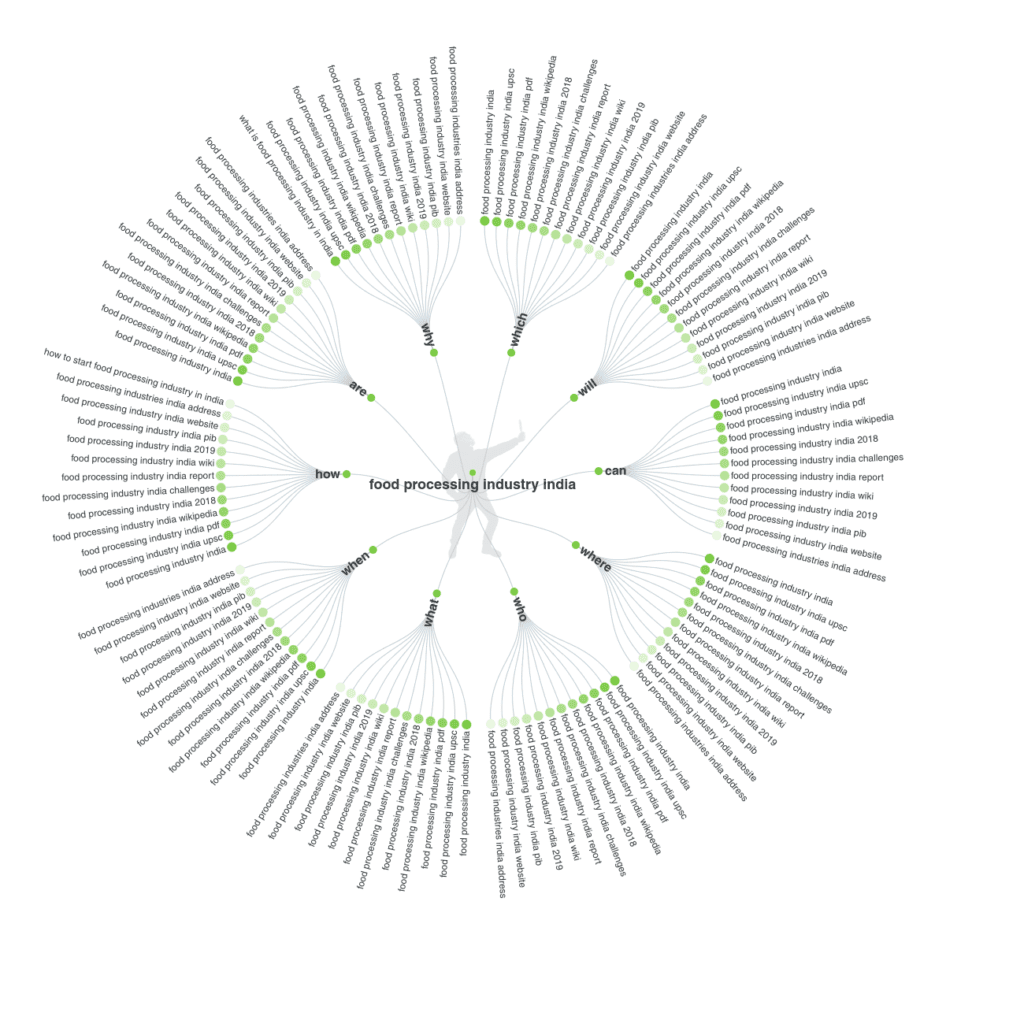

Public frequently asked questions (FAQs):-

What is advantage of food?

Heart health. A healthy diet rich in fruits, vegetables, whole grains and low-fat dairy can help to reduce your risk of heart disease by maintaining blood pressure and cholesterol levels. High blood pressure and cholesterol can be a symptom of too much salt and saturated fats in your diet.

What are disadvantages of food?

An unhealthy diet high in fat, added sugar and salt, such as one containing a lot of highly-processed foods, can increase your risk for cancer, Type 2 diabetes and heart disease, according to the World Health Organization.

Which vitamin is lost during processing of food ?

An unhealthy diet high in fat, added sugar and salt, such as one containing a lot of highly-processed foods, can increase your risk for cancer, Type 2 diabetes and heart disease, according to the World Health Organization.

Which vitamin is lost during processing of food?

Some vitamins are more stable (less affected by processing) than others. Water-soluble vitamins (B-group and C) are more unstable than fat-soluble vitamins (K, A, D and E) during food processing and storage. The most unstable vitamins include: folate, thiamine and vitamin C.

What is food processing and its purpose?

Food processing involves the transformation of raw animal or plant materials into consumer-ready products, with the objective of stabilising food products by preventing or reducing negative changes in quality.

What is food processing and its types?

Food Processing is the process of transforming food items into a form that can be used. It can cover the processing of raw materials into food via different physical and chemical processes. Various activities covered in this process are mincing, cooking, canning, liquefaction, pickling, macerating and emulsification.

What are the 3 categories of food processing?

Food processing methods fall into three categories: primary, secondary and tertiary.

What are examples of food processing ?

Primary processing is the conversion of raw materials to food commodities. Milling is an example of primary processing. Secondary processing is the conversion of ingredients into edible products – this involves combining foods in a particular way to change properties. Baking cakes is an example of secondary processing.

What are processing techniques in food?

Food processing and preparation activities cover three main fields:

(1) the preservation of foods by

(a) modern methods such as refrigeration, canning and irradiation, and

(b) traditional methods such as drying, salting, smoking and fermentation

(2) the development of protein – rich foods

(3) food additives.

What are the primary processing?

Primary processing is the conversion of raw materials into food commodities – for example, milling wheat into flour. Secondary processing is when the primary product is changed to another product – for example, turning wheat flour into bread.

What are high risk foods?

High risk foods share a tendency to spoil as a result of unsuitable storage conditions or improper cooking methods. Meats, fish, gravy, sauces, shellfish, dairy products, pasta and even cooked rice are all examples, and the smallest errors can lead to contamination.

What is the temperature danger zone for food?

Bacteria grow most rapidly in the range of temperatures between 40 °F and 140 °F, doubling in number in as little as 20 minutes. This range of temperatures is often called the “Danger Zone.” Never leave food out of refrigeration over 2 hours.

How can you reduce wastage of food in your home?

how to reduce food waste in the home, at school,at office and on the go.

Avoid buying too much.

Think twice before throwing food away.

Always make a shopping list.

Organising the kitchen with FIFO.

Store food correctly.

Make a weekly menu.

Keep a log of spoiled foods.

Freeze extras.

What are the methods of food preservation?

Among the oldest methods of preservation are drying, refrigeration, and fermentation. Modern methods include canning, pasteurization, freezing, irradiation, and the addition of chemicals.

What are the genuine reasons for food processing?

Almost all food is processed in some way before it is eaten. Commercially, the main reasons to process food are to eliminate micro-organisms (which may cause disease) and to extend shelf life. Simply cooking or combining a food with other foodstuffs to create a recipe is also considered a form of food processing.

food processing a good career?

The food processing sector is still in its early stage that promises numerous job opportunities. It is a lucrative and attractive sector that assures that trained professionals from various disciplines find good jobs for themselves.

How can you tell if food is processed?

“Processed food” includes food that has been cooked, canned, frozen, packaged or changed in nutritional composition with fortifying, preserving or preparing in different ways. Any time we cook, bake or prepare food, we’re processing food.

What are the disadvantages of food processing?

The Many Health Risks of Processed Foods

Increased cancer risk.

Too much sugar, sodium and fat.

Lacking in nutritional value.

Calorie dense and addicting.

Quicker to digest.

Full of artificial ingredients.

Which is not a method of food preservation?

Ex. Salting of the food ads a large amount of solute to the food as a result of this there is exosmosis of water from the body of the microorganisms bacteria and fungi as. Due to this process of exosmosis they die.

What are the traditional methods of food preservation?

Traditional methods of preservation include smoking, drying, salting, and fer- mentation, or a combination of these methods may be applied. Other short-term preservation methods used are deep-fat frying and steaming with salt.

What is salting method?

Salting is a process where the common salt (NaCl), sodium chloride, is used as a preservative that penetrates the tissue; hence slows the bacterial growth and deactivates the enzymes.Dry salting, brine salting and mixed salting are commonly used methods in salting of fish. Salting of seafood is done with salt.

What are the advantages and effects of food processing?

Processing (including preparation) makes food healthier, safer, tastier and more shelf-stable. While the benefits are numerous, processing can also be detrimental, affecting the nutritional quality of foods. Blanching, for example, results in leaching losses of vitamins and minerals.

What are unprocessed foods list?

Unprocessed or minimally processed foods: Think vegetables, grains, legumes, fruits, nuts, meats, seafood, herbs, spices, garlic, eggs and milk. Make these real, whole foods the basis of your diet.

What is primary processing of food?

Primary processing involves cutting, cleaning, packaging, storage and refrigeration of raw foods to ensure that they are not spoilt before they reach the consumer.Secondary food production involves converting raw food ingredients into more useful or edible forms.

What happens when food is stored?

Improper food storage can lead to several problems, including bacteria and mold growth, food spoilage through natural decay, and even food waste, which costs billions of dollars annually worldwide. Below are some of the areas that are affected by improper storing of food.

What is the importance of food preservation?

Food preservation stops the growth of micro – organisms (such as yeasts) or other micro – organisms (although some methods work by presenting benign bacteria or fungi into the food), and slows the oxidation of rancid-causing fats.

What are causes of food poisoning?

The top seven causes of food poisoning are Salmonella, Listeria, Staphylococcus, Trichinosis, E. coli, Campylobacter, Clostridium.

What are the consequences of food processing?

Heavily processed foods often include unhealthy levels of added sugar, sodium and fat. These ingredients make the food we eat taste better, but too much of them leads to serious health issues like obesity, heart disease, high blood pressure and diabetes. Lacking in nutritional value.

What are the effects of food processing?

Processing (including preparation) makes food healthier, safer, tastier and more shelf-stable. While the benefits are numerous, processing can also be detrimental, affecting the nutritional quality of foods. Blanching, for example, results in leaching losses of vitamins and minerals.

What are high risky foods?

Dairy products (milk, cream, cheese, yogurt, and products containing them such as cream pies and quiches)

Eggs.

Meat or meat products.

Poultry.

Fish and seafood.

Why is rice a extreme high risk food?

Rice is one of the most eaten foods on the planet and is also considered a high-risk food when it comes to food poisoning. It can become contaminated with Bacillus cereus, which can initially infect and live in uncooked rice as spores.

flour a high risk food?

These foods include cereals, flour, sugar, unopened canned goods, dried products, sauces and spices. They do not support the growth of bacteria like the high risk/high moisture foods. They can lose quality from being kept too long in storage and their major source of contaminants is pests.

Can reheating rice kill you?

Does reheating cooked rice kill the bacteria? No, reheating cooked rice before eating does not kill the spores or and any toxins that have already been produced and can still make you ill.

What is the difference between high-risk and low risk foods?

‘Low-risk foods’ like breads and produce must still be handled properly to ensure safety and prevent food-borne illness. High-risk foods provide the ideal conditions for bacterial growth, so they need to be handled very carefully to prevent food poisoning

Which name is taken more in the packaged food processing industry?

Patanjali is more famous in the name of Swadeshi.

cake a high risk food?

High-risk foods such as sandwiches, salads, cream cakes, desserts and items containing meat e.g. sausage rolls etc should be avoided where possible due to the additional hazards and controls required, and in any case they should not be homemade.

packaged food suitable and suitable from the point of view of health?

On average, packaged food is used to satisfy hunger in an unsafe environment. Its excessive use is unsafe and questionable

food processing industry contribution Indian GDP ?

The food processing industry is valued at US$258 billion, and is the fifth largest industry domestically in terms of production, consumption, export, and expected growth in the country. It contributes to around 14 percent of manufacturing Gross Domestic Product (GDP) and 13 percent of India’s total food exports.

What is the status of the food processing industry in India?

The Indian gourmet food market is currently valued at US$ 1.3 billion and is growing at a Compound Annual Growth Rate (CAGR) of 20 per cent. India’s organic food market is expected to increase by three times after 2020 .

What are the four major sectors in the food industry?

Food industry mainly consists of four distinct sectors: the farm service sector, the producers sector, the processors sector and the marketers sector. While the major services performed by each sector is distinct, many firms in the food industry have vertically integrated across sector boundaries.

How big is the food industry in India?

The Indian food retail market is expected to reach Rs 61 lakh crore (US$ 894.98 billion) by 2020. The Indian food processing industry accounts for 32 per cent of the country’s total food market, one of the largest industries in India and is ranked fifth in terms of production, consumption, export and expected growth.

food processing industry contribution Indian transportation industry ?

Container trucks grew by 30% in the Indian transportation business from the packaged food processing industry. But due to transportation problems due to not getting proper fare, the cost of this food processing business increases by 8 to 30%.