What is Oil Refinery?

An oil refinery is an industrial facility that takes crude oil, a thick, black liquid, and transforms it into various useful products such as gasoline, diesel fuel, heating oil, jet fuel, asphalt, and many more .

Refineries are essential because crude oil itself isn’t directly usable in most applications. Through a complex process of distillation and chemical reactions, the many different hydrocarbons (molecules made up only of hydrogen and carbon) that make up crude oil are separated and reconfigured into more beneficial products.

Refineries are typically large, sprawling complexes with a maze of pipes, valves, tanks, and towering distillation units. These units heat the crude oil to high temperatures, separating the various hydrocarbon molecules according to their boiling points. Lighter fractions, like gasoline and propane, rise to the top of the towers, while heavier fractions, like asphalt, remain on the bottom.

After the initial separation, various processes can further convert or modify the hydrocarbons to create different products. These processes can include catalytic cracking, reforming, and alkylation. The exact mix of products produced by a refinery will depend on the type of crude oil it receives and market demands.

Related :-

Warehouse and Warehousing Storage

Types of Warehouse

Warehouse Management WMS Services

Here is a chart summarizing the history of oil refinery invention:

| Stage | Who | When | Why |

|---|---|---|---|

| Early Distillation | Samuel M. Kier | 1850s (USA) | To create a cleaner burning lamp oil from crude oil found during salt well drilling. |

| First Commercial Refinery | Samuel M. Kier & John T. Kirkpatrick | 1853 (USA) | To meet the growing demand for Kier’s lamp oil (Carbon Oil). |

| Large Scale Refinery | Ignacy Łukasiewicz (founder) | 1856-1857 (Romania) | To increase production of kerosene for lamps. |

| Modern Refining Process | Lazăr Edeleanu | 1908 (Romania) | To improve refining efficiency by developing a new method for separating hydrocarbons (Edeleanu process). |

History of Oil Refinery Industry in India

| Period | Description |

|---|---|

| Early Days (Pre-Independence) | Discovery of crude oil (1889), First refinery at Digboi (1901), Dominated by British companies |

| Post-Independence (Growth and Modernization) | First modern refinery (1954), Public sector refineries, Adoption of advanced technologies |

| Since 1980s (Diversification and Efficiency) | Early Production Systems (EPS), NELP for private participation, Cleaner fuels, Environment-friendly practices |

The Indian oil refinery industry boasts a rich history, closely tied to the discovery of oil itself. Here’s a breakdown of its evolution:

Early Days (Pre-Independence):

1889: Crude oil discovery near Digboi, Assam.

1899: Assam Oil Company established to manage production.

1901: First refinery set up at Digboi with a modest capacity of 0.5 million metric tonnes per annum (MMTPA).

Pre-1947: Dominated by British companies like Assam Oil Company, Burmah Shell, and Caltex.

Focus: Primarily met basic fuel needs, with limited processing capabilities.

Post-Independence (Growth and Modernization):

1954: First modern refinery set up at Mumbai by Esso (now HPCL).

1959: Oil India Limited (OIL) established for exploration and production.

1960s: Public sector refineries established by the government (e.g., Guwahati refinery).

Focus: Increased refining capacity, processing indigenous crude, and adopting advanced technologies (catalytic reforming).

Since 1980s (Diversification and Efficiency):

1984: Early Production Systems (EPS) introduced for quicker oil extraction.

1990s: New Exploration Licensing Policy (NELP) opened doors for private and foreign participation.

Focus: Expanding refining capacity, producing cleaner fuels with lower sulfur content, and incorporating environment-friendly practices.

Key Points to Remember:

India initially relied heavily on a single refinery at Digboi.

Post-independence, the government played a crucial role in establishing public sector refineries.

The industry has continuously modernized, adopting new technologies to meet growing fuel demands and environmental regulations.

Here’s a fact about the Indian Oil Refinery Industry:

India is the second largest refiner in Asia, after China.

This highlights the significant role India plays in refining crude oil and supplying petroleum products within Asia.

Here are some additional interesting facts you might find interesting:

Rapid Growth: Due to economic liberalization and privatization policies implemented since 1991, the Indian oil refinery industry has witnessed tremendous growth.

Large Domestic Player: Indian Oil Corporation (IOCL), the country’s largest government-owned oil producer, has a consolidated refining capacity of over 80 million metric tons per annum (MMTPA) and aims to increase it to 107 MMTPA by 2024-25.

Focus on Expansion: The private sector has significantly contributed to the industry’s growth through refinery capacity additions.

Export Hub: India is a major exporter of petroleum products, with petroleum products accounting for the highest share (16%) of Indian exports in 2022.

There are two major oil refinery companies operating in North East India:

Indian Oil Corporation Limited (IOCL):

Owns and operates the Bongaigaon Refinery located in Bongaigaon, Assam. This refinery has a capacity of 3.3 million metric tonnes per annum (MMTPA) and produces a variety of petroleum products, including gasoline, diesel, LPG, aviation fuel, and bitumen .

IOCL also owns the Guwahati Refinery located in Guwahati, Assam. This refinery has a capacity of 1.5 MMTPA and produces similar products as the Bongaigaon Refinery .

Oil India Limited (OIL):

Owns and operates the Numaligarh Refinery located in Numaligarh, Assam. This refinery has a capacity of 3 MMTPA and produces a variety of petroleum products, including gasoline, diesel, LPG, aviation turbine fuel, and industrial fuels .

Here are the major Oil Refinery Companies operating in North India:

Indian Oil Corporation Limited (IOCL): IOCL is the largest Indian corporation and a major player in the country’s refining sector. They have several refineries in North India including:

Panipat Refinery, Panipat, Haryana: This refinery has a capacity of 15 million metric tonnes per annum (MMTPA) and produces a variety of petroleum products, including gasoline, diesel, LPG, aviation turbine fuel, and petrochemicals .

Mathura Refinery, Mathura, Uttar Pradesh: This refinery has a capacity of 8.0 million metric tonnes per annum (MMTPA) and produces similar products as the Panipat Refinery .

Barauni Refinery, Barauni, Bihar: This refinery has a capacity of 6.0 million metric tonnes per annum (MMTPA) and produces gasoline, diesel, LPG, kerosene, and aviation turbine fuel .

Hindustan Petroleum Corporation Limited (HPCL): HPCL is another major state-owned oil and gas company in India. They have one refinery in North India:

Guru Gobind Singh Refinery (GGSR), Bhatinda, Punjab (joint venture with Mittal Energy Limited): This refinery has a capacity of 11.6 million metric tonnes per annum (MMTPA) and produces gasoline, diesel, LPG, aviation turbine fuel, and polypropylene .

Other Major Refineries:

Reliance Industries Limited (RIL): RIL operates the world’s largest refinery at Jamnagar, Gujarat, but it’s not located in North India.

Nayara Energy Limited: Owns and operates the Vadinar Refinery located in Vadinar, Gujarat (not North India).

Here are all the Oil Refinery Companies operating in Western India:

Reliance Industries Limited (RIL):

Owns and operates the world’s largest single-site refinery at Jamnagar, Gujarat, with a capacity of 66.8 million metric tonnes per annum (MMTPA). This refinery produces a wide range of petroleum products, including gasoline, diesel, LPG, aviation turbine fuel, petrochemicals, and polymers .

Nayara Energy Limited:

Owns and operates the Vadinar Refinery located at Vadinar, Gujarat, with a capacity of 20.1 million metric tonnes per annum (MMTPA). It produces gasoline, diesel, aviation fuel, and petrochemical products .

Bharat Petroleum Corporation Limited (BPCL):

Owns and operates the Mumbai Refinery located in Mahul, Mumbai, Maharashtra, with a capacity of 12 million metric tonnes per annum (MMTPA). This refinery produces gasoline, diesel, LPG, aviation turbine fuel, and bitumen .

Indian Oil Corporation Limited (IOCL):

Owns and operates the Gujarat Refinery at Vadodara, Gujarat, with a capacity of 13.7 million metric tonnes per annum (MMTPA). It produces gasoline, diesel, LPG, aviation turbine fuel, and petrochemicals .

Here are the Oil Refinery Companies operating in South India:

Chennai Petroleum Corporation Limited (CPCL):

Owns and operates two refineries in Tamil Nadu:

Manali Refinery located in Chennai, with a capacity of 10.5 million metric tonnes per annum (MMTPA). It produces gasoline, diesel, LPG, aviation turbine fuel, and bitumen .

Cauvery Basin Refinery located in Nagapattinam, with a capacity of 1.0 million metric tonnes per annum (MMTPA). This refinery focuses on specialty products like jet fuel and naphtha.

Bharat Petroleum Corporation Limited (BPCL):

Owns and operates the Kochi Refinery located in Kochi, Kerala, with a capacity of 15.5 million metric tonnes per annum (MMTPA). This refinery produces gasoline, diesel, LPG, aviation turbine fuel, and petrochemicals .

Mangalore Refinery and Petrochemicals Limited (MRPL): (This is a joint venture between ONGC and HPCL)

Owns and operates the Mangalore Refinery located in Mangalore, Karnataka, with a capacity of 15 million metric tonnes per annum (MMTPA). It produces gasoline, diesel, LPG, aviation turbine fuel, and petrochemicals .

It’s important to note that there might be smaller, private refineries operating in South India. However, the ones listed above are the major players in the region.

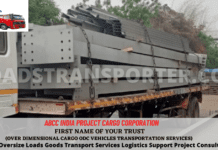

ABCC India Project Cargo Best for Oil Refinery Industries Goods Transportation

ABCC India offers project cargo transportation services that could be suitable for some goods used in oil refineries. Here’s a breakdown to help you decide:

ABCC India’s strengths:

Experience in heavy lifting and oversized cargo: They specialize in transporting large, heavy equipment, which could be relevant for certain refinery components like reactors, distillation towers, or pressure vessels.

Loading and unloading services: They can handle the loading and unloading of these heavy items, which can be a complex process.

Route survey and planning: They can survey the transportation route to ensure the feasibility and safety of the movement.

However, to determine if ABCC India is the best choice for your specific needs, consider these factors:

Type of goods: ABCC India excels with oversized and heavy cargo. If you’re transporting regular sized equipment or refined products (gasoline, diesel), other transportation companies might be more suitable.

Distance and route: ABCC India seems focused on domestic transportation within India. For international transportation, you might need a different logistics company.

Specialized requirements: Oil refineries often have specific safety regulations for transporting hazardous materials. Ensure ABCC India has the experience and certifications to handle these requirements.

Here are some next steps:

Contact ABCC India: Get a quote and discuss your specific needs. They can advise you on their capabilities for your particular oil refinery goods.

Compare with other options: Research other transportation companies specializing in oil and gas logistics. They might offer additional services or expertise relevant to your industry.

By considering these factors and getting quotes from ABCC India and other companies, you can make an informed decision about the best transportation solution for your oil refinery goods.

Basic Raw Material Suppliers for Oil Refineries (India)

| Raw Material | Supplier Type | Example Suppliers | Why They Might Be Best |

|---|---|---|---|

| Crude Oil | National & International Producers | Indian Oil Corporation (IOCL), Oil and Natural Gas Corporation (ONGC), Saudi Aramco, ExxonMobil | Established players with large production capacities and reliable supply chains. |

| Catalysts | Specialty Chemical Companies | UOP Honeywell, BASF SE, Albemarle Corporation | Offer a wide range of catalysts for various refining processes and technical expertise. |

| Chemicals | Chemical Manufacturers & Distributors | Dow Chemical Company, LyondellBasell Industries, Solvay SA | Provide various chemicals used in refinery processes like corrosion inhibitors and desalination chemicals. |

| Water Treatment Chemicals | Water Treatment Specialists | Nalco Water, Suez Water Technologies & Solutions, Ecolab | Offer specialized chemicals for water treatment in refineries, crucial for boiler operations and equipment protection. |

Oil Refinery Industry Contribution in Indian Economy

The Oil Refinery Industry plays a significant role in the Indian economy. Here’s a breakdown of its contributions:

Reduces Dependence on Imports: India is a major consumer of oil but lacks sufficient domestic crude oil reserves. Refineries process imported crude oil into usable fuels, reducing reliance on expensive finished product imports and saving foreign exchange.

Boosts Industrial Growth: Refineries act as a foundation for downstream industries like petrochemicals, fertilizers, and various manufacturing sectors. These industries utilize products from refineries as raw materials, creating a strong industrial ecosystem.

Employment Generation: The industry provides direct and indirect employment opportunities. Refineries themselves employ a large workforce, and downstream industries further contribute to job creation.

Infrastructure Development: Setting up and operating refineries involves building pipelines, storage facilities, and transportation networks. This infrastructure development benefits other sectors and improves overall logistics efficiency.

Government Revenue: Refineries contribute significantly to government revenue through taxes levied on crude oil imports, processed products, and profits. This revenue supports various government initiatives and social welfare programs.

Energy Security: A strong domestic refining capacity enhances India’s energy security. By processing imported crude oil, the country has more control over its fuel supplies and is less vulnerable to price fluctuations in the international market.

Export Potential: India has emerged as a net exporter of refined petroleum products in recent years. This not only generates additional revenue but also strengthens the country’s position in the global energy market.

Overall, the Oil Refinery Industry is a critical pillar of the Indian economy, contributing to energy security, industrial development, employment generation, and government revenue.

Oil Refinery Industry: Pros and Cons

| Pros | Cons |

|---|---|

| Energy Security: Reduces reliance on imported fuels and provides more control over fuel supplies. | Environmental Impact: Air and water pollution from refinery operations and potential oil spills. |

| Economic Benefits: Boosts industrial growth, creates jobs, generates government revenue through taxes. | Health Risks: Exposure to carcinogens and hazardous materials can cause health problems for refinery workers and surrounding communities. |

| Infrastructure Development: Creates pipelines, storage facilities, and transportation networks that benefit other sectors. | Dependence on Fossil Fuels: Contributes to climate change and limited resource availability. |

| Export Potential: Generates additional revenue and strengthens India’s position in the global energy market. | Resource Depletion: Crude oil is a finite resource, and refineries contribute to its depletion. |

| Production of Essential Products: Provides gasoline, diesel, LPG, aviation fuel, and petrochemicals needed for various sectors. | Safety Concerns: Risk of fires, explosions, and accidents during refinery operations. |

Transportation Industry Impact Oil Refinery Industry

The Transportation Industry and the Oil Refinery Industry have a mutually interdependent relationship. Here’s how they impact each other:

Transportation Industry’s Impact on Oil Refineries

Demand for Refined Products: The transportation industry is a major consumer of refined products like gasoline, diesel, aviation fuel, and marine fuels. This demand directly influences the production volumes and types of fuels produced by refineries.

Transportation Costs: The cost of transporting crude oil to refineries and refined products to consumers significantly impacts refinery profitability. Efficient transportation methods like pipelines keep these costs in check.

Shifting Transportation Trends: The rise of electric vehicles and alternative fuels like biofuels can disrupt demand for traditional petroleum products, forcing refineries to adapt and potentially diversify their output.

Oil Refinery Industry’s Impact on Transportation Industry

Fuel Availability and Prices: Refineries play a crucial role in ensuring a steady supply of transportation fuels at competitive prices. Any disruptions in refinery operations or crude oil supplies can lead to fuel shortages and price hikes, impacting transportation costs.

Fuel Quality: Refineries are constantly evolving to produce cleaner fuels with lower sulfur content, as mandated by environmental regulations. These cleaner fuels benefit the transportation industry by reducing emissions and improving engine efficiency.

Infrastructure Development: The oil refinery industry plays a role in developing transportation infrastructure like pipelines for crude oil transportation, which can be repurposed for other fuels in the future.

Looking Ahead:

The future of both industries will be shaped by the transition towards a low-carbon economy.

Refineries may need to adapt by producing cleaner fuels, biofuels, or even hydrogen for future transportation needs.

The transportation industry will look for ways to improve fuel efficiency and adopt alternative fuels to reduce dependence on traditional petroleum products.

Overall, a healthy and efficient transportation industry is essential for the smooth operation of oil refineries, and vice versa. As both industries adapt to the changing energy landscape, collaboration will be key for ensuring a sustainable future.

Top oil refinery companies worldwide, based on their refining capacity:

| Rank | Company Name | Country | Capacity (Million Barrels Per Day) |

|---|---|---|---|

| 1 | China Petroleum & Chemical Corporation (Sinopec) | China | 5.91 |

| 2 | China National Petroleum Corporation (CNPC) | China | 4.88 |

| 3 | Exxon Mobil Corporation | USA | 4.68 |

| 4 | Saudi Arabian Oil Company (Saudi Aramco) | Saudi Arabia | 4.30 |

| 5 | Indian Oil Corporation (IOCL) | India | 2.50 |

| 6 | Valero Energy Corporation | USA | 2.14 |

| 7 | Royal Dutch Shell | Netherlands | 2.11 |

| 8 | BP plc | UK | 2.00 |

| 9 | Marathon Petroleum Corporation | USA | 1.98 |

| 10 | Reliance Industries Limited (RIL) | India | 1.66 |

Dark Time of Oil Refinery Industries in India

Here are some instances that could be considered difficult periods:

Early 1970s – Oil Crisis: The global oil crisis in the 1970s impacted India significantly. Prices surged due to production cuts by OPEC countries, leading to shortages and economic disruptions. This highlighted India’s dependence on imported crude oil and the need for self-sufficiency.

Late 1990s – Asian Financial Crisis: The Asian financial crisis of 1997-98 had a ripple effect on the Indian economy, impacting demand for refined products.

2014-2016 – Oil Price Slump: A global oil price plunge between 2014 and 2016 affected refinery margins (the difference between the price of crude oil and refined products). This squeezed profits and forced some refineries to cut costs.

Recent Environmental Regulations: Stricter environmental regulations regarding emissions and cleaner fuels have necessitated upgrades and investments in refineries. While positive for the environment, these upgrades can be expensive for refineries in the short term.

Overall, the Indian oil refinery industry has shown resilience in overcoming challenges. The government’s focus on self-sufficiency, refinery modernization, and adoption of cleaner technologies are helping the industry navigate these obstacles and remain a vital contributor to the Indian economy.

Electric Vehicles Impact Indian Oil Refineries

The rise of electric vehicles (EVs) poses a significant challenge to the Indian oil refinery industry. Here’s a breakdown of the potential impact:

Decreased Demand for Transportation Fuels:

EVs run on electricity, not gasoline or diesel. As more people adopt EVs, the demand for these traditional fuels will decline. This directly impacts the profitability of refineries that produce them.

Shifting Product Focus:

Refineries may need to adapt their production processes to cater to new demands. This could involve producing:

Biofuels: Fuels derived from renewable sources like biomass, which can be blended with gasoline or diesel.

Petrochemicals: Chemicals used in various industries, such as plastics and fertilizers.

Hydrogen: A clean-burning fuel with potential applications in electric vehicles and other sectors.

Refinery Closures and Capacity Reduction:

In a worst-case scenario, some refineries might face closure if the decline in fuel demand becomes too significant.

However, there are also opportunities for the Indian oil refinery industry:

Early Stage of EV Adoption: The transition to EVs is still in its early stages in India. This provides refineries with time to adapt and explore new business models.

Focus on Cleaner Fuels: Refineries can upgrade their processes to produce cleaner versions of gasoline and diesel with lower sulfur content, complying with stricter regulations.

Integration with the EV Ecosystem: Refineries could explore opportunities to participate in charging infrastructure development or collaborate with EV manufacturers.

The Indian government is also taking steps to mitigate the impact on refineries:

Promoting Biofuels: The government is pushing for increased biofuel blending with gasoline and diesel, creating a new demand stream for refineries.

Skill Development & Transition: Programs can be implemented to help refinery workers develop skills relevant to the evolving energy sector.

Overall, the impact of EVs on Indian oil refineries will depend on the pace of EV adoption and the industry’s ability to adapt. Embracing innovation and exploring new opportunities will be crucial for the long-term success of the oil refinery industry in India.

Related :-

Trucks Truckers and Trucking

Goods Transportation Problems

Logistics Overview

Factories survey

Indian Oil Refinery Industry Conclusion

The Indian oil refinery industry has come a long way, from its humble beginnings with a single refinery at Digboi to becoming a global leader with a massive refining capacity. Here’s a summary of its key points and future considerations:

Key Points:

Growth and Modernization: The industry has undergone significant growth and modernization, with a focus on increasing capacity, adopting advanced technologies, and producing cleaner fuels.

Strategic Importance: Refineries play a crucial role in reducing import dependence, boosting industrial growth, generating revenue, and ensuring energy security.

Challenges and Opportunities: The rise of electric vehicles and stricter environmental regulations pose challenges, but also present opportunities for diversification into biofuels, petrochemicals, and cleaner fuels.

Future Considerations:

Adapting to Change: The industry needs to adapt to the evolving energy landscape by embracing innovation and exploring new business models.

Sustainability: Focus on cleaner technologies, energy efficiency, and responsible waste management will be crucial for long-term sustainability.

Collaboration: Collaboration between government, refineries, and other stakeholders is essential to navigate the transition towards a low-carbon future.

Overall, the Indian oil refinery industry is at a crossroads. While the rise of EVs presents a challenge, its future success hinges on its ability to adapt, embrace new technologies, and contribute to a sustainable energy future for India.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

India Refining Summit :- www.refining-technology.com

NOTE :- From our point of view, the biggest problem today is that due to mistrust, disagreement, insecurity, today the price of our business and daily essential commodities and raw materials is increasing infinitely unnecessary.We have a small effort which is expected that every good buyer should get a good seller without a middleman and a good seller gets a good buyer.We always provide advanced information on our behalf to our customers. If you are interested in public interest by the presentation and renewal of your business, then share with us by people what revolutionary changes you have made to your business that have benefited the people.So that our good business community and you also benefit forever. And people should benefit so that a good business environment is created.

Advantage Our Pro Membership :-We provide advanced support to our pro membership clients in Transportation, Logistics, Warehousing, Finance etc….

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

Public frequently asked questions (FAQs) :-

What is the largest oil refinery in the world?

The largest oil refinery in the world, based on crude processing capacity, is the Jamnagar Refinery Complex located in Jamnagar, India. It’s owned by Reliance Industries Limited (RIL).

This refinery complex actually consists of two refineries operating side-by-side with a combined capacity of 1.24 million barrels per day (bpd) . It plays a significant role in India’s oil refining sector and contributes to the country’s position as a net exporter of refined petroleum products .

How does oil refining process work?

Oil refining is the process of transforming crude oil, a thick, black liquid, into various usable products like gasoline, diesel, and petrochemicals. Here’s a simplified breakdown of the key steps involved:

Separation (Distillation):

Crude oil is a mixture of numerous hydrocarbons (molecules containing hydrogen and carbon) with varying boiling points.

The crude oil is heated in a furnace, and then enters a distillation tower.

Inside the tower, different temperature zones exist. Hydrocarbons with lower boiling points rise higher in the tower and vaporize first.

These vapors are then collected and condensed into separate streams based on their boiling points, resulting in products like gasoline, naphtha (used for making plastics), and kerosene.

Conversion (Cracking):

Heavier hydrocarbon molecules remaining after distillation have high boiling points and aren’t directly usable.

A cracking process breaks down these heavier molecules into lighter, more valuable products like gasoline and diesel fuel.

There are different types of cracking, such as thermal cracking (using heat) and catalytic cracking (using a catalyst to improve efficiency).

Treatment:

The products from distillation and conversion may still contain impurities like sulfur or nitrogen compounds.

Treatment processes like hydrotreating use hydrogen to remove these impurities, resulting in cleaner fuels that meet environmental regulations.

Blending:

The final stage involves blending the various refined products to achieve the desired properties for the end product.

For example, gasoline may be blended with additives to improve octane rating or performance.

Storage and Transportation:

The finished products are then stored in tanks and transported via pipelines, trucks, or ships to distribution centers and ultimately to consumers.

Which city has an oil refinery?

Many cities around the world have oil refineries! Here are a few examples:

Jamnagar, India: Home to the world’s largest oil refinery complex, the Jamnagar Refinery owned by Reliance Industries Limited.

Houston, Texas, USA: A major center for the oil and gas industry in the United States, with several refineries located there.

Rotterdam, Netherlands: The largest port in Europe, also houses a major oil refining hub.

Singapore: A global center for oil refining and trading, with several refineries strategically located on the island nation.

Mumbai, India: Home to multiple refineries including those owned by Hindustan Petroleum Corporation Limited (HPCL) and Bharat Petroleum Corporation Limited (BPCL).

This is not an exhaustive list, and there are many other cities with oil refineries around the world.

Which country refines the most oil?

There are two strong contenders for the title of country refining the most oil:

United States: The United States has the highest total oil refining capacity, according to data from 2021. With a capacity of around 17.94 million barrels per day (mbpd), the US accounts for roughly 20% of the world’s total refining capacity .

China: China is rapidly growing its refining industry and may have already surpassed the US. Estimates suggest China’s refining capacity reached 19 million barrels per day in 2023 .

Where is the world’s largest oil field?

The Ghawar oilfield is the largest oil field in the world.

Which is the biggest oil refinery in Assam Northeastern India ?

Digboi Refinery

Which is the richest oil field in India?

The largest oil field of India is Bombay high. It is situated about 161 km north of Bombay coast in Mumbai, Maharashtra.

Assam rich in petroleum?

While investing in the ever-fluctuating oil sector also has its share of risks, it appears that the government is willing to take that risk and if it pays off, Assam could well be on the path of an oil-rich economy. But it is a long road; the refinery capacity in Assam compared to other states is abysmally low.

Who started the oil industry?

The modern US petroleum industry is considered to have begun with Edwin Drake’s drilling of a 69-foot (21 m) oil well in 1859, on Oil Creek near Titusville, Pennsylvania, for the Seneca Oil Company (originally yielding 25 barrels per day (4.0 m3/d), by the end of the year output was at the rate of 15 barrels per day

Which state is the largest producer of oil in India?

The three largest producers of mineral oil or crude oil in India are Rajasthan (23.7%), Gujarat (12.5%), Assam (12.1%). Among these three states Assam is the largest producer of mineral oil in India.

Why does India has to import oil?

India relies heavily on oil imports due to a combination of factors:

Limited Domestic Crude Oil Reserves: India has proven crude oil reserves that are relatively modest compared to its consumption needs. While there have been some discoveries in recent years, domestic production can’t meet the country’s growing demand for oil.

High Demand for Oil: India’s population is massive and continues to grow. This translates to a constantly increasing demand for transportation fuels, petrochemicals, and other products derived from oil.

Focus on Refining: India has a well-developed oil refining industry, but its crude oil refining capacity often surpasses domestic production. This makes the country reliant on imports to keep its refineries operational and meet product demands.

Economic Growth: India’s rapid economic growth has further fueled the demand for energy, including oil-based products. This growth outpaces the ability of domestic oil production to keep up.

Types of Oil Imports:

Light Crude Oil: India imports a significant amount of light crude oil, which is easier to refine into transportation fuels like gasoline and diesel.

Heavy Crude Oil: Some refineries in India are also equipped to handle heavier crude oil, which can be cheaper but requires more complex refining processes.

Efforts to Reduce Dependence:

Exploration and Production: The Indian government is investing in exploring for new oil reserves within the country and developing existing fields to increase domestic production.

Renewable Energy: India is pushing for a shift towards renewable energy sources like solar and wind power to reduce reliance on imported oil for electricity generation.

Biofuels: Promoting biofuel production and blending with gasoline and diesel is another strategy to reduce dependence on imported oil.

Overall, reducing oil import dependence is a long-term goal for India. Efforts are underway to explore new domestic reserves, diversify energy sources, and improve energy efficiency.

What do oil refineries do?

Oil refineries take crude oil, a thick, black liquid, and transform it into various usable products we rely on in our daily lives. Here’s a breakdown of what oil refineries do:

Main Function: Refine crude oil into a variety of petroleum products.

Key Products:

Transportation fuels: Gasoline, diesel, aviation fuel, and marine fuels used to power vehicles, airplanes, and ships.

Petrochemicals: The building blocks for various products like plastics, fertilizers, clothing, and many more.

Liquefied petroleum gas (LPG): Used for cooking, heating, and industrial applications.

Asphalt: Used for paving roads and roofing materials.

The Refining Process (Simplified):

Separation (Distillation): Crude oil is a mixture of hydrocarbons (molecules with hydrogen and carbon) with varying boiling points. Heating the oil separates these components based on their boiling points, resulting in products like gasoline and kerosene.

Conversion (Cracking): Heavier oil components left over from distillation are broken down into lighter, more valuable products like gasoline and diesel fuel through processes like thermal cracking or catalytic cracking.

Treatment: The products may still contain impurities. Treatment processes remove these impurities to create cleaner fuels that meet environmental regulations.

Blending: The various refined products are blended to achieve the desired properties for the final product. For example, gasoline may be blended with additives to improve performance.

Storage and Transportation: The finished products are stored in tanks and then transported via pipelines, trucks, or ships to distribution centers and ultimately to consumers.

Overall, oil refineries play a vital role in our modern world by providing the essential fuels and petrochemical feedstocks that power our transportation systems and contribute to countless products we use every day.

What are the largest oil companies in the world?

There are two main ways to define “largest” oil companies: by revenue or by crude oil refining capacity. Here’s a breakdown for both categories:

Largest Oil Companies by Revenue (as of 2023):

Saudi Aramco (Saudi Arabia): This state-owned company is the world’s largest oil producer and a major integrated oil and gas company. While its stock is not publicly traded on major exchanges, estimates suggest it has the highest revenue among oil companies.

China Petroleum & Chemical Corporation (Sinopec) (China): A state-owned conglomerate involved in oil and gas exploration, refining, marketing, and petrochemicals.

China National Petroleum Corporation (CNPC) (China): Another state-owned Chinese oil and gas giant, with a global presence across various sectors of the industry.

Exxon Mobil Corporation (USA): An American multinational oil and gas company with a large refining capacity and presence across the oil and gas value chain.

Shell plc (Netherlands): A multinational oil and gas company headquartered in the Netherlands, with a global network of refineries and marketing operations.

Largest Oil Companies by Crude Oil Refining Capacity (as of 2023):

Reliance Industries Limited (RIL) (India): The Jamnagar Refinery Complex in India, owned by RIL, is the world’s largest refinery by capacity.

Sinopec Group (China): While not a single refinery, Sinopec as a group has a massive total refining capacity across its various facilities in China.

Exxon Mobil Corporation (USA): Exxon Mobil has a large refining capacity spread across various refineries globally.

Saudi Aramco (Saudi Arabia): Despite being the world’s largest oil producer, Saudi Aramco’s refining capacity isn’t the biggest globally, but it’s still significant.

National Iranian Oil Company (NIOC) (Iran): A state-owned Iranian oil company with a large refining capacity focused on domestic consumption and regional exports.

Important Note:

Data on refining capacity can vary depending on the source, so the exact ranking might differ slightly depending on the source you consult.