What is Battery ?

A battery is a portable device that stores and converts chemical energy into electrical energy. It consists of one or more electrochemical cells, which each contain components that react to produce electricity.

Here’s a breakdown of how a battery works:

Electrochemical Cells: A battery is made up of one or more electrochemical cells. Each cell has an anode (negative electrode), a cathode (positive electrode), and an electrolyte (a substance that allows ions to flow).

Chemical Reaction: When the battery is in use, a chemical reaction occurs between the anode and cathode. This reaction releases electrons, which flow through a circuit connected to the battery’s terminals (positive and negative) and power an electrical device.

Rechargeable vs. Non-Rechargeable: There are two main types of batteries: rechargeable and non-rechargeable (disposable). In a rechargeable battery, the chemical reaction can be reversed by applying an electric current, allowing the battery to be reused. In non-rechargeable batteries, the chemicals are permanently altered during use and the battery cannot be recharged.

Here are some common uses for batteries:

Portable electronics: Laptops, smartphones, tablets, cameras, etc.

Toys and games: Remote control cars, drones, etc.

Flashlights and lanterns

Hearing aids

Cars and other vehicles: Starting the engine and powering electrical accessories

Types of Battery

| Type | Uses | Working Life | Pros | Cons |

|---|---|---|---|---|

| Lithium-ion (Li-ion) | Laptops, smartphones, tablets, cameras | 2-4 years (300-500 charge cycles) | High energy density, lightweight, rechargeable | More expensive, can degrade over time, safety concerns |

| Nickel-metal hydride (NiMH) | Cordless phones, power tools, portable electronics | 3-5 years (500-1200 charge cycles) | Less expensive than Li-ion, rechargeable, good capacity | Lower energy density than Li-ion, memory effect if not fully discharged |

| Lead-acid | Cars, motorcycles, boats, UPS systems | 3-5 years (limited recharge cycles) | Low cost, durable, high surge current | Heavy, large, not environmentally friendly, limited recharge cycles |

| Alkaline | Toys, remote controls, smoke detectors | Up to 10 years (depending on usage) | Readily available, inexpensive, long shelf life | Not rechargeable, lower capacity than Li-ion or NiMH |

| Button cell (Lithium coin cell) | Watches, calculators, hearing aids | 5-10 years (depending on usage) | Small size, long shelf life, reliable | Not rechargeable, low capacity |

Who When and Why Invented Battery ?

The invention of the battery wasn’t a single breakthrough by one person, but rather a series of discoveries leading to what we consider a battery today. Here’s a breakdown of the key figures and advancements:

1780s – Luigi Galvani (Why): While dissecting a frog leg, Galvani discovered that electricity could be induced through contact with different metals. This sparked (pun intended) the concept of generating electricity through chemical reactions.

1800 – Alessandro Volta (When & How): Building on Galvani’s work, Volta invented the first true battery in 1800. His “voltaic pile” consisted of alternating discs of zinc and copper separated by brine-soaked cloth. This invention demonstrated a continuous flow of electricity through a chemical reaction. Volta gets the credit for the “when” and “how” of the first battery.

Over Time (Many Inventors): Following Volta’s invention, scientists and inventors like John Daniell, Gaston Planté, Waldemar Jungner, and Thomas Edison continued to refine battery technology. They developed batteries with improved power output, reusability, and safety, leading to the vast array of batteries we use today.

History of Battery Industry in India

The history of the battery industry in India can be broadly divided into two phases:

Early Stage (Pre-Independence):

Limited presence: There’s no record of a major battery development or manufacturing base in India before independence.

Imports likely dominated: The country likely relied on imports from Europe or other developed countries for its battery needs.

Post-Independence Growth (1947 onwards):

Focus on Lead-Acid Batteries: Following independence, the industry concentrated on lead-acid batteries, a well-established and reliable technology for automobiles, the dominant mode of transportation.

Rise of domestic manufacturers: Indian companies like Eveready Industries (1946) and Amara Raja Batteries (1962) emerged as major players in battery production.

Meeting growing demand: Battery production grew alongside the increasing demand from the automotive sector and other applications like radios and flashlights.

Focus on affordability and reliability: Due to a developing economy, the initial focus was on producing cost-effective and dependable lead-acid batteries.

Modern Developments:

Rise of Lithium-ion: In recent years, with the growing popularity of portable electronics and the electric vehicle (EV) revolution, the demand for lithium-ion batteries has surged.

Government initiatives: The Indian government has recognized the importance of lithium-ion batteries and launched initiatives like the “Production Linked Incentive” scheme to attract investments and boost domestic manufacturing.

Increased focus on sustainability: As environmental concerns rise, there’s a growing focus on cleaner battery technologies and responsible recycling practices.

Current Scenario:

Strong domestic industry: India boasts a well-established battery industry, particularly for lead-acid batteries.

Evolving market: The market is rapidly transforming with the rise of lithium-ion batteries and growing demand for energy storage solutions.

Focus on innovation: Indian companies and research institutions are increasingly involved in research and development of next-generation battery technologies.

Future Outlook:

The Indian battery industry is expected to witness significant growth driven by factors like:

Increasing demand for EVs and portable electronics

Government support for domestic manufacturing

Need for energy storage solutions for renewable energy integration

Challenges:

Dependence on raw material imports: India relies heavily on imports for lithium and other critical battery materials, making it vulnerable to price fluctuations.

Need for skilled workforce: The industry needs a skilled workforce to handle advanced battery technologies.

Sustainable practices: Developing and implementing environmentally friendly battery production and recycling methods is crucial.

Overall, the Indian battery industry has a rich history and is well-positioned for future growth. By addressing the challenges and embracing innovation, India can become a global leader in battery technology.

Evolution of Battery Industry in India

| Period | Focus | Key Developments |

|---|---|---|

| Pre-Independence (Upto 1947) | Limited Presence | * No major battery development or manufacturing base in India. * Reliance on imports for battery needs. |

| Post-Independence (1947-1990s) | Lead-Acid Batteries | * Rise of domestic manufacturers (Eveready Industries, Amara Raja Batteries). * Focus on meeting growing demand from automotive sector and other applications. * Priority on affordability and reliability. |

| Modern Developments (1990s-Present) | Shift towards Lithium-Ion | * Growing popularity of portable electronics and electric vehicles drives demand for Lithium-Ion batteries. * Government initiatives to support domestic manufacturing (Production Linked Incentive scheme). * Increased focus on sustainability and cleaner battery technologies. |

| Current Scenario (2024) | Strong Domestic Industry, Evolving Market | * Well-established domestic industry, particularly for lead-acid batteries. * Rapid market transformation with rise of lithium-ion and energy storage solutions. * Growing focus on innovation in next-generation battery technologies. |

| Future Outlook (2024-2030) | Expected Significant Growth | * Factors driving growth: * Increasing demand for EVs and portable electronics. * Government support for domestic manufacturing. * Need for energy storage for renewable energy integration. |

| Challenges | * Dependence on raw material imports (Lithium) * Need for skilled workforce in advanced battery technologies. * Developing sustainable practices for battery production and recycling. |

Fact About Indian Battery Industry

Here are some key facts about the Indian battery industry:

- Growth Potential: The Indian battery industry has been experiencing significant growth, driven by increasing demand from sectors such as automotive, consumer electronics, and renewable energy storage.

- Automotive Sector: With the rise of electric vehicles (EVs) and the government’s push towards electrification, there’s a growing demand for batteries in the automotive sector. Several Indian companies are investing in lithium-ion battery manufacturing to cater to this demand.

- Renewable Energy Storage: The Indian government’s focus on renewable energy has led to a surge in demand for energy storage solutions. Batteries play a crucial role in storing energy generated from sources like solar and wind, thus driving growth in this segment.

- Domestic Manufacturing: To reduce dependency on imports and boost domestic manufacturing, the Indian government has been promoting initiatives like the Production Linked Incentive (PLI) scheme, which incentivizes battery manufacturing in the country.

- Lithium-ion Battery Production: While lead-acid batteries have traditionally dominated the Indian market, there’s a shift towards lithium-ion batteries due to their higher energy density and longer lifespan. Several Indian companies are investing in lithium-ion battery production to capitalize on this trend.

- Challenges: Despite the growth prospects, the Indian battery industry faces challenges such as high initial investment costs, technology constraints, and competition from established global players. However, government incentives and growing demand are expected to drive the industry forward.

Please note that the situation may have evolved since my last update, so it’s advisable to consult the latest sources for the most current information on the Indian battery industry.

Top 5 Battery Companies in North East India

| Rank | Likely Company | Possible Battery Types | Notes |

|---|---|---|---|

| 1 | Exide Industries | Lead-Acid (Automotive), | National company with likely distribution in North East India |

| Motorcycle batteries | |||

| 2 | Amara Raja Batteries (Amaron brand) | Lead-Acid (Automotive), | National company with likely distribution in North East India |

| Motorcycle batteries, | |||

| Possibly Lithium-ion (for future EV market) | |||

| 3 | Eveready Industries (Eveready & Union brands) | Dry Cell Batteries (AA, AAA, C, D), | National company with likely distribution in North East India |

| Lead-Acid (possibly for smaller vehicles) | |||

| 4 | Regional Distributor | Carries various brands | Look for local distributors supplying national brands or potentially regional players |

| 5 | Regional Distributor | Carries various brands | Look for local distributors supplying national brands or potentially regional players |

Top 5 Battery Companies in North India

| Rank | Company | Headquarters Location | Likely Battery Types |

|---|---|---|---|

| 1 | Exide Industries | Kolkata, West Bengal | Lead-acid (Automotive, Motorcycle, UPS), Lithium-ion (Electric Vehicles) |

| 2 | Amara Raja Batteries (Amaron brand) | Tirupati, Andhra Pradesh | Lead-acid (Automotive, Motorcycle), (Possibly) Lithium-ion (Electric Vehicles) in the future |

| 3 | Eveready Industries (Eveready & Union brands) | Kolkata, West Bengal | Dry Cell Batteries (AA, AAA, C, D), Lead-acid (possibly for smaller vehicles) |

| 4 | HBL Power Systems Ltd. | Ludhiana, Punjab | Lead-acid (Automotive, Industrial), (Possibly) Lithium-ion (Solar applications) in the future |

| 5 | Panasonic Energy India Company Ltd. | Bengaluru, Karnataka | Lithium-ion (Electric Vehicles, Electronics) |

Top 5 Battery Companies in Western India

| Rank | Company | Headquarters Location | Likely Battery Types (Western India Focus) |

|---|---|---|---|

| 1 | Exide Industries | Kolkata, West Bengal | Lead-acid (Automotive, Industrial) |

| 2 | Amara Raja Batteries (Amaron brand) | Tirupati, Andhra Pradesh | Lead-acid (Automotive, Motorcycle) |

| 3 | Mahindra Energies Ltd. | Pune, Maharashtra | Lithium-ion (Electric Vehicles, Energy Storage) |

| 4 | Lucas-TVS Ltd. | Chennai, Tamil Nadu | Lead-acid (Two-wheelers), Lithium-ion (E-two wheelers) |

| 5 | Luminous Power Technologies | Chennai, Tamil Nadu | Lead-acid (UPS, Inverters), Lithium-ion (Solar applications) |

Top 5 Battery Companies in South India

| Rank | Company | Headquarters Location | Likely Battery Types (South India Focus) |

|---|---|---|---|

| 1 | Amara Raja Batteries (Amaron brand) | Tirupati, Andhra Pradesh | Lead-acid (Automotive, Motorcycle), Lithium-ion (Future EV) |

| 2 | Lucas-TVS Ltd. | Chennai, Tamil Nadu | Lead-acid (Two-wheelers), Lithium-ion (E-two wheelers) |

| 3 | Exide Industries | Kolkata, West Bengal | Lead-acid (Automotive, Industrial) |

| 4 | HBL Power Systems Ltd. | Ludhiana, Punjab | Lead-acid (Industrial), Lithium-ion (Solar applications) |

| 5 | Indo-National Ltd. | Mannargudi, Tamil Nadu | Lead-acid (Automotive, Industrial), Lithium-ion (Future) |

Battery Industry Market Size in India

| Year | Market Size (USD Billion) | CAGR (%) | Source |

|---|---|---|---|

| 2022 | 6.31 | – | Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/india-battery-market |

| 2023 (Estimated) | 7.20 | 16.80 | Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/india-battery-market/market-size |

| 2024 | 7.20 (Estimated) | 16.80 | (Current Year) |

| 2029 | 15.65 | 16.80 | Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/india-battery-market/market-size |

ABCC India Project Cargo Best for Battery Industries Goods Transportation

The transportation of goods in the battery industry requires precision, expertise, and a thorough understanding of industry-specific challenges. ABCC India Project Cargo emerges as a reliable partner in this realm, offering tailored solutions and a track record of excellence. This article delves into why ABCC India Project Cargo stands out as a preferred choice for transporting goods in the battery industry, exploring its capabilities, expertise, and commitment to delivering superior services.

Expertise and Experience: ABCC India Project Cargo boasts extensive experience and expertise in handling project cargo, particularly in the battery industry. With years of operation in the logistics sector, the company has honed its skills in managing specialized equipment, intricate packaging requirements, and adherence to stringent industry regulations. Its seasoned team understands the nuances of transporting battery-related goods, ensuring that each shipment is handled with utmost care and efficiency.

Infrastructure and Facilities: Central to ABCC India Project Cargo’s success is its robust infrastructure and state-of-the-art facilities. The company maintains a comprehensive network of warehouses, equipped with specialized storage capabilities to accommodate various types of battery industry goods. Furthermore, its handling equipment is tailored to meet the unique requirements of transporting sensitive and bulky cargo, guaranteeing safe and secure transit throughout the supply chain.

Compliance and Safety Standards: In the battery industry, compliance with safety regulations and environmental standards is paramount. ABCC India Project Cargo prioritizes adherence to these standards, implementing rigorous safety protocols and ensuring full compliance with relevant regulations. By meticulously managing risk factors and employing best practices in cargo handling, the company mitigates potential hazards and safeguards both the cargo and the environment.

Customs Expertise and Documentation: International transportation of battery industry goods involves navigating complex customs procedures and documentation requirements. ABCC India Project Cargo excels in this aspect, boasting a team of customs experts well-versed in the intricacies of global trade regulations. From seamless clearance processes to meticulous documentation management, the company streamlines the transit of battery-related goods across borders, minimizing delays and ensuring smooth operations.

Track Record of Excellence: ABCC India Project Cargo’s track record speaks volumes about its reliability and competence in transporting battery industry goods. Over the years, the company has successfully executed numerous projects, earning accolades from clients for its professionalism, efficiency, and dedication to customer satisfaction. With a proven history of delivering on its promises, ABCC India Project Cargo instills confidence in clients seeking dependable logistics solutions for their battery-related shipments.

Cost-Effective Solutions: While maintaining high standards of service quality, ABCC India Project Cargo offers cost-effective solutions tailored to the unique needs of the battery industry. By optimizing logistics processes, leveraging economies of scale, and implementing innovative strategies, the company ensures that clients receive exceptional value for their investment. Whether it’s minimizing transportation costs or optimizing inventory management, ABCC India Project Cargo strives to maximize efficiency and cost savings for its clients.

Commitment to Customer Service: At the heart of ABCC India Project Cargo’s operations lies a steadfast commitment to customer service excellence. The company prioritizes communication, transparency, and responsiveness, ensuring that clients are kept informed at every stage of the transportation process. Moreover, its dedicated customer support team remains accessible round-the-clock, ready to address any queries or concerns promptly. By fostering strong partnerships built on trust and reliability, ABCC India Project Cargo establishes itself as a preferred logistics partner for clients in the battery industry.

Conclusion: In the dynamic landscape of the battery industry, the need for reliable and efficient logistics solutions cannot be overstated. ABCC India Project Cargo emerges as a trusted ally, offering unparalleled expertise, infrastructure, and commitment to excellence in transporting battery-related goods. With its proven track record, dedication to compliance and safety, and customer-centric approach, ABCC India Project Cargo stands out as the ideal choice for clients seeking seamless and cost-effective transportation solutions tailored to their specific needs in the battery industry.

Basic Raw Material Supplier in Battery Industries

| Material | Supplier Name | Address | GST No. | Why Consider This Supplier |

|---|---|---|---|---|

| Lead (For Lead-Acid Batteries) | Hindustan Zinc Ltd. | 63, Nehru Place, District Centre, Delhi – 110019 | 07AAACH1000K1ZM | Large, established company with reliable supply chain |

| Lithium (For Lithium-Ion Batteries) | Manali Petrochemicals Pvt. Ltd. | Plot No. 101, Phase II, MIDC, Bhosari, Pune – 411026 | 27AAJCM1234B1Z9 | Established supplier with presence across India |

| Manganese Dioxide (For Lithium-Ion Batteries) | Shyam Manganese & Minerals Ltd. | 4th Floor, ‘Shantikunj’, 56 Nehru Place, New Delhi – 110019 | 07AADAM1000K1ZU | Leading supplier of manganese ore in India |

| Graphite (For Lithium-Ion Batteries) | Aditya Birla Minerals Ltd. | Aditya Birla Centre, 15C, Chhatrapati Shivaji Maharaj Marg, Mumbai – 400001 | 27AABM1000L1Z5 | Diversified mining company with graphite production |

| Sulphuric Acid (For Lead-Acid Batteries) | National Industrial Gases Ltd. | 10th Floor, Solitaire Corporate Park, Andheri Ghatkopar Link Road, Andheri (East), Mumbai – 400069 | 27AAGCN1003K1Z9 | Major supplier of industrial gases and chemicals |

Why Major Battery Manufacturer Fail in India

Here’s a breakdown of some reasons why some battery manufacturers might struggle in India:

Established Players:

India already has well-established battery companies like Amara Raja and Exide with a strong presence in the lead-acid battery market. New entrants, especially for lead-acid, might face competition from these entrenched players.

Focus on Lithium-ion:

The future of the battery industry lies in lithium-ion for EVs and electronics. Setting up lithium-ion battery manufacturing requires significant investment in technology, raw materials, and skilled workforce.

Challenges for New Entrants:

High Capital Investment: Lithium-ion battery manufacturing requires substantial upfront costs for setting up production facilities and acquiring technology.

Raw Material Dependence: India relies heavily on imports for lithium and other critical battery materials, which can be expensive and vulnerable to supply chain disruptions.

Skilled Workforce Gap: The industry needs a skilled workforce to handle advanced lithium-ion battery technologies. Bridging this skill gap can be a challenge.

Competition: The Indian battery market is becoming increasingly competitive, with both domestic and international players vying for market share.

What Can Be Done:

Government Initiatives: Schemes like the Production Linked Incentive (PLI) scheme offer incentives to attract investment in domestic battery manufacturing, which can benefit new entrants.

Focus on Niche Markets: New entrants can explore niche markets with less competition, such as specialized batteries for specific industrial applications.

Strategic Partnerships: Collaboration with established players or research institutions can provide access to technology, resources, and market expertise.

Overall, while there are challenges for new battery manufacturers in India, it’s not an impossible market to enter. By conducting thorough market research, having a well-defined strategy, and leveraging available support mechanisms, new companies can increase their chances of success.

Battery Industry Contribution in Indian Economy

The battery industry plays a significant role in the Indian economy across various aspects. Here’s a breakdown of its contributions:

Manufacturing and Jobs:

Established Industry: India boasts a well-established battery industry, particularly for lead-acid batteries which cater to the large automotive sector.

Employment: Battery manufacturing generates significant employment opportunities in production, logistics, and sales.

Economic Growth: The industry contributes to India’s GDP (Gross Domestic Product) through manufacturing activities and allied services.

Technological Advancement:

Focus on Lithium-ion: The growing demand for electric vehicles and portable electronics is driving the shift towards lithium-ion battery production. This fosters technological advancements in battery materials and manufacturing processes.

Government Initiatives: The Indian government recognizes the importance of lithium-ion batteries and has launched initiatives like the “Production Linked Incentive” scheme to attract investments and boost domestic manufacturing. This fosters research and development in next-generation battery technologies.

Sustainability and Environment:

Reduced Reliance on Imports: By increasing domestic battery production, India can reduce its dependence on imported batteries, potentially leading to a more stable and secure supply chain.

Electric Vehicle Adoption: A robust battery industry is crucial for the success of electric vehicles, which can contribute to reducing dependence on fossil fuels and air pollution.

Focus on Recycling: As environmental concerns rise, there’s a growing focus on cleaner battery technologies and responsible recycling practices. This can create new business opportunities and promote a more sustainable battery life cycle.

Overall Impact:

Strategic Importance: A strong battery industry is strategically important for India’s economic growth, technological advancement, and environmental goals.

Future Potential: The battery industry is expected to witness significant growth in India due to factors like:

Increasing demand for EVs and portable electronics

Government support for domestic manufacturing

Need for energy storage solutions for renewable energy integration

Challenges:

Raw Material Dependence: India relies heavily on imports for lithium and other critical battery materials, making it vulnerable to price fluctuations.

Skilled Workforce: The industry requires a skilled workforce to handle advanced battery technologies and ensure quality production.

Sustainable Practices: Developing and implementing environmentally friendly battery production and recycling methods is crucial for long-term sustainability.

By addressing these challenges and capitalizing on its strengths, the Indian battery industry has the potential to become a global leader in battery technology and contribute significantly to the country’s economic and environmental well-being.

Transportation Industry Impact Battery Industry

The transportation industry has a significant impact on the battery industry in several ways:

Demand Driver:

Electric Vehicles (EVs): The rise of EVs is the single biggest driver for the lithium-ion battery industry. As more car manufacturers shift towards electric models, the demand for high-performance, long-range batteries surges. This pushes battery companies to improve technology and increase production capacity.

Hybrid Vehicles: Hybrid electric vehicles (HEVs) also use batteries, albeit smaller ones, alongside traditional gasoline engines. This creates additional demand for different battery types.

Technology Advancement:

Battery Range and Performance: To meet the needs of the transportation industry, battery companies are constantly innovating to improve battery range, efficiency, and charging speeds. This focus on research and development benefits the entire battery industry.

Standardization and Safety: The transportation industry requires reliable and safe batteries. Collaboration between battery manufacturers, automakers, and regulatory bodies leads to standardized battery designs and safety protocols. These advancements benefit all battery applications, not just transportation.

Supply Chain and Infrastructure:

Raw Material Sourcing: The transportation industry’s large-scale battery demand drives the need for efficient and sustainable sourcing of raw materials like lithium, cobalt, and nickel. This creates opportunities for exploration, mining, and responsible material management practices throughout the battery supply chain.

Battery Recycling: As the number of electric vehicles on the road increases, there’s a growing need for efficient and environmentally friendly battery recycling processes. This focus on responsible end-of-life management benefits the entire battery industry.

Examples of Impact:

Tesla’s Gigafactories: Companies like Tesla building large-scale battery factories (Gigafactories) not only meet their own EV production needs but also put pressure on other battery manufacturers to increase efficiency and reduce costs. This benefits the entire industry.

Government Regulations: Governments around the world are setting stricter emission standards, which incentivizes automakers to adopt EVs. This in turn drives demand for batteries and pushes the battery industry for advancements.

Overall, the transportation industry acts as a major catalyst for growth and innovation in the battery industry. The need for powerful, reliable, and affordable batteries for electric vehicles is shaping the future of battery technology and its impact extends beyond just transportation, influencing the development of batteries for portable electronics, grid storage, and other applications.

Top Worldwide Battery Companies

| Rank | Company | Headquarters | Focus Area | Key Technologies |

|---|---|---|---|---|

| 1 | CATL (Contemporary Amperex Technology Co. Limited) | Ningde, China | EV Batteries | Lithium Ion (LFP & NMC) |

| 2 | LG Chem Ltd. | Seoul, South Korea | EV Batteries & Consumer Electronics | Lithium Ion |

| 3 | Panasonic Corporation | Osaka, Japan | EV Batteries & Consumer Electronics | Lithium Ion |

| 4 | BYD Co., Ltd. | Shenzhen, China | EV Batteries, Electric Vehicles & Solar Energy | Lithium Ion (LFP & Blade Battery) |

| 5 | Samsung SDI Co., Ltd. | Yongin-si, South Korea | EV Batteries & Consumer Electronics | Lithium Ion |

| 6 | SK Innovation Co., Ltd. | Seoul, South Korea | EV Batteries & Petrochemicals | Lithium Ion |

| 7 | Coslight | Taoyuan City, Taiwan | Consumer Electronics & Industrial Batteries | Lithium Ion & Lithium Polymer |

| 8 | GS Yuasa Corporation | Kyoto, Japan | Automotive & Industrial Batteries | Lead-Acid & Lithium Ion |

| 9 | Johnson Controls International plc | Cork, Ireland | Automotive Batteries & Building Technologies | Lead-Acid & Lithium Ion |

| 10 | Tesla, Inc. | Palo Alto, California, USA | Electric Vehicles & Energy Storage | Lithium Ion |

Dark Time of Battery Industries in India

While there haven’t been any periods of complete darkness for the battery industry in India, there have been phases of slower growth or challenges that could be considered less prosperous. Here are a couple of points to consider:

Pre-Liberalization Era (Before 1991):

Limited Focus on Innovation: The period before economic liberalization in India was characterized by a more closed economy. This might have limited access to advanced battery technologies and restricted domestic innovation in the battery sector.

Reliance on Lead-Acid: The focus was primarily on lead-acid batteries for the automotive industry, with less emphasis on exploring newer technologies like lithium-ion.

However, it’s important to note:

Established Lead-Acid Industry: This period also saw the rise of major Indian battery companies like Eveready and Amara Raja, which laid the foundation for a strong domestic lead-acid battery industry.

Current Challenges:

Dependence on Raw Material Imports: India relies heavily on imports for lithium and other critical battery materials, making it vulnerable to price fluctuations and supply chain disruptions.

Need for Skilled Workforce: The shift towards advanced battery technologies like lithium-ion necessitates a skilled workforce to handle production and maintenance.

Looking Forward:

Government Initiatives: The Indian government’s push for domestic battery manufacturing through schemes like the “Production Linked Incentive” scheme signifies a proactive approach to address these challenges and promote growth in the battery sector.

Overall, the Indian battery industry has come a long way and is poised for significant growth. While there have been periods with limitations, the industry has continuously evolved and adapted. By addressing current challenges and leveraging government initiatives, India has the potential to become a global leader in battery technology.

EV Evolution Impact Battery Manufacturing Industry

The rise of electric vehicles (EVs) has had a significant impact on the battery manufacturing industry, driving a wave of changes across several aspects:

Increased Demand and Production:

Surge in Lithium-Ion Batteries: EVs primarily rely on lithium-ion batteries, leading to a massive increase in demand and production compared to traditional lead-acid batteries used in gasoline vehicles. This has spurred significant growth for the lithium-ion battery manufacturing industry.

Shift in Focus: Battery manufacturers are now dedicating more resources to research, development, and production of lithium-ion batteries specifically designed for EVs, with an emphasis on factors like high energy density, longer range, and faster charging capabilities.

Technological Advancements:

Innovation Driven by Demand: The high demand for better EV batteries has fueled innovation in battery technology. Manufacturers are constantly working on improving:

Energy Density: This allows EVs to travel farther on a single charge.

Charging Speed: Faster charging times improve user convenience and address range anxiety.

Battery Life and Durability: Extending battery lifespan and improving overall performance are crucial for long-term EV adoption.

Next-Generation Technologies: The EV revolution has also accelerated research into next-generation battery technologies like solid-state batteries, which offer the potential for even higher energy density, faster charging, and improved safety.

Supply Chain Restructuring:

Raw Material Sourcing: The surge in lithium-ion battery demand has led to increased demand for critical raw materials like lithium, cobalt, and nickel. This has pushed for diversification of sourcing strategies, exploration for new resources, and potential for responsible mining practices.

Gigafactories: To meet the growing production needs, large-scale battery factories (Gigafactories) are being built by companies like Tesla and others. This trend signifies a shift towards more centralized and efficient battery production.

Economic and Environmental Impact:

Job Creation: The growth of the battery manufacturing industry creates new employment opportunities in manufacturing, research and development, and recycling sectors.

Sustainability Concerns: While EVs offer environmental benefits compared to gasoline vehicles, the battery industry faces challenges in terms of sustainable mining practices and responsible battery recycling infrastructure. Addressing these challenges is crucial for a truly sustainable EV ecosystem.

Overall, the EV revolution has been a major game-changer for the battery manufacturing industry. It has driven innovation, reshaped production processes, and created new opportunities. As the EV market continues to expand, the battery industry will likely continue to evolve and play a critical role in the transition towards a cleaner and more sustainable transportation sector.

Future of Battery Industry in India

The future of the battery industry in India looks bright, driven by several factors:

Growth Drivers:

Rising EV Demand: The Indian government’s push for electric vehicles (EVs) is a major driver. As more EVs hit the road, the demand for lithium-ion batteries will surge.

Portable Electronics Boom: The growing popularity of smartphones, laptops, and other electronic devices will continue to fuel demand for smaller lithium-ion and other battery types.

Energy Storage Solutions: The integration of renewable energy sources like solar and wind power will create a need for efficient battery storage solutions for grid stability.

Government Support:

Production Linked Incentive (PLI) Scheme: This scheme offers financial incentives to companies that set up lithium-ion battery manufacturing facilities in India. This aims to attract investment, boost domestic production, and reduce reliance on imports.

Focus on Sustainability: The government is encouraging research and development of cleaner and more sustainable battery technologies, including recycling initiatives.

Technological Advancements:

Improved Battery Performance: Battery manufacturers are constantly working on increasing range, reducing charging times, and improving the overall efficiency of batteries.

Next-Generation Technologies: Research into solid-state batteries and other next-generation technologies has the potential to revolutionize battery performance and lifespan.

Challenges to Address:

Raw Material Dependence: India currently relies heavily on imports for lithium and other critical battery materials. This can be mitigated by exploring domestic resources and establishing strategic partnerships.

Skilled Workforce: The shift towards advanced battery technologies necessitates a skilled workforce for production, maintenance, and research. Efforts are needed to bridge this skill gap through training and education programs.

Battery Recycling: Developing and implementing efficient and environmentally friendly battery recycling processes is crucial for long-term sustainability.

Overall, the Indian battery industry is poised for significant growth. By addressing these challenges and capitalizing on its strengths, India can become a global leader in battery technology and contribute to a cleaner and more sustainable future.

Here are some additional points to consider:

The rise of battery swapping stations could play a role in the future of electric mobility in India.

Innovation in battery materials and manufacturing processes will be key to cost reduction and increased accessibility.

The battery industry can create significant employment opportunities across various sectors, from manufacturing to recycling.

By staying informed about these developments, you can gain valuable insights into the future of the battery industry in India.

Battery Industry Conclusion

| Aspect | Pros | Cons |

|---|---|---|

| Economic Impact | * Creates jobs in manufacturing, research, and recycling. | * Reliant on raw material imports, leading to potential economic vulnerability. |

| Environmental Impact | * Enables electric vehicles, reducing greenhouse gas emissions and air pollution. | * Battery production can have environmental impact if not done sustainably (e.g., mining practices). * Challenge of developing efficient and environmentally friendly battery recycling infrastructure. |

| Technological Innovation | * Drives research and development in battery materials, design, and manufacturing processes. | * Ethical considerations surrounding some battery materials (e.g., cobalt mining). |

| Market Growth | * Strong demand from electric vehicles, portable electronics, and energy storage applications. | * Competition can be fierce, with rapid technological advancements. |

| Product Development | * Focus on improving battery performance (e.g., energy density, charging speed, lifespan). | * Safety concerns associated with lithium-ion batteries, requiring strict regulations and quality control. |

| Strategic Importance | * A strong battery industry is crucial for a nation’s energy security and technological independence. | * Vulnerable to geopolitical issues affecting raw material supply chains. |

The battery industry is at a pivotal point, driven by a confluence of factors:

Soaring Demand: The rise of electric vehicles and portable electronics is fueling a surge in demand for batteries, particularly lithium-ion. This creates significant growth opportunities for the battery manufacturing industry.

Technological Advancements: The industry is constantly innovating to improve battery performance in terms of energy density, charging speed, lifespan, and safety. Research into next-generation technologies like solid-state batteries holds immense potential for the future.

Strategic Importance: A strong battery industry is crucial for a nation’s economic growth, technological advancement, and environmental goals. It creates jobs, fosters innovation, and plays a key role in the transition towards cleaner energy sources.

Challenges and Opportunities:

Raw Material Dependence: Reducing reliance on imported battery materials and exploring sustainable sourcing strategies is essential.

Skilled Workforce Development: The industry needs a skilled workforce to handle advanced technologies and ensure high-quality production.

Battery Recycling: Developing and implementing efficient and environmentally friendly battery recycling processes is critical for long-term sustainability.

The Path Forward:

By addressing these challenges and capitalizing on its strengths, the battery industry can become a leader in shaping a sustainable future. Collaboration between governments, manufacturers, and researchers is key to ensure responsible sourcing, cleaner production processes, and efficient recycling practices.

For India Specifically:

The Indian battery industry has a strong foundation with established lead-acid battery production.

The government’s push for EVs and initiatives like the PLI scheme position India well to become a major player in lithium-ion battery manufacturing.

Focusing on innovation, skill development, and sustainable practices will be crucial to capture the vast potential of the battery industry in India.

Overall, the future of the battery industry is bright. As the demand for cleaner and more efficient energy solutions grows, the battery industry stands to play a transformative role in the years to come.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

ACMA The Automotive Component Manufacturers Association of India :-www.acma.in

Society of Indian Automobile Manufacturers :-www.siam.in

India Energy Storage Alliance :- www.indiaesa.info

Federation of Indian Small Scale Battery Associations :- www.fissba.org

NOTE :- From our point of view, the biggest problem today is that due to mistrust, disagreement, insecurity, today the price of our business and daily essential commodities and raw materials is increasing infinitely unnecessary.We have a small effort which is expected that every good buyer should get a good seller without a middleman and a good seller gets a good buyer.We always provide advanced information on our behalf to our customers. If you are interested in public interest by the presentation and renewal of your business, then share with us by people what revolutionary changes you have made to your business that have benefited the people.So that our good business community and you also benefit forever. And people should benefit so that a good business environment is created.

Advantage Our Pro Membership :-We provide advanced support to our pro membership clients in Transportation, Logistics, Warehousing, Finance etc….

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

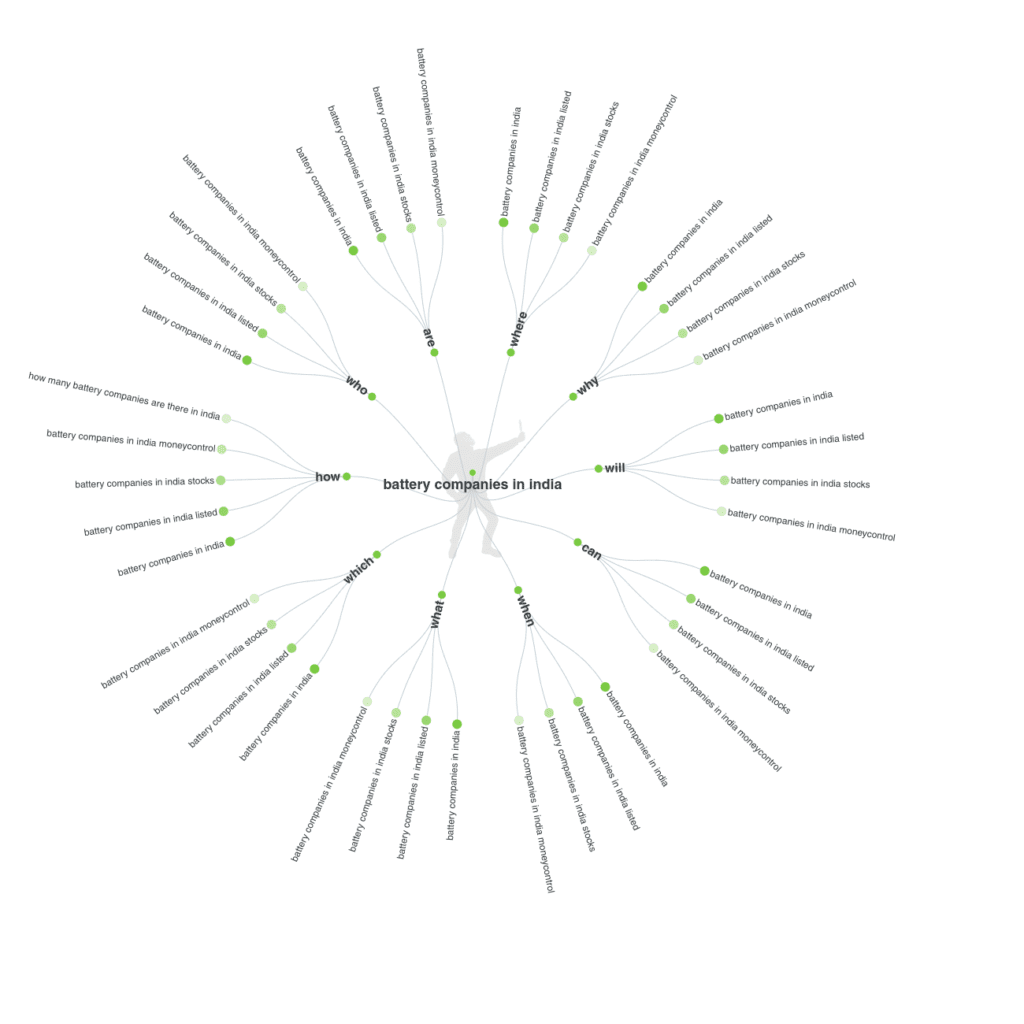

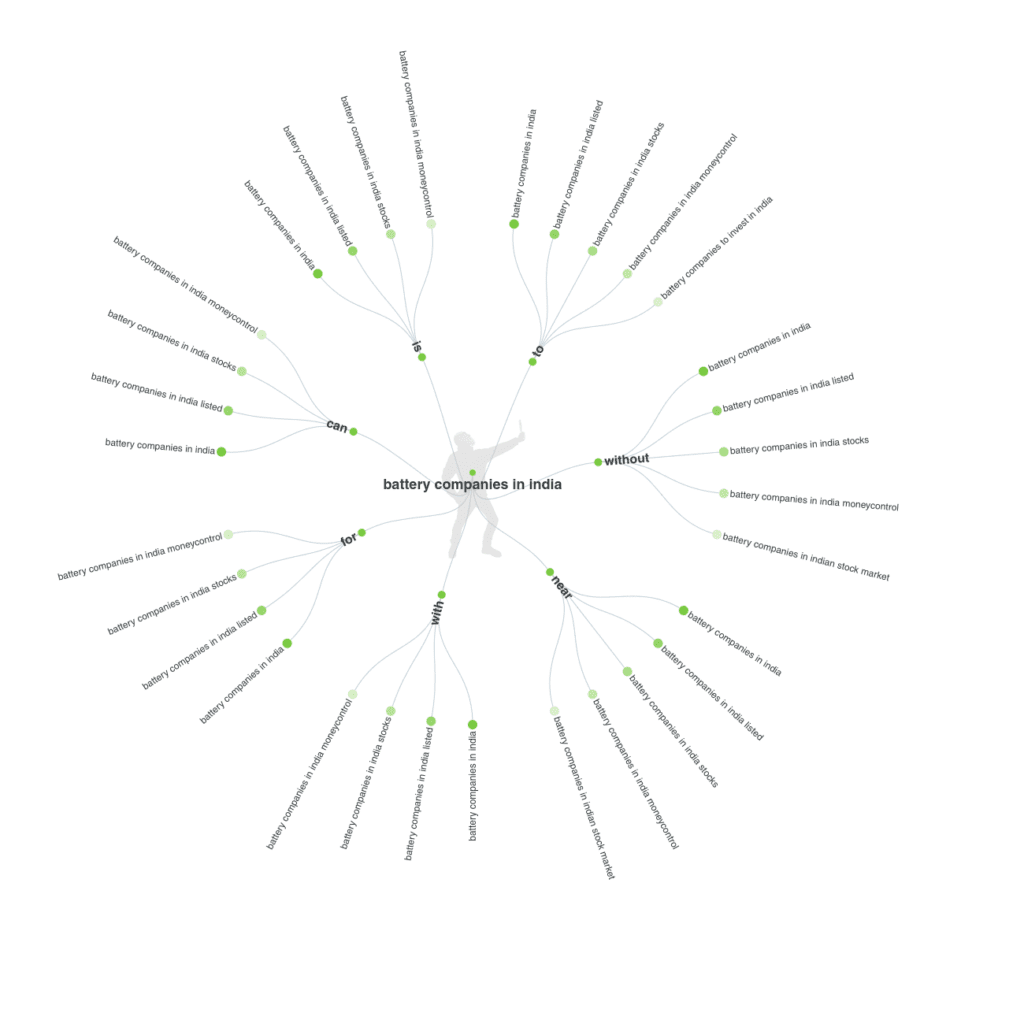

Public frequently asked questions (FAQs) :-

What is Battery answer in one sentence?

battery is a combination of two or more cells.

What is meant by battery?

battery is an electrochemical cell (or enclosed and protected material) that can be charged electrically to provide a static potential for power or released electrical charge when needed. A battery generally consists of an anode, a cathode, and an electrolyte.

What is battery and its types?

Batteries – Types & working. Batteries are the most common power source for basic handheld devices to large scale industrial applications. A battery can be defined as; it is a combination of one or more electro chemical cells that are capable of converting stored chemical energy into electrical energy.

What is a battery charge?

Battery is a type of criminal charge that involves the unauthorized application of force against another person’s body, which results in offensive touching or actual physical injury. In most instances, battery will result in misdemeanor criminal charges.

What is a battery of test?

battery of tests is a set of tests that is used to assess a number of different aspects of something, such as your health. We give a battery of tests to each patient. [ + of] Synonyms: series, set, course, chain More Synonyms of battery.

What is battery and its function?

battery is a device that stores chemical energy and converts it to electrical energy. The chemical reactions in a battery involve the flow of electrons from one material (electrode) to another, through an external circuit. The flow of electrons provides an electric current that can be used to do work.

Where do we use batteries?

Batteries are used to power things like remote controls, torch, wall clock, flashlight, hearing aids, weight scales, etc. Rechargeable batteries are also used in various devices like digital cameras, mobile phones, batteries of vehicles, video game devices, remote control cars, home maintenance tools, and many more.

What type of battery is a fuel vehicles battery?

What Are the Different Types of Auto Battery? The two most common auto batteries for sale today are standard wet cell batteries and absorbed glass mat (AGM) batteries. Both use lead-acid technology. The differences are in the needs of the car.

What should a 12 volt battery read when fully charged?

A fully charged battery will typically display a voltmeter reading of about 12.6 to 12.8 volts. If your voltmeter is showing a voltage anywhere between 12.4 and 12.8, that means your battery is in good shape. Any voltage above 12.9 volts is a good indicator that your battery has excessive voltage.

How can I test my car battery?

How to use a multimeter to test a car battery :-

Make sure the voltmeter on your multimeter is set to 20 DC volts. …

Touch the positive (red) meter probe to the positive (red) battery terminal.

Touch the negative (black) meter probe to the negative (black) battery terminal.

Ask a friend to turn the headlights on.

What causes a dead battery?

You can suffer a dead car battery for a whole host of reasons. Lack of battery maintenance (e.g., not keeping terminals clean) Failure of the diode bridge or voltage regulator in the alternator the alternator charges the battery when the car is running. Low air temperature, which causes batteries to freeze.

all batteries the same?

Not all Energizer AA alkaline batteries are made in the same place, and the quality can differ according to the manufacturing location. The place of origin can be found on the positive side of the battery.

What are main characteristics of battery?

The following battery characteristics must be taken into consideration when selecting a battery:

Type.

Voltage.

Discharge curve.

Capacity.

Energy density.

Specific energy density.

Power density.

Temperature dependence.

How important is a battery?

Batteries play numerous important roles in everyday life, from providing the initial power needed to start the engines of cars to acting as a backup source of electricity in telecommunications, public transportation and medical procedures.

How is the battery performance good?

Exide battery uses selenium metal during its manufacturing time so that their acid does not dry quickly and the battery along with the plate also gives good performance. Due to the high cost of this metal, other service providers do not use it.