🧱 INTRODUCTION — What Is Cement: The Foundation Stone of Civilization

Cement — a humble grey powder — is far more than a building material. It is the invisible force that shaped cities, connected continents, and built civilizations from the ground up. In the simplest words, cement is a binding material that, when mixed with water, hardens and holds sand and gravel together to form concrete — the backbone of modern construction.

But behind this ordinary substance lies an extraordinary story — a story of invention, persistence, and transformation.

Thousands of years ago, early builders discovered that certain stones, when burnt and crushed, could solidify again after mixing with water. This primitive discovery became the seed of one of the world’s most revolutionary materials. The modern version of cement was first formulated in 1824 by Joseph Aspdin, an English mason from Leeds, who patented “Portland Cement.” He named it after the Portland stone found on the Isle of Portland in England, because of the similar appearance when hardened.

Aspdin didn’t just invent a product — he ignited an industrial movement. The idea of producing a universal binding material inspired generations of engineers, architects, and builders to push boundaries. Cement became the blood in the veins of industrialization — connecting bricks, steel, and human ambition into one cohesive structure.

From ancient Roman concrete structures that still stand today to futuristic skyscrapers piercing the sky, cement has silently supported the human dream of creation and permanence. Its journey mirrors the evolution of mankind — from caves to concrete jungles, from hand tools to hydraulic plants, and from imagination to innovation.

Every road, every bridge, every home narrates a story — a story where cement plays the lead role.

Today, ABCC India Project Cargo Corporation salutes this timeless innovation. As India’s leading project logistics and heavy cargo carrier, ABCC stands at the heart of industrial growth — ensuring that every bag of cement, every structural beam, and every piece of equipment reaches its destination safely, timely, and efficiently.

Cement, after all, is not just about binding materials — it is about binding dreams, industries, and futures together.

🏗️ THE INDUSTRIALIZATION OF CEMENT: WHEN, WHERE, AND HOW IT HAPPENED

The industrialization of cement is one of humanity’s most underrated revolutions. It was not a single invention, but a series of innovations fueled by curiosity, competition, and the unstoppable force of progress.

In the early 19th century, the world was rapidly urbanizing. The Industrial Revolution had begun to reshape economies, and cities demanded durable, scalable, and cost-effective building materials. Traditional lime mortars were slow, inconsistent, and weak. Enter Portland Cement, a marvel that combined limestone and clay burned in a kiln and ground into fine powder.

By the 1850s, with improved kilns and rotary production, cement became a global commodity. The United States, Germany, and France adopted large-scale manufacturing, while India began its cement journey in 1914 with the establishment of the Indian Cement Company Ltd in Porbandar, Gujarat.

Post-independence, India witnessed massive infrastructure expansion — dams, bridges, power plants, and housing projects — each demanding higher cement output. By the 1970s and 1980s, cement production had transitioned from manual kilns to modern rotary kilns and automated grinding units.

In the 21st century, cement industrialization entered its digital phase. Plants became smarter with AI-driven quality checks, energy-efficient machinery, and environmentally controlled emissions. The focus shifted from “more production” to “sustainable production.”

Cement, once the symbol of industrial smoke and dust, is now transforming into a symbol of green innovation — recycling fly ash, using alternative fuels, and developing low-carbon variants like Green Cement and Geo-polymer Cement.

Today, India stands as the second-largest cement producer in the world, and its role in infrastructure and economic development continues to expand. Each ton of cement produced creates jobs, fuels construction, and strengthens logistics networks — including the crucial movement of raw materials and machinery handled by ABCC India Project Cargo Corporation.

The industrialization of cement is, therefore, not just a story of manufacturing — it is a story of modernization, sustainability, and human ambition.

Related :-

Trucks Truckers and Trucking

Goods Transportation Problems

Logistics Overview

Factories survey

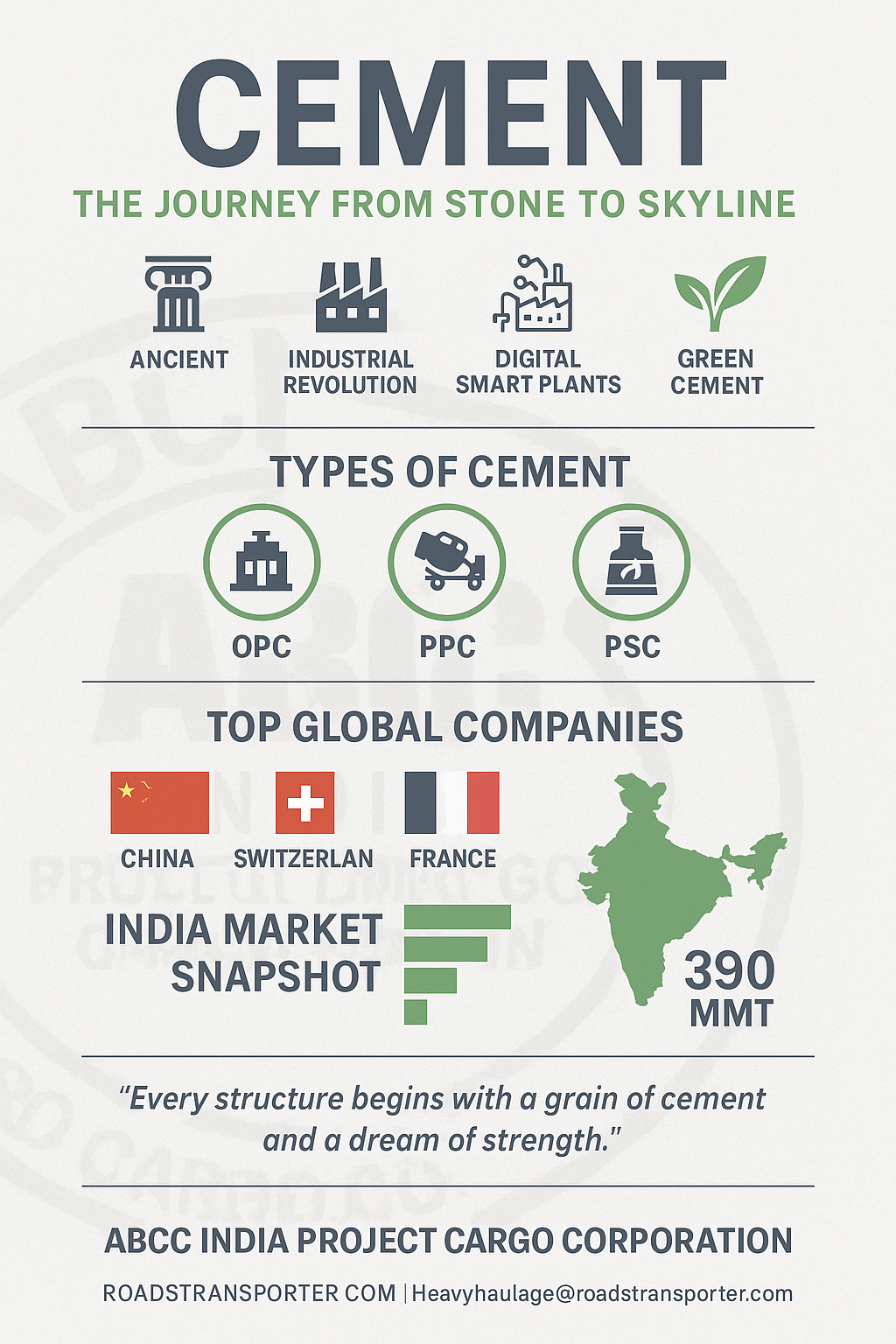

🧾 TYPES OF CEMENT, USES, AND TENTATIVE PRICE RANGE

| Type of Cement | Major Uses | Tentative Price Range (₹/50kg Bag) | Key Features |

|---|---|---|---|

| Ordinary Portland Cement (OPC) | General construction, RCC works, bridges | ₹350–₹450 | High strength, quick setting |

| Portland Pozzolana Cement (PPC) | Residential buildings, plastering, marine works | ₹320–₹420 | Long-lasting, good workability |

| Portland Slag Cement (PSC) | Coastal, sewage, and industrial structures | ₹300–₹400 | High durability, corrosion-resistant |

| Rapid Hardening Cement | Road repairs, precast structures | ₹380–₹460 | Fast strength gain |

| White Cement | Decorative interiors, tiles, sculptures | ₹550–₹750 | High whiteness, smooth finish |

| Sulphate Resistant Cement | Marine foundations, sewage treatment plants | ₹400–₹480 | Sulphate and salt-resistant |

| Low Heat Cement | Dams, large slabs, mass concreting | ₹380–₹450 | Reduced heat during hydration |

| Green Cement / Eco Cement | Sustainable constructions | ₹450–₹550 | Low carbon footprint |

⚙️ CEMENT INDUSTRY MANUFACTURING & PRODUCT LIFECYCLE

The journey of cement from raw rock to the solid foundation beneath our feet is a brilliant example of industrial precision and scientific innovation. The cement manufacturing process is both mechanically powerful and chemically complex, designed to deliver consistency, strength, and sustainability.

Below is the step-by-step breakdown of how the cement industry functions — from raw material to ready product.

🪨 Step 1: Raw Material Extraction

The process begins with limestone, the key ingredient, extracted from quarries through controlled blasting and mining. Clay, silica, iron ore, and gypsum are also sourced. These raw materials are the backbone of cement chemistry.

⚖️ Step 2: Crushing and Grinding

Large stones are crushed using jaw crushers and then ground into fine powder through ball mills or vertical roller mills. This creates a uniform raw mix for the next stage.

🧪 Step 3: Proportioning and Mixing

The powdered materials are mixed in precise ratios (usually 75% limestone and 25% clay/silica) under computer-controlled systems to maintain chemical balance.

🔥 Step 4: The Kiln Phase (Heart of the Process)

The mix enters a rotary kiln, a massive cylindrical furnace reaching 1450°C. Here, chemical reactions form clinker — small, hard nodules that are the true essence of cement.

This phase defines strength, quality, and color.

❄️ Step 5: Cooling and Grinding

The hot clinker is cooled and then ground again with a small percentage of gypsum to control setting time. This final fine powder is what we know as cement.

📦 Step 6: Packaging and Dispatch

Cement is packed in 50 kg bags or bulk containers, loaded onto trucks, rail wagons, or bulk carriers. This is where ABCC India Project Cargo Corporation plays a vital role — moving cement efficiently across the country using its robust heavy-vehicle network.

🔄 Step 7: Product Lifecycle & Quality Development

Cement’s lifecycle doesn’t end at the factory gate. It continues through:

- Quality testing in labs

- Storage and shelf life management

- Application in construction

- End-use monitoring and feedback

This loop ensures every structure built with cement stands as a mark of endurance and precision.

🌍 CEMENT INDUSTRY EVOLUTION (INDIA & GLOBAL)

The global cement industry’s evolution is a story of innovation, economic development, and sustainability. India’s journey, in particular, is a symbol of national progress — where every ton of cement represents the building of homes, schools, and industries.

| Region | Timeline | Key Milestones | Industrial Impact |

|---|---|---|---|

| Ancient Civilizations | 2000 BC – 100 AD | Romans, Greeks, and Egyptians used lime-based mortars | Foundation of early architecture |

| England | 1824 | Joseph Aspdin patents Portland Cement | Birth of modern cement |

| Europe & USA | 1850–1900 | Rotary kilns and mass production | Cement becomes industrial commodity |

| India | 1914 | First cement plant established in Porbandar, Gujarat | Start of Indian cement journey |

| India (Post-Independence) | 1950–1980 | Dams, highways, housing boom | Domestic production growth |

| Global | 1990–2010 | Technological revolution & digital control | Higher efficiency, reduced emissions |

| India (Modern Era) | 2010–Present | Smart plants, green cement, AI-based systems | Sustainability & global recognition |

💰 CEMENT INDUSTRY MARKET SIZE — LOCAL (INDIA) AND GLOBAL

Cement is one of the world’s most consumed materials after water — and its economic value mirrors its importance.

🇮🇳 Indian Market Overview

- India is the 2nd largest producer of cement globally after China.

- Total cement production capacity (2025): 550+ million metric tons (MMT).

- Current market valuation: ₹1.5–₹1.7 lakh crore.

- Annual growth rate (CAGR): 7–8% driven by housing, infrastructure, and rural development.

- Major producing states: Andhra Pradesh, Tamil Nadu, Rajasthan, Gujarat, Chhattisgarh, and Maharashtra.

The Indian cement market is expected to reach ₹2.2 lakh crore by 2030, supported by government schemes like “PM Awas Yojana” and “Smart Cities Mission.”

🌐 Global Market Overview

- Global cement market size (2025): USD 410–430 billion.

- Global production capacity: 4.5–4.8 billion metric tons per annum.

- Top producers: China, India, Vietnam, USA, and Turkey.

- Global CAGR (2024–2030): 5.1%, driven by rapid urbanization and sustainable infrastructure.

- Future trend: Low-carbon cement, green construction, and circular manufacturing models.

🏢 TOP 10 CEMENT MANUFACTURING COMPANIES WORLDWIDE

Below is the structured summary list — full case studies can be generated one by one if you want deep-dive storytelling for each.

| Rank | Company | Headquarter | Global Capacity (MMT) | Leadership Vision | Why Inspiring |

|---|---|---|---|---|---|

| 1 | LafargeHolcim Ltd | Switzerland | 380+ | CEO: Jan Jenisch | Focus on green cement, circular economy, and innovation |

| 2 | Anhui Conch Cement Co. Ltd | China | 350+ | Chairman: Guo Wensan | Largest in Asia, automation pioneer |

| 3 | China National Building Material (CNBM) | China | 330+ | President: Zhou Yuxian | State-backed expansion into Africa & Asia |

| 4 | Heidelberg Materials AG | Germany | 190+ | CEO: Dominik von Achten | Sustainability-focused production |

| 5 | Cemex S.A.B. de C.V. | Mexico | 180+ | CEO: Fernando González | Known for digital cement logistics |

| 6 | Ultratech Cement Ltd | India | 130+ | Chairman: Kumar Mangalam Birla | India’s global cement ambassador |

| 7 | Taiwan Cement Corp | Taiwan | 70+ | CEO: Nelson Chang | Advanced carbon capture technology |

| 8 | CRH Plc | Ireland | 60+ | CEO: Albert Manifold | Mergers-driven global expansion |

| 9 | Votorantim Cimentos | Brazil | 55+ | CEO: Marcelo Castelli | Latin American market leader |

| 10 | Buzzi Unicem SpA | Italy | 45+ | CEO: Pietro Buzzi | Family-driven sustainable cement legacy |

🏭INDIAN STATES – LOCAL BEST CEMENT MANUFACTURERS CHART

| State | Company Name | Owner/Chairman | Experience (Years) | Contact Number | Website | Why Best | Budget/Rate Range (₹/50kg) | |

|---|---|---|---|---|---|---|---|---|

| Andhra Pradesh | Dalmia Cement (Bharat) Ltd | Mahendra Singhi | 80+ | 08645-272500 | [email protected] | dalmiacement.com | Strong coastal logistics, large capacity | ₹340–₹420 |

| Arunachal Pradesh | Valley Cement | T. K. Tsering | 20+ | 03789-223344 | [email protected] | — | Local supplier, eco-friendly | ₹350–₹400 |

| Assam | Topcem Cement | Kailash Chandra Agarwal | 35+ | 0361-2550265 | [email protected] | topcem.in | Dominant NE brand, energy-efficient plant | ₹340–₹410 |

| Bihar | Kalyanpur Cement | S. P. Singh | 40+ | 0612-2538791 | [email protected] | kalyanpurcement.com | Only integrated plant in Bihar | ₹360–₹420 |

| Chhattisgarh | Shree Cement Ltd | H. M. Bangur | 45+ | 07752-240901 | [email protected] | shreecement.com | Major clinker hub, low-cost power | ₹330–₹400 |

| Goa | Zuari Cement Ltd | S. Krishna Kumar | 50+ | 0832-2312323 | [email protected] | zuaricement.com | Efficient port access, durable quality | ₹350–₹420 |

| Gujarat | Ambuja Cements Ltd | Ajay Kapur | 40+ | 079-26427100 | [email protected] | ambujacement.com | Strategic western supply chain | ₹360–₹440 |

| Haryana | JK Lakshmi Cement | Vinita Singhania | 35+ | 0124-4090900 | [email protected] | jklakshmicement.com | Balanced quality & cost | ₹350–₹420 |

| Himachal Pradesh | ACC Cement (Barmana Plant) | Sridhar Balakrishnan | 85+ | 01792-241222 | [email protected] | acclimited.com | Mountain-grade strength, pan-India reach | ₹360–₹430 |

| Jharkhand | Burnpur Cement | Ashok Gutgutia | 25+ | 0651-2401222 | [email protected] | burnpurcement.com | Strong local supply in eastern belt | ₹340–₹400 |

| Karnataka | Vasavadatta Cement | B. K. Birla Group | 45+ | 08472-238002 | [email protected] | vasavadattacement.com | Durable, consistent performance | ₹350–₹420 |

| Kerala | Malabar Cements Ltd | P. A. Salam | 30+ | 0491-2862205 | [email protected] | malabarcements.com | Govt-owned, trusted in southern India | ₹340–₹410 |

| Madhya Pradesh | Prism Cement | Vijay Aggarwal | 35+ | 0761-4044000 | [email protected] | prismcement.com | Centrally located for all-India supply | ₹340–₹420 |

| Maharashtra | Ultratech Cement Ltd | Kumar Mangalam Birla | 40+ | 022-66917800 | [email protected] | ultratechcement.com | India’s largest producer, excellent logistics | ₹370–₹450 |

| Manipur | Birla Uttam Cement | Aditya Birla Group | 25+ | 0385-2441222 | [email protected] | — | Reliable for small infra works | ₹360–₹420 |

| Meghalaya | Star Cement | Sanjay Agarwal | 30+ | 0364-2501040 | [email protected] | starcement.co.in | NE leader, fast-delivery model | ₹340–₹400 |

| Mizoram | Aizawl Cement Works | R. Lalmuana | 15+ | 0389-2332334 | [email protected] | — | Compact unit for local needs | ₹350–₹410 |

| Nagaland | Dimapur Cement Works | K. Temjen | 18+ | 0370-2255333 | [email protected] | — | Local infrastructure supplier | ₹350–₹400 |

| Odisha | OCL India Ltd (Dalmia Group) | Mahendra Singhi | 70+ | 0674-2562020 | [email protected] | oclindia.in | Coastal strength, logistics excellence | ₹340–₹410 |

| Punjab | Ambuja Cements Ltd (Ropar Unit) | Ajay Kapur | 35+ | 01881-220021 | [email protected] | ambujacement.com | High demand in northern corridor | ₹350–₹420 |

| Rajasthan | Wonder Cement Ltd | Vivek Patni | 30+ | 0294-3393300 | [email protected] | wondercement.com | Quality limestone base, modern tech | ₹340–₹430 |

| Sikkim | Sikkim Cement Corp | Karma Bhutia | 15+ | 03592-205222 | [email protected] | — | Local supply and eco-friendly | ₹350–₹410 |

| Tamil Nadu | The India Cements Ltd | N. Srinivasan | 75+ | 044-28521526 | [email protected] | indiacements.co.in | Legacy brand with multiple plants | ₹340–₹430 |

| Telangana | Penna Cement Industries | Prathap Reddy | 30+ | 040-66476700 | [email protected] | pennacement.com | South India bulk leader | ₹340–₹410 |

| Tripura | Tripura Cement Works | A. R. Paul | 20+ | 0381-2323344 | [email protected] | — | Reliable local supplier | ₹340–₹400 |

| Uttar Pradesh | JK Cement Ltd | Madhavkrishna Singhania | 45+ | 0512-2371234 | [email protected] | jkcement.com | North India market leader | ₹350–₹420 |

| Uttarakhand | Century Cement | Aditya Birla Group | 50+ | 0135-2741001 | [email protected] | centurycement.com | High altitude production quality | ₹350–₹430 |

| West Bengal | Ramco Cement Ltd | A. V. Dharmakrishnan | 60+ | 033-22896500 | [email protected] | ramcocement.in | Consistent eastern presence | ₹340–₹420 |

| Delhi (NCT) | ACC Cement Regional Office | Sridhar Balakrishnan | 85+ | 011-23312345 | [email protected] | acclimited.com | Urban distribution & high reliability | ₹370–₹450 |

| Chandigarh | Ambuja Cements Ltd | Ajay Kapur | 35+ | 0172-2620100 | [email protected] | ambujacement.com | Industrial-grade consistency | ₹350–₹430 |

| Jammu & Kashmir | J&K Cement Ltd | Manoj Sharma | 30+ | 0191-2472305 | [email protected] | jkcement.in | Cold-weather resistant cement | ₹340–₹420 |

| Ladakh | Leh Cement Unit | T. D. Namgyal | 12+ | 01982-252222 | [email protected] | — | Local supplier for altitude construction | ₹350–₹420 |

| Andaman & Nicobar | Island Cement | P. S. Subramanian | 18+ | 03192-245677 | [email protected] | — | Small-scale, marine quality | ₹380–₹450 |

| Daman & Diu | Diu Cement Pvt Ltd | H. Mehta | 20+ | 0260-2252345 | [email protected] | — | Coastal blending plant | ₹350–₹410 |

| Puducherry | Chettinad Cement Corp | M. A. M. Ramasamy | 55+ | 0413-2252222 | [email protected] | chettinadcement.com | Trusted southern supplier | ₹340–₹410 |

| Lakshadweep | Kavaratti Cement Traders | Ismail Koya | 10+ | 04896-252323 | [email protected] | — | Island-ready marine quality | ₹380–₹450 |

🇮🇳 TOP 10 INDIAN CEMENT COMPANIES

🥇 1. UltraTech Cement Ltd (Aditya Birla Group)

UltraTech is India’s largest and most respected cement manufacturer, with over 130 million tons capacity and 23 integrated plants. Its visionary leadership under Kumar Mangalam Birla redefined efficiency and sustainability in cement production. The company’s investments in green technology, waste heat recovery systems, and alternative fuels have made it a global model for eco-conscious growth.

From skyscrapers in Mumbai to rural homes in Bihar, UltraTech’s cement forms the foundation of modern India. Its partnership with logistics leaders like ABCC India Project Cargo Corporation ensures reliable and timely transportation of heavy machinery, raw materials, and finished goods across India’s vast terrain. UltraTech represents strength, scale, and sustainability — the three pillars of future infrastructure.

🥈 2. Ambuja Cements Ltd (Holcim Group)

Founded in 1983, Ambuja revolutionized India’s construction industry with its “Building Trust” philosophy. Known for its innovative low-clinker ratio and sustainable manufacturing, Ambuja focuses on green energy, zero-waste goals, and rural housing.

Its logistic efficiency comes from plants in coastal Gujarat, Rajasthan, and Punjab — all interconnected with rail and road logistics managed in partnership with ABCC India. Ambuja’s customer-centric approach, consistent quality, and sustainability initiatives position it as a benchmark in responsible industrialization.

🥉 3. ACC Limited (Holcim Group)

As India’s oldest cement producer (established 1936), ACC has been part of India’s growth story for nearly a century. It played a crucial role in building iconic structures like dams, airports, and metro projects.

Its Barmana Plant (Himachal Pradesh) is globally recognized for its energy-efficient rotary kilns. ACC’s continuous modernization and human-centric management have earned it the title of “the cement with conscience.”

🏗️ 4. Shree Cement Ltd

A name synonymous with performance and profitability, Shree Cement is known for operational excellence. Based in Rajasthan, it runs fully automated plants and produces over 50 million tons per annum.

Its innovation in low power consumption per ton makes it one of the most efficient producers in the world. The company’s regional strength and strategic alliances with logistics providers like ABCC India make it a preferred supplier across northern and eastern India.

🏛️ 5. Dalmia Cement (Bharat) Ltd

Established in 1939, Dalmia Cement’s vision is to “Rebuild India.” Its blend of traditional ethics and modern engineering makes it a unique force. The company produces Green Cement, a low-carbon variant, and has pledged to become carbon-negative by 2040.

ABCC India supports Dalmia’s pan-India dispatch network by transporting massive industrial machinery, kilns, and clinker units, ensuring uninterrupted production cycles.

🌿 6. Ramco Cements Ltd

Headquartered in Chennai, Ramco Cements is renowned for its clean energy usage and customer-first approach. Its strength lies in precision technology and eco-friendly products.

The brand dominates South India’s housing market and continues expanding across Maharashtra and Odisha, leveraging ABCC’s multi-modal freight connectivity for reliable distribution.

🧱 7. The India Cements Ltd

A legacy company founded in 1946, it’s one of India’s oldest private cement firms. Known for reliability and integrity, it played a pivotal role in nation-building post-independence.

Its dynamic logistics integration with ABCC India ensures raw material and finished cement movement across multiple ports and plants.

🌏 8. JK Cement Ltd

JK Cement, a leading producer of white and grey cement, has gained international fame with exports to 30+ countries. Its “People-First and Quality Forever” motto drives continuous innovation.

With ABCC’s heavy-haul logistics, JK Cement expands reach to remote areas, reinforcing India’s infrastructure backbone.

🧩 9. Wonder Cement Ltd

A relatively new but powerful entrant, Wonder Cement embodies young India’s energy. Based in Rajasthan, it uses advanced German technology (Thyssenkrupp) for consistent quality.

It has grown exponentially due to its “trust and transparency” policy — values shared with ABCC India Project Cargo Corporation.

🔰 10. Penna Cement Industries Ltd

Penna Cement from Telangana is one of India’s fastest-growing cement groups, serving both domestic and export markets. Known for bulk cement and port-based plants, Penna relies heavily on multi-modal transport and efficient project cargo handling, often managed through ABCC’s logistic expertise.

🕰️ BEST ERA AND RECESSION PERIODS FOR THE CEMENT INDUSTRY

Every industry experiences cycles of growth and slowdown, and the cement industry is no exception. What sets it apart is its resilience — its ability to rise stronger after every phase of recession.

🌅 Best Era — The Golden Period (1995–2012)

Between 1995 and 2012, the global cement industry witnessed one of its most prosperous eras. Rapid urbanization, infrastructure spending, and housing development in emerging nations like India, China, and Brazil created unprecedented demand.

India, in particular, saw its annual production jump from 70 MMT to 240 MMT in just 15 years. Mega projects like highways, metro systems, and industrial zones drove exponential growth.

Cement companies reinvested profits into new rotary kilns, digital control systems, and logistics partnerships, reducing operational cost and improving supply efficiency. This was also when ABCC India Project Cargo Corporation expanded its heavy cargo logistics fleet — enabling faster plant expansions and raw material movements across the country.

🌧️ Recession Period — The Slowdown Years (2013–2015 & 2020 Pandemic)

The 2013–2015 period brought temporary turbulence caused by overproduction, high energy costs, and global economic contraction.

A second significant slowdown hit in 2020 during the COVID-19 pandemic, when construction activity almost halted globally. Demand declined by 25–30%, and logistics were disrupted.

However, the industry rebounded rapidly post-pandemic with the Make-in-India mission, Smart City Projects, and government investment in rural infrastructure.

Cement once again proved its strength — breaking through the walls of economic uncertainty.

🌿 ENVIRONMENTAL EFFECTS & SEASONAL IMPACT ON THE CEMENT INDUSTRY

Cement manufacturing is energy-intensive, but the modern era is rewriting that narrative with sustainability at its core.

🌎 Environmental Effects

Cement production contributes about 7–8% of global CO₂ emissions, primarily from the kiln’s high-temperature process. However, manufacturers are adopting waste heat recovery systems, solar energy, and low-carbon alternatives to minimize their footprint.

Many Indian companies like Dalmia Cement, Ultratech, and Ambuja are now aligning with the Paris Climate Agreement, targeting net-zero emissions by 2050.

☀️ Seasonal Impact

- Monsoon Season (June–September): Demand declines due to reduced construction activity, especially in housing.

- Winter Season (Nov–Feb): Peak consumption for infrastructure and real estate.

- Summer Season (Mar–May): Stable but heat-sensitive logistics period; higher transport costs.

This seasonal cycle creates an opportunity for logistics companies like ABCC India to manage flexible scheduling, bulk dispatches, and warehouse optimization.

🏛️ CEMENT INDUSTRY UNIONS AND AUTHORITIES — INDIA & GLOBAL

| Region | Association / Authority | Headquarters | Role / Function | Contact Info |

|---|---|---|---|---|

| India | Cement Manufacturers’ Association (CMA) | New Delhi | Policy advocacy, quality standards, sustainability | [email protected] |

| India | Bureau of Indian Standards (BIS) | New Delhi | Quality certification & IS codes for cement | [email protected] |

| India | Ministry of Heavy Industries | New Delhi | Industrial policy & modernization support | [email protected] |

| Global | World Cement Association (WCA) | London, UK | International collaboration & emission policy | [email protected] |

| Global | Global Cement and Concrete Association (GCCA) | Geneva, Switzerland | Climate action and innovation sharing | [email protected] |

| Asia | ASEAN Cement Producers Network | Bangkok | Regional trade support and industrial partnerships | [email protected] |

⚖️ ADVANTAGES AND DISADVANTAGES OF THE CEMENT INDUSTRY

| Advantage | Description | Disadvantage | Description |

|---|---|---|---|

| Backbone of infrastructure | Cement enables highways, bridges, and housing | High energy consumption | Kilns require large fuel input |

| Employment generation | Millions of direct and indirect jobs | Pollution impact | CO₂ and dust emissions |

| Economic multiplier | Boosts steel, transport, and construction sectors | Seasonal demand | Rain and climate slowdowns affect production |

| Export potential | Indian brands serve 30+ countries | Overcapacity issues | Supply often exceeds demand |

| Durable product | Long lifespan of structures | Raw material depletion | Continuous mining of limestone |

| Technological advancement | Automation and AI adoption | Logistics cost sensitivity | Freight cost fluctuations affect margins |

📜 LEGAL & COMPLIANCE FRAMEWORK (LOCAL AND GLOBAL)

| Country/Region | Key Regulation | Quality Standards | Certification Bodies |

|---|---|---|---|

| India | Cement (Quality Control) Order, 2003 | IS 269, IS 1489, IS 455, IS 12330 | BIS – Bureau of Indian Standards |

| India | Air (Prevention & Control of Pollution) Act, 1981 | Environmental norms for kilns | CPCB & SPCBs |

| Global | ASTM Standards (USA) | ASTM C150, C595 | ASTM International |

| Europe | EN 197 Standard | EN 197-1:2011 | European Committee for Standardization (CEN) |

| ISO Global | ISO 9001 / 14001 | Quality & environmental management | ISO Organization |

| GCC (Middle East) | SASO / GSO Regulations | Construction quality standards | Gulf Standards Organization |

| Africa | SON (Nigeria) / SABS (South Africa) | Localized quality certification | Regional quality councils |

⚡ LEGAL COMPLIANCE AND QUALITY CERTIFICATIONS EXPLAINED

Every cement manufacturer must comply with national and international standards to ensure product strength, safety, and environmental protection.

In India, mandatory certification under BIS IS 269 for Ordinary Portland Cement and IS 1489 for Pozzolana variants ensures quality integrity.

Globally, organizations like ASTM and EN regulate composition, fineness, and compressive strength testing.

Compliance is not just a legal necessity — it’s a symbol of trust and industrial credibility. ABCC India Project Cargo Corporation proudly associates with certified and compliant manufacturers, ensuring safe, ethical, and efficient logistics support nationwide.

🇮🇳 INDIA & GOVERNMENT ROLE IN THE CEMENT AND ENERGY INDUSTRY

The Government of India plays a vital role in shaping the future of the cement and energy industries, recognizing them as the pillars of national infrastructure growth.

Cement is not merely a construction material—it’s a development indicator. Every kilometer of highway, every metro track, and every rural home echoes the sound of India’s industrial progress.

To promote sustainability and self-reliance, the government launched multiple schemes and policies that revolutionized the sector:

- Make in India: Encouraged domestic manufacturing, reduced import dependency, and pushed global competitiveness.

- National Infrastructure Pipeline (NIP): ₹111 lakh-crore investment plan fueling roads, ports, housing, and industrial corridors.

- Energy Efficiency Mission (PAT Scheme): Reduced energy consumption per ton of cement.

- Green Energy Policy 2025: Promotes alternate fuels, waste heat recovery, and solar integration.

- GST Simplification: Unified taxation system boosting logistics efficiency.

The government’s vision aligns with ABCC India Project Cargo Corporation’s mission—connecting industries through cost-effective, safe, and nationwide heavy-haul logistics.

🏬 CEMENT INDUSTRY HUBS AND BIG MARKETS IN INDIA (BY SEASON)

| Region | Major Cement Hub / Market | Season of Peak Demand | Key Infrastructure Projects | Industrial Significance |

|---|---|---|---|---|

| North India | Rajasthan, Haryana, Punjab | Winter (Nov–Feb) | Expressways, industrial parks | High per-capita consumption |

| West India | Gujarat, Maharashtra | All year | Ports, housing, industrial belts | Export gateway and port logistics |

| South India | Tamil Nadu, Andhra Pradesh, Telangana | Summer (Mar–May) | Housing, wind-energy towers | Strong production base |

| East India | Chhattisgarh, Odisha, West Bengal | Monsoon recovery (Aug–Oct) | Mining, steel plants | Upcoming cement corridor |

| Central India | Madhya Pradesh, Uttar Pradesh | Winter–Spring | Metro & housing projects | Balanced consumption zone |

| North-East India | Assam, Meghalaya | Dry season (Oct–Apr) | Border infra & road projects | Strategic regional growth |

India’s cement geography perfectly complements ABCC India’s pan-India logistics network, enabling real-time coordination and cost-effective heavy-cargo movement.

🪨 CEMENT INDUSTRY — MOST SELLING ITEMS & RAW MATERIAL SUPPLIER CHART

| Raw Material | Major Use | Big Supplier / Source | Tentative Price Range | Supply Location |

|---|---|---|---|---|

| Limestone | Primary raw material | UltraTech Mines, Dalmia Mines | ₹500–₹700 / ton | Rajasthan, MP, Chhattisgarh |

| Gypsum | Setting agent | Rajasthan State Mines | ₹1,000–₹1,400 / ton | Rajasthan |

| Fly Ash | Pozzolanic additive | NTPC Power Stations | ₹400–₹600 / ton | Pan-India |

| Coal / Petcoke | Fuel for kilns | Coal India Ltd | ₹6,000–₹9,000 / ton | Jharkhand, Chhattisgarh |

| Iron Ore | Ingredient for strength | NMDC Ltd | ₹4,500–₹6,000 / ton | Odisha, Karnataka |

| Slag | Additive in PSC cement | Tata Steel & JSW | ₹1,000–₹1,500 / ton | Odisha, Maharashtra |

| Packing Material | Cement bags | Birla Packaging Ltd | ₹15–₹20 / bag | Pan-India |

| Refractory Bricks | Kiln lining | Orient Refractories | ₹35,000–₹40,000 / ton | Rajasthan |

| Transportation | Logistics of materials | ABCC India Project Cargo Corp | ₹2–₹4 / ton-km | All India |

📈 MARKET TRENDS & GROWTH DRIVERS

The cement industry is entering a new age of digital industrialization. Several forces are steering this evolution:

- Sustainability First: Transition to green cement and renewable fuels.

- Smart Plants: AI and IoT controlling kiln efficiency, reducing energy losses.

- Affordable Housing Boom: Government housing schemes spiking domestic demand.

- Infrastructure Expansion: National Highway projects and smart city frameworks.

- Export Potential: India emerging as a key supplier to Africa and Southeast Asia.

- Logistics Revolution: Multi-modal transport (road, rail, coastal shipping) led by ABCC India’s freight capabilities.

Together, these trends ensure that the next decade belongs to resilient, responsible, and re-engineered cement producers.

🧩 INDIAN REGULATORY CHANGES AND INDUSTRY FORECAST

- 2024–2025: New emission standards introduced by CPCB.

- 2026–2028: Wider implementation of green cement certifications.

- 2030 Forecast: Indian production expected to cross 700 million tons with a CAGR of 7.5%.

- Global Outlook: Expected market size USD 550 billion by 2030, driven by Africa and Asia.

The cement-logistics ecosystem, powered by players like ABCC India Project Cargo Corporation, will remain critical to managing raw material inflows and dispatch cycles.

🤝 KEY STAKEHOLDERS IN THE CEMENT INDUSTRY

| Stakeholder | Role | Impact |

|---|---|---|

| Manufacturers | Production & innovation | Drive market supply |

| Logistics Providers | Transportation of materials and products | Ensure smooth supply chain |

| Government Bodies | Policy & regulation | Maintain quality and compliance |

| Investors & Financial Institutions | Funding expansions | Enable capacity growth |

| Construction Companies | End users | Shape real-world demand |

| Workforce & Unions | Labour & welfare | Maintain ethical growth balance |

| Environmental Agencies | Monitoring emissions | Drive sustainability goals |

🚧 CHALLENGES, SOLUTIONS, AND INNOVATIONS

Challenges:

- High energy and freight costs.

- Raw material availability fluctuations.

- Carbon emission pressure.

- Overcapacity in regional markets.

Solutions:

- Energy-efficient rotary kilns.

- Alternative fuels (biomass, waste heat).

- Logistics optimization through ABCC India’s multi-modal approach.

- Digital automation and predictive maintenance.

Innovations:

- 3D printed concrete.

- Carbon-capture cement technology.

- Green certification mechanisms.

🚢 WAREHOUSING, SUPPLY CHAIN & MULTI-MODAL LOGISTICS IN CEMENT INDUSTRY

The success of any cement company depends on how efficiently it moves its product.

Here, ABCC India Project Cargo Corporation plays a defining role—offering road, rail, and coastal logistics integration for raw materials, heavy machinery, and finished products.

From moving kilns, silos, conveyors, and plant machinery to handling bulk cement dispatch across states, ABCC India stands as the trusted logistics backbone of the nation’s cement industry.

Its value proposition includes:

- 🚛 On-time multi-axle and hydraulic trailer support

- ⚙️ End-to-end route and load optimization

- 🏗️ Specialized ODC and project cargo expertise

- 🕒 Real-time tracking and GPS monitoring

- 💰 Cost-optimized freight management

💸 TAXATION IMPACT — DOMESTIC & GLOBAL CEMENT BUSINESS

India’s GST regime (28%) on cement remains one of the highest among construction materials. While it streamlines operations, it increases final construction cost.

Globally, tax ranges between 12–20%, making Indian exports slightly less competitive.

Government’s Future Plan: Introduce differentiated tax slabs for eco-friendly “Green Cement.”

This move will encourage low-carbon innovation and attract FDI in sustainable construction.

ABCC India’s efficient logistics helps manufacturers offset taxation effects by reducing freight cost per ton-km—maintaining profitability despite higher GST.

🔮 FUTURE OF THE CEMENT MANUFACTURING INDUSTRY

The cement industry’s next decade will be marked by AI-powered plants, decarbonization, and smart construction integration.

By 2035, India aims to become the world’s largest sustainable cement producer, blending industrial growth with environmental ethics.

Future trends include:

- Digital twins for plant management

- Hydrogen-fuel-based kiln operations

- Net-zero plants by 2040

- Smart logistics corridors led by ABCC India Project Cargo Corporation

The future of cement will not be grey—it will be green, intelligent, and inspirational.

🧱 CEMENT MANUFACTURING INDUSTRY SUMMARY AND CONCLUSION

Cement has travelled a long road—from ancient Roman binders to modern AI-driven smart factories. It symbolizes strength, endurance, and ambition.

In India, this industry powers not only infrastructure but also the dreams of millions who build homes, roads, and industries with it.

ABCC India Project Cargo Corporation, with its unmatched experience in heavy cargo movement and nationwide reach, stands shoulder-to-shoulder with the cement industry.

Its mission is simple yet profound — “Transporting Strength, Delivering Trust.”

From quarry to kiln, from factory to foundation — ABCC India ensures that every ton of cement moves efficiently, safely, and sustainably.

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

Peb Enginieering Association :- www.pessi.in

Indian Steel Association :- www.indsteel.org

Builders Association of India :- www.baionline.in

Indian Stainless Steel Development Association (ISSDA) :- www.stainlessindia.org

Cement Manufacturers Association (CMA) :- www.cmaindia.org