What is Auto Components ?

Auto components are the various parts that make up a motor vehicle. There are thousands of different auto components, from the engine and transmission to the wheels and brakes. These components work together to allow a car to function properly.

Auto components are the various parts that make up a motor vehicle. There are thousands of different auto components, from the engine and transmission to the wheels and brakes. These components work together to allow a car to function properly.

Here are some of the major categories of auto components:

Engine components: These include the engine block, cylinder head, pistons, valves, crankshaft, and camshaft. The engine is responsible for converting fuel into power to propel the car.

Drivetrain components: These include the transmission, driveshaft, differential, and axles. The drivetrain transfers power from the engine to the wheels.

Suspension and steering components: These include the shock absorbers, struts, springs, control arms, tie rods, and steering wheel. The suspension system absorbs bumps and road irregularities, while the steering system allows the driver to control the direction of the car.

Brake components: These include the brake pads, rotors, calipers, and master cylinder. The brakes are used to slow down and stop the car.

Electrical components: These include the battery, alternator, starter motor, spark plugs (in gasoline engines), and wiring harness. The electrical system provides power to the car’s various components.

Body components: These include the frame, fenders, doors, hood, and trunk. The body provides structure and support for the car’s other components.

Interior components: These include the seats, dashboard, steering wheel, instrument panel, and air conditioning system. The interior provides a comfortable and functional environment for the driver and passengers.

Auto components are constantly being improved to make cars more efficient, safer, and more comfortable. New technologies, such as electric vehicles and autonomous vehicles, are also having a major impact on the auto components industry.

Related :-

Warehouse and Warehousing Storage

Types of Warehouse

Warehouse Management WMS Services

Who When and Why Invented Auto Components (Spare Parts) ?

Attributing invention to a single person for most auto components is difficult because car development wasn’t a one-man show. It involved numerous inventors and engineers constantly improving upon existing ideas. Here’s a breakdown of the invention of auto components:

The groundwork: The concept of self-propelled vehicles goes back centuries, with early steam-powered carriages emerging in the 17th century. Inventors like Nicolas-Joseph Cugnot (1769) and François Isaac de Rivaz (early 1800s) with their steam and internal combustion engines laid the foundation for future automobiles.

The rise of gasoline cars: The late 19th century saw the birth of the modern car. Gottlieb Daimler and Karl Benz (1880s) are credited with creating practical gasoline-powered automobiles, requiring numerous new components like internal combustion engines, radiators, transmissions, and steering systems.

Continuous innovation: Since then, countless inventors and engineers have refined these components. For instance, the MacPherson strut suspension system, commonly used today, was invented by Earle S. MacPherson in the mid-20th century while working for General Motors.

Standardization and mass production: The rise of mass production necessitated interchangeable parts. Eli Whitney in the early 1800s is considered a pioneer of interchangeable parts, although the concept wasn’t widely applied to cars until the early 20th century. This standardization allowed for easier repairs and replacements, leading to the concept of “spare parts.”

So, while there isn’t a single inventor for most auto components, the late 19th century with the rise of gasoline cars saw a surge in innovation for core components. Since then, countless engineers and inventors have continued to improve upon these parts.

The Evolution of India’s Auto Components Industry (Spare Parts)

The story of India’s auto components industry goes hand-in-hand with the development of its automobile industry. Here’s a breakdown of the key phases:

Early Days (Pre-Independence):

Limited car usage: Cars were mainly imported luxuries before independence in 1947.

Dependence on imports: Spare parts were also mostly imported, creating a gap for a domestic spare parts industry.

Post-Independence (1947 onwards):

Import substitution and Self-reliance (1950s-1980s):

The government prioritized building a domestic auto industry to reduce reliance on imports.

Import substitution policies encouraged the production of auto components in India.

Companies like Hindustan Motors and Premier set up shop, creating a demand for spare parts.

Small and medium enterprises (SMEs) emerged as key players, catering to the growing market.

Globalization and Collaboration (1980s onwards):

Liberalization policies opened doors for foreign automakers like Maruti Suzuki and Hyundai.

Increased demand for diverse and sophisticated spare parts.

Collaboration between Indian and foreign companies led to technology transfer and improved component quality.

Rise of exports: Indian spare parts started finding markets abroad.

Recent Developments (2000s onwards):

Focus on innovation: Meeting the demands of new vehicle technologies like electric vehicles.

Growth of organized sector: Large players are consolidating the market, while SMEs continue to play a vital role.

Increasing focus on quality and international standards.

Key factors driving the Indian auto component industry:

Growing domestic auto market: Rising car ownership fuels the demand for spare parts.

Strong presence of global automakers: Creates a market for high-quality components.

Cost-competitiveness: Indian manufacturers offer competitive production costs.

Skilled workforce: A large pool of skilled engineers and technicians supports the industry.

Challenges and future outlook:

Technological disruption: Adapting to new technologies like electric vehicles requires innovation.

Competition from established players: Indian companies face competition from global giants.

Maintaining quality standards: Meeting stricter emission and safety regulations.

Despite the challenges, India’s auto component industry is expected to keep growing, driven by the domestic auto market boom and increasing exports. The industry is well-positioned to become a global leader in the future.

Fact About Indian Auto Components (Spare Parts) Industry

The Indian auto components industry is a significant contributor to the country’s economy and plays a crucial role in the growth of the automotive sector. Here are some facts about the Indian auto components (spare parts) industry:

- Size and Growth: The Indian auto components industry is one of the largest in the world, with a turnover of over $57 billion as of recent data. It has been witnessing steady growth over the years, driven by both domestic demand and exports.

- Contribution to GDP: The industry contributes significantly to India’s GDP and employs millions of people directly and indirectly across the country. It is estimated to contribute around 2.3% to India’s GDP.

- Diverse Product Range: The Indian auto components industry manufactures a wide range of products including engine parts, transmission parts, steering and suspension components, electrical parts, rubber components, plastic components, and more. This diversity enables it to cater to both domestic and international markets.

- Export Potential: India is emerging as a global hub for auto component manufacturing and exports. The industry exports its products to various countries around the world, including the United States, Europe, Latin America, and Asia. This export orientation has helped in increasing foreign exchange earnings for the country.

- Technology and Innovation: Indian auto component manufacturers are increasingly investing in research and development (R&D) to enhance product quality and develop innovative solutions. This focus on technology and innovation has enabled them to stay competitive in the global market.

- Government Support: The Indian government has been supportive of the auto components industry through various initiatives such as the Automotive Mission Plan (AMP) and policies promoting foreign investment, technology upgradation, and skill development. These initiatives aim to boost domestic production, exports, and overall competitiveness of the industry.

- Integration with Automotive OEMs: Auto component manufacturers in India have strong ties with automotive original equipment manufacturers (OEMs). Many global OEMs have set up manufacturing facilities in India, leading to increased demand for locally sourced components.

Overall, the Indian auto components industry is poised for further growth, driven by factors such as rising vehicle production, increasing investments in infrastructure, and the adoption of advanced technologies.

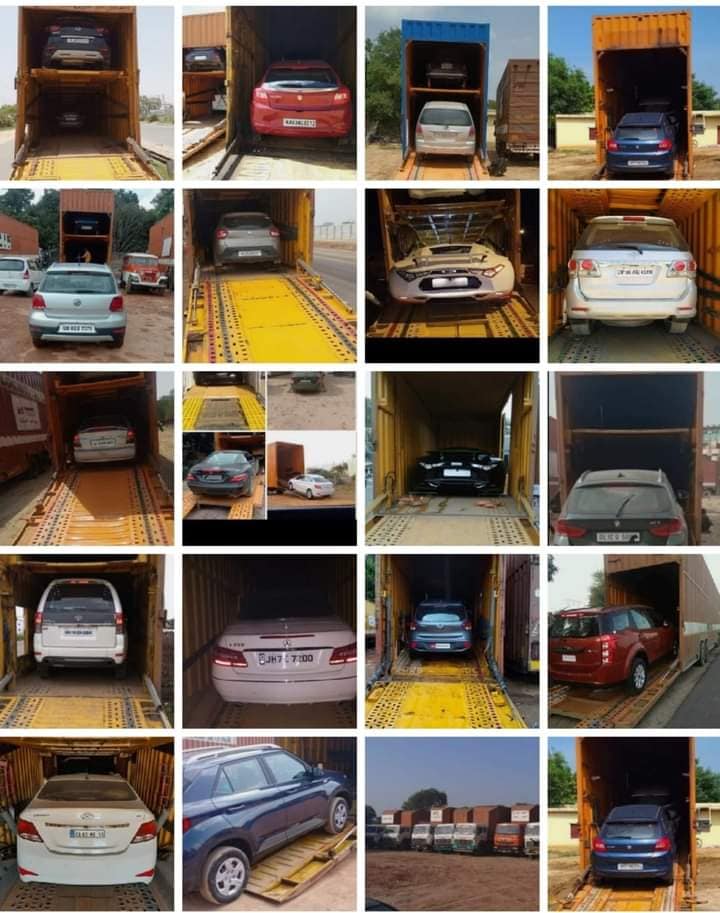

ABCC India Project Cargo Best for Auto Components (Spare Parts) Industries Goods Transportation

For the seamless transportation of auto components and spare parts, ABCC India Project Cargo stands out as your reliable partner. With a proven track record in the logistics industry, ABCC India Project Cargo offers tailored solutions designed to meet the unique needs of the auto components sector.

Experience Matters: Benefit from our extensive experience in handling auto components, gained through years of serving clients in the industry. We understand the intricate requirements and challenges associated with transporting valuable and delicate spare parts.

Reliability and Timeliness: Count on ABCC India Project Cargo for punctual and reliable delivery of your goods. Our commitment to timeliness ensures that your auto components reach their destination on schedule, minimizing production disruptions and keeping your operations running smoothly.

Safety and Security: Rest assured that your cargo is in safe hands with ABCC India Project Cargo. We prioritize the safety and security of your auto components throughout the transportation process, employing stringent measures to protect them from damage or loss.

Efficient Customs Clearance: Navigate international borders seamlessly with our expertise in customs clearance and documentation. We streamline the customs process to ensure swift transit of your goods, minimizing delays and optimizing supply chain efficiency.

Cost-Effective Solutions: Achieve cost savings without compromising on quality with ABCC India Project Cargo. Our competitive pricing combined with exceptional service makes us the ideal choice for cost-conscious auto component manufacturers.

Advanced Technology and Tracking: Gain real-time visibility into your shipments with our advanced tracking technology. Monitor the status of your auto components throughout their journey, providing you with peace of mind and control over your logistics operations.

Dedicated Customer Service: Experience personalized and attentive customer service every step of the way with ABCC India Project Cargo. Our team is committed to addressing your needs and concerns promptly, ensuring a seamless transportation experience.

Choose ABCC India Project Cargo for your auto components transportation needs and experience excellence in logistics. Let us be your trusted partner in driving the success of your business.

Basic Raw Material Supplier in Auto Components (Spare Parts) Industries

| Raw Material | Supplier Examples | Why They Might Be Considered Good Options |

|---|---|---|

| Steel | * Tata Steel Limited (Mumbai) * ArcelorMittal Nippon Steel India Limited (Mumbai) | Reputed brands with extensive product lines for automotive applications, offering high strength and quality steel. |

| Aluminium | * Hindalco Industries Limited (Mumbai) * Vedanta Limited (Mumbai) | Major producers of aluminium catering to the auto industry, known for lightweight and corrosion-resistant aluminium products. |

| Rubber | * MRF Ltd (Chennai) * Apollo Tyres Ltd (Gurgaon) | Leading tyre manufacturers in India, also supplying rubber compounds for various auto parts. |

| Plastics | * Reliance Industries Limited (Mumbai) * BASF India Limited (Mumbai) | Major chemical companies offering a wide range of plastic materials for diverse auto component applications. |

| Glass | * Asahi India Glass Ltd (Pune) * Saint-Gobain India Pvt Ltd (Gurgaon) | Reputable manufacturers of automotive glass known for quality and safety features. |

Top 10 Auto Components Spare Parts Manufacturing Domestic Companies in India

Here are the top 10 auto components spare parts manufacturing domestic companies in India:

- Bharat Forge Limited: A global leader in metal forming and forging technology, Bharat Forge manufactures a wide range of auto components including engine parts, chassis components, transmission parts, and more.

- Motherson Sumi Systems Limited: Motherson Sumi Systems is a leading supplier of automotive wiring harnesses, rearview mirrors, polymer components, and other automotive parts to major OEMs worldwide.

- Bosch Limited: Bosch is a renowned multinational engineering and technology company that manufactures automotive components such as fuel injection systems, braking systems, electrical components, and more.

- Exide Industries Limited: Exide is India’s leading manufacturer of automotive and industrial batteries, providing a wide range of batteries for various vehicle applications.

- Mahindra CIE Automotive Limited: Mahindra CIE Automotive is a joint venture between Mahindra Group and CIE Automotive, Spain. It manufactures a diverse range of automotive components including forgings, castings, and magnetic products.

- TVS Group: TVS Group consists of several companies including TVS Motor Company, Sundaram-Clayton Limited, and others, which manufacture auto components such as brakes, wheels, exhaust systems, and more.

- Sundram Fasteners Limited: Sundram Fasteners is one of the largest manufacturers of high-tensile fasteners, powder metal components, and precision components for automotive applications.

- Rane Group: Rane Group is a leading manufacturer of auto components such as steering and suspension systems, engine valves, and other precision-engineered products for the automotive industry.

- Gabriel India Limited: Gabriel India specializes in the manufacturing of ride control products such as shock absorbers, struts, and front forks for motorcycles, passenger cars, and commercial vehicles.

- Amara Raja Batteries Limited: Amara Raja Batteries is a prominent manufacturer of automotive and industrial batteries under the brands Amaron and PowerZone, catering to the needs of various vehicle segments.

These companies have established themselves as key players in the Indian auto components industry, providing high-quality products and innovative solutions to meet the demands of both domestic and international markets.

Top 10 Auto Components Spare Parts Manufacturing Global Companies in India

While several global auto components spare parts manufacturing companies have a significant presence in India, it’s important to note that not all of them have manufacturing facilities within the country. However, many of these companies have established distribution networks, joint ventures, or partnerships with Indian companies to serve the Indian market. Here are ten global auto components spare parts manufacturing companies that have a notable presence in India:

- Bosch Limited: Bosch is a global leader in automotive technology and components, with a significant presence in India. The company manufactures a wide range of automotive parts, including fuel injection systems, braking systems, electrical components, and more.

- ZF Friedrichshafen AG: ZF is a leading global supplier of driveline and chassis technology, as well as active and passive safety technology. The company has a presence in India and provides advanced automotive components to major OEMs.

- Continental AG: Continental is a German automotive manufacturing company known for its tires, brake systems, automotive safety, and powertrain components. Continental has a significant presence in India, supplying various automotive components to the Indian market.

- Magna International Inc.: Magna is a Canadian automotive supplier that designs, develops, and manufactures automotive systems, assemblies, modules, and components. The company has operations in India, providing a wide range of automotive solutions to OEMs.

- Denso Corporation: Denso is a Japanese automotive supplier that provides advanced technology, systems, and components for automakers worldwide. Denso has a presence in India and supplies various automotive components to the Indian market.

- Aisin Seiki Co., Ltd.: Aisin Seiki is a Japanese automotive components manufacturer that produces a wide range of products such as brakes, transmissions, drivetrain, chassis, and engine parts. The company has operations in India to cater to the local automotive industry.

- Valeo SA: Valeo is a French global automotive supplier that designs, manufactures, and distributes automotive parts worldwide. Valeo has a presence in India and supplies various automotive components, including lighting systems, wipers, and thermal systems.

- Mahle GmbH: Mahle is a German automotive parts manufacturer that specializes in engine components, filtration, and thermal management systems. The company has operations in India and supplies automotive components to OEMs in the country.

- Delphi Technologies (now part of BorgWarner Inc.): Delphi Technologies, now part of BorgWarner, is a global automotive supplier known for its powertrain and electrification solutions. The company has a presence in India and provides advanced automotive components to OEMs.

- Mitsubishi Electric Corporation: Mitsubishi Electric is a Japanese multinational electronics and electrical equipment manufacturing company. It supplies various automotive components, including electrical systems, to the Indian market.

These companies, among others, contribute to the growth and development of the Indian auto components industry by providing advanced technology, innovative solutions, and high-quality products to meet the demands of the domestic automotive market.

Auto Components (Spare Parts) Industry Contribution in Indian Economy

The auto components (spare parts) industry plays a significant role in the Indian economy, contributing to various aspects of economic growth, employment generation, exports, and technological advancement. Here are some key contributions of the auto components industry to the Indian economy:

- Contribution to GDP: The auto components industry is a vital contributor to India’s Gross Domestic Product (GDP). It accounts for a significant portion of the manufacturing sector’s output and contributes directly to the country’s economic growth.

- Employment Generation: The industry is a major source of employment, providing jobs to millions of people across the country. It encompasses a wide range of activities, including manufacturing, research and development, sales, distribution, and aftermarket services, thereby creating diverse employment opportunities.

- Revenue Generation and Investment: The auto components industry generates substantial revenue through domestic sales and exports. It attracts significant investments in manufacturing facilities, technology upgrades, research and development, and infrastructure development, driving economic growth and industrial development.

- Export Growth: India has emerged as a global hub for auto components manufacturing and exports. The industry exports a wide range of components to various countries around the world, contributing significantly to foreign exchange earnings and enhancing India’s position in the global market.

- Integration with Automotive Sector: The auto components industry is closely integrated with the automotive sector, which is one of the largest contributors to India’s manufacturing output. Strong backward and forward linkages between auto manufacturers and component suppliers contribute to the overall growth and competitiveness of the automotive ecosystem.

- Technology Upgradation and Innovation: The industry plays a crucial role in driving technological innovation and upgradation in the automotive sector. Auto component manufacturers invest in research and development to develop advanced products, improve manufacturing processes, and meet the evolving needs of domestic and global markets.

- Support for MSMEs: The auto components industry provides significant support to Micro, Small, and Medium Enterprises (MSMEs) through subcontracting, ancillary development, and technology transfer. This promotes entrepreneurship, industrial diversification, and inclusive growth in the economy.

- Infrastructure Development: The growth of the auto components industry spurs investments in infrastructure development, including manufacturing facilities, logistics networks, and transportation systems. This contributes to the overall development of industrial infrastructure in the country.

In summary, the auto components industry is a crucial pillar of the Indian economy, driving growth, innovation, and employment while contributing to India’s global competitiveness in the automotive sector. Its sustained growth and development are essential for the overall economic progress of the country.

Transportation Industry Impact Auto Components (Spare Parts) Industry

The Transportation Industry and the Auto Components (Spare Parts) Industry have a symbiotic relationship. They heavily influence and rely on each other for growth and success. Here’s a breakdown of this two-way impact:

Transportation Industry Impact on Auto Components Industry:

Demand Driver: The growth of the transportation industry directly impacts the demand for auto components. More vehicles on the road lead to a higher need for spare parts for maintenance, repair, and replacement.

Technological Advancements: The transportation industry’s shift towards electric vehicles, autonomous vehicles, and cleaner technologies necessitates the auto component industry to innovate and develop new parts catering to these advancements.

Safety Regulations: Stricter safety regulations imposed on vehicles require the auto component industry to produce parts that meet these standards, promoting safety features and component quality.

Auto Components Industry Impact on Transportation Industry:

Efficiency and Performance: High-quality and reliable auto components ensure efficient vehicle operation, minimizing breakdowns and keeping transportation running smoothly.

Cost-Effectiveness: Affordable spare parts make vehicle maintenance more accessible, contributing to the overall cost-effectiveness of transportation for businesses and individuals.

Safety and Reliability: Safe and reliable auto components are crucial for preventing accidents and ensuring safe transportation of people and goods.

Examples of this Impact:

The rise of ride-sharing services like Uber and Ola has increased demand for spare parts due to the high utilization rates of these vehicles.

The push for cleaner transportation has led to the development of electric vehicle components like batteries and electric motors.

Advancements in braking systems and airbags have improved road safety, driven partly by innovations in the auto component industry.

Future Outlook:

As the transportation industry evolves with autonomous vehicles, alternative fuels, and increasing connectivity, the auto component industry will need to adapt and innovate to meet these changing demands. Collaboration between the two industries will be crucial for developing sustainable and efficient transportation solutions for the future.

EV Industry Impact of Auto Components (Spare Parts) Industries in India

The rise of the Electric Vehicle (EV) industry presents both opportunities and challenges for the Indian Auto Components (Spare Parts) industry. Here’s a breakdown of the impact:

Opportunities:

New Component Production: EVs require entirely different components compared to traditional vehicles. This opens doors for Indian manufacturers to produce electric motors, battery management systems, power electronics, and charging equipment.

Market Growth: The projected growth of the Indian EV market creates a significant demand for these new components, offering an opportunity for the auto component industry to expand its market share.

Technological Leap: The shift to EVs necessitates innovation and technological advancements. This can propel the Indian auto component industry towards becoming a global leader in EV component manufacturing.

Export Potential: India can potentially become a major exporter of EV components catering to the global EV market.

Challenges:

Shifting Skillsets: Manufacturing EV components requires a different skillset compared to traditional components. The industry needs to invest in training and upskilling its workforce to adapt to the changing demands.

Competition: Established global players already dominate the EV component market. Indian companies need to focus on innovation, cost-effectiveness, and quality to compete effectively.

Disrupted Aftermarket: EVs generally require less maintenance than traditional vehicles, potentially leading to a decline in the demand for replacement parts like engine components and lubricants. The industry needs to diversify its offerings to cater to the evolving needs of the EV market.

Examples:

Several Indian companies are already making strides in EV components. Companies like Bharat Forge and Tata Autocomp are developing electric motors and other EV-specific parts.

Government initiatives like the PLI (Production Linked Incentive) scheme aim to attract investments and boost domestic manufacturing of EV components.

Overall Impact:

The EV industry will undoubtedly transform the Indian Auto Components industry. While challenges exist, the potential opportunities are significant. By embracing innovation, reskilling the workforce, and focusing on areas like battery technology and charging infrastructure, the Indian auto component industry can adapt and thrive in the EV era.

Dark Time of Auto Components (Spare Parts) Industries in India

The auto components (spare parts) industry in India, like any other sector, can face challenges and downturns at times. Here are some factors that may contribute to what could be considered a “dark time” for the auto components industry in India:

- Economic Slowdown: Economic slowdowns, both domestically and globally, can impact consumer demand for automobiles, leading to reduced production volumes. This, in turn, affects the demand for auto components, leading to lower sales and profitability for component manufacturers.

- Volatility in Raw Material Prices: Fluctuations in the prices of raw materials such as steel, aluminum, rubber, and plastics can significantly impact the cost structure of auto component manufacturers. Sudden increases in raw material prices without corresponding increases in selling prices can squeeze profit margins and strain the financial health of companies.

- Disruptions in Supply Chains: Any disruptions in the supply chain, whether due to natural disasters, geopolitical tensions, or logistical challenges, can affect the timely availability of raw materials and components for auto component manufacturers. This can lead to production delays, increased costs, and customer dissatisfaction.

- Regulatory Changes: Changes in regulatory requirements related to safety standards, emissions norms, or import/export regulations can necessitate costly upgrades or modifications to manufacturing processes and products. Compliance with these regulations may impose additional burdens on auto component manufacturers, especially smaller firms with limited resources.

- Technological Disruption: Rapid advancements in automotive technology, such as electrification, autonomous driving, and connectivity, can disrupt traditional auto component manufacturing processes and product portfolios. Companies that fail to adapt to these technological shifts risk becoming obsolete in the market.

- Intense Competition: The auto components industry in India is highly competitive, with numerous players vying for market share. Price wars, aggressive marketing tactics, and undercutting by competitors can erode profitability and create a challenging business environment for industry participants.

- Shifts in Consumer Preferences: Changes in consumer preferences, such as a preference for electric vehicles, shared mobility solutions, or alternative modes of transportation, can impact the demand for certain types of auto components. Manufacturers may need to pivot their product offerings to align with changing market dynamics.

- Global Economic Factors: Global economic factors, such as trade tensions, currency fluctuations, and geopolitical uncertainties, can have ripple effects on the Indian economy and, consequently, on the auto components industry. Uncertain economic conditions can dampen investor sentiment and business confidence, leading to reduced investments and slower growth.

During such challenging times, auto component manufacturers may need to focus on cost optimization, operational efficiency, product diversification, innovation, and strategic partnerships to weather the storm and emerge stronger in the long run. Government support through favorable policies, incentives, and infrastructure development can also play a crucial role in revitalizing the industry.

The Indian Auto Components Industry: A Story of Growth and Transformation

The Indian auto components industry has come a long way, evolving from an import-dependent sector to a global player. Here’s a summary of its key aspects:

Growth Trajectory: The industry has witnessed impressive growth, contributing significantly to India’s GDP and job creation.

Focus on Innovation: Continuous adaptation to meet the demands of new technologies like electric vehicles and stricter emission regulations is crucial.

Global Presence: India has emerged as a major exporter of auto components, catering to a diverse international market.

Skilled Workforce: A large pool of skilled engineers and technicians forms the backbone of the industry’s production capabilities.

The Future Landscape:

EV Revolution: The rise of electric vehicles presents both challenges and opportunities. Adapting to EV component production and navigating a disrupted aftermarket will be crucial.

Technological Advancements: Continuous innovation in areas like autonomous vehicles and connected car technologies will shape the future of the industry.

Collaboration: Collaboration between the auto component industry and the transportation sector is essential for developing sustainable and efficient transportation solutions.

Conclusion:

Despite the challenges, the Indian Auto Components industry is well-positioned for continued success. By embracing innovation, skilling its workforce, and capitalizing on the EV revolution, the industry can solidify its place as a global leader in the years to come.

Click and follow for regular warehousing Upgraded Updated news report :- Please Click

Merger and Acquisition Group for efficiently Cost Optimisation :- Join (Investing Budget Min 10 Crore INR)

Warehousing Development and Regulatory Authority :- www.wdra.gov.in

India Logistics & Supply Chain Association (ILSCA) :- www.aplf.net

Federation of Cold Storage Associations of India FCAOI :- www.fcaoi.org

Central Warehousing Corporation :- www.cewacor.nic.in

ACMA The Automotive Component Manufacturers Association of India :-www.acma.in

Society of Indian Automobile Manufacturers :-www.siam.in

NOTE :- From our point of view, the biggest problem today is that due to mistrust, disagreement, insecurity, today the price of our business and daily essential commodities and raw materials is increasing infinitely unnecessary.We have a small effort which is expected that every good buyer should get a good seller without a middleman and a good seller gets a good buyer.We always provide advanced information on our behalf to our customers. If you are interested in public interest by the presentation and renewal of your business, then share with us by people what revolutionary changes you have made to your business that have benefited the people.So that our good business community and you also benefit forever. And people should benefit so that a good business environment is created.

Advantage Our Pro Membership :-We provide advanced support to our pro membership clients in Transportation, Logistics, Warehousing, Finance etc….

Recommended :-

- Please click and See Our Endless Journey – Please Click

- Manufacturer association in India – AIAI India ( www.aiaiindia.com )

- Merchants manufacturer industries manufacturing companies

- Difference between sales and marketing

- Fraud Cases and Examples in Business

- Business Problems and Solutions

Frequently asked questions (FAQs):-

Who is the largest auto parts supplier in India?

local – motherson and global bosch

What is auto spare parts?

The different types of Auto spare parts are:

Auto Electrical Parts. Starters, Armatures, Commutators, Field Coils,

Nuts & Bolts. Hub Bolts, T- Bolts, Washers, Nuts,

Transmission Parts. Gears, Tie-Rod Ends, Ball Joints, U-J Cross.

Brake Parts & Rubber Components. Brake Hoses, Fuel Lines, Engine Mountings, Supports

How many components are in a car?

A single car has about 30,000 + spare parts, counting every part down to the smallest screws, nuts and bolts. Some of these parts are made by the manufacturer, but there are lots of suppliers that make many of these parts. The 30,000 or so parts use different raw materials and different manufacturing processes.

What is automobile and types?

An Automobile is a self propelled vehicle which contains the power source for its propulsion and is used for carrying passengers and goods on the ground, such as car, bus, trucks, etc

How do I start my own car spare parts?

15 Genuine Steps to Starting an Auto Parts Manufacturing Business

Research

Get a Business Plan

Seek out a support system

Come Up With Partnerships

Get the legal details sorted out

Get a great Location

Seek Funding For Your Auto Parts Manufacturing Business

Find the right factory

Assess Competitors

Put together a great team

Your Business model

Consider daily operations

Have A Working Plan

Consider diversification

Take baby steps

What is OEM in manufacturing ?

An original equipment manufacturer (OEM) traditionally is defined as a company whose goods are used as components in the products of another company, which then sells the finished item to users.

What are the types of spare parts?

Genuine Original Equipment Parts

Replacement Parts

Aftermarket Parts

Re manufactured Parts.

Reconditioned Parts.

Salvaged Parts

What are mechanical parts of a car?

Including Block, Heads, Pistons & Valves. Cooling System: Including Radiator, Thermostat, Water Pump, Heater & Hoses. Charging System: Including Alternator, Regulator & Battery. Ignition System:Includes Spark Plugs, Distributor, Ignition Wires & Coil.

How are automobiles classified?

Based on the Number of Wheels the Vehicle Has:

Automobiles can be classified as the number of wheels an automobile vehicle has, for example: Two Wheeler Vehicle (Motor Cycle, Scooty). Three Wheeler Vehicle (Auto, Toto, etc.). Four Wheeler Vehicle (Cars, Bus, Truck, Tractor, etc.)

What are automobiles?

Automobile, byname auto, also called motorcar or car, a usually four-wheeled vehicle designed primarily for passenger transportation and commonly propelled by an internal-combustion engine using a volatile fuel.

How many types of automobile engineering are there?

There are mainly three types of automotive engineers: Design Engineers: They are responsible for the design aspect of a vehicle. Simply put, they make the vehicle look good. Design engineers primarily work toward developing the visual appearance of a vehicle and also are involved in the concept design.

What are safety devices in a car?

Here’s a rundown of some basic safety gear.

Airbags. Front airbags have been standard on all new cars since 1998 and light trucks since 1999.

Antilock brakes (ABS)

Traction control.

Electronic stability control.

Safety-belt features. …

Newer safety features – accident avoidance systems.

Tire-pressure monitors.

Telematics.

What is the best automotive business to start?

Here is a list of some Profitable Automobile Business Ideas

Mobile Oil Change Service Business.

Mobile Car Wash Business.

Automobile Service Station.

Tire Store Retail Business.

Battery Reconditioning Business.

Auto-Body Store.

Tow Trucking Service.

Spare Parts Distribution.

automobile industry a small scale industry?

Indian automotive sector today is a $74 billion industry and by 2026, the industry is expected to achieve a turnover of $300 billion- clocking a CAGR of ~ 15 percent. In India, the small-scale automobile business is considered as a small business opportunity for rural, suburban, and metro cities.

How much does it cost to start a auto parts store?

With most automotive franchises, budget anywhere from $20,000 to $50,000. Auto maintenance and repair shops usually have an initial franchise fee of $20,000 to $30,000. Tire stores often range from $25,000 to $30,000.

What do you need to start a business?

Conduct market research. Market research will tell you if there’s an opportunity to turn your idea into a successful business.

Write your business plan.

Fund your business.

Pick your business location.

Choose a business structure.

Choose your business name.

Register your business.

Get federal and state tax IDs.

What is OEM good or bad?

Original Equipment Manufacturer (OEM) parts are built by the company that initially made the parts for the auto manufacturer. The OEM parts we carry are precisely the same as the part that came with your car. OEM parts are just as reliable as genuine parts, but you get them for a better value .

Which analysis is used for spare parts?

Spares Analysis is a tool that uses delivery time and cost, downtime, lost production costs, and failure and repair data to calculate the amount of spare parts you need to keep at any specific time.

How do you find critical spare parts?

To determine what parts need to be held on site as critical or insurance spares, a criticality analysis of the maintainable assets is conducted to rank the probability of impact on the production process or employee safety if the equipment were to fail.

How many screws are in a car?

in car with 3,500

Who is the number 1 car company in the world?

As per budget Tesla ,Toyota,Volkswagen

What is the most important part of a car?

The most important mechanical part of the car vehicle is engine undoubtedly because it acts a heart for your car where it makes sure that all the gasoline that is correctly pumping into the tank and turning into the mechanical energy or not.

What is auto mobile business?

The auto-body store business is providing services of auto-body repairing and new bodybuilding as well as selling spare parts and accessories related to the vehicle body. As the numbers of the vehicle are growing, the business opportunity of auto-body store is also increasing globally.

What are auto accessories?

These auto accessories include, dash covers, seat covers, mirrors, shifter knobs, steering wheel covers, fuel consumption meters, window tint, stereo system, DVD players, floor mats and even air fresheners. Car seat covers can be purchased at any store or auto store and they come in different materials.

What are the types of spare parts?

What Types of Spare Parts are There? Genuine, OEM, Aftermarket and Used Parts Explained.

Genuine Original Equipment Parts.

Replacement Parts.

Aftermarket Parts.

Remanufactured Parts.

Reconditioned Parts.

Salvaged Parts

How old is the world’s oldest car?

The oldest functioning car is La Marquise, a steam-powered, four-wheeled, four-seater vehicle, manufactured by De Dion Bouton et Trépardoux (France) in 1884; three years later it won the world’s first automobile race, powering along the 30.5-km (19-mile) track at an average of 42 km/h (26 mph) from Paris to Neuilly,

What are auto accessories?

These auto accessories include, dash covers, seat covers, mirrors, shifter knobs, steering wheel covers, fuel consumption meters, window tint, stereo system, DVD players, floor mats and even air fresheners. Car seat covers can be purchased at any store or auto store and they come in different materials.

What is the rarest car in the world?

The rarest car in the world is Ferrari 250 Grand Turismo Omologato, a rare diamond designed and cared for by Enzo Ferrari in personam. In June 2018, the 1964 Ferrari 250 GTO became the most expensive car in history, setting an all-time record selling price of $70 million.

What’s the oldest car that still works?

The 1884 De Dion-Bouton Et Trepardoux Dos-A-Dos Steam Runabout is the world’s oldest car that is still running and drivable. Built for the French Count de Dion in 1881 and later nicknamed “La Marquise,” the steam-powered car is only nine feet long and weighs 2,100 pounds.

Which car brand is best?

Toyota ,Tata

What is the main component of engine?

For a four-stroke engine, key parts of the engine include the crankshaft (purple), connecting rod (orange), one or more camshafts (red and blue), and valves. For a two-stroke engine, there may simply be an exhaust outlet and fuel inlet instead of a valve system.

What are the two main types of engine?

We can broadly classify engines into two categories those are Internal Combustion Engine and External Combustion Engine.

What is the most common engine type?

Inline engines are the most common form of engine, and are found on most hatchbacks and small family cars.

What car parts break down most?

Brake lights, turn signals, taillights, and other small external lights are car parts that tend to fail more often than headlights

Which car has the cheapest spare parts?

TATA

Why are auto parts so expensive?

The main reason is probably “because they can be” – you buy your car, a few years later, part of it breaks, and you really need it to fix it so it works properly. You need the parts, so the car company can charge a higher price for them – because not buying the part isn’t an option.

Which car is best for daily use?

Tata Tiago, Maruti WagonR, Honda Jazz, Maruti Swift and Dzire, Renault Kwid, Hyundai Santro, etc are best cars for daily use and city driving.

What is the best car for a handicap?

The 5 best cars for people with disabilities

Ford C-Max: A comfortable car for both driver and passenger.

Mercedes-Benz V-Class: For the independent driver with a large family.

Volkswagen Caddy: Easy to enter, best all-around car for adaptations.

Toyota Yaris: For the city-living independent driver or passenger.

What is the number 1 safest car?

Safest Cars after 2020:

Toyota Camry.

Honda Odyssey.

Nissan Maxima.

Tesla Model 3.

Acura TLX.

Volvo S60 and V60.

Lexus ES.

Audi A6.

How can I make my car look nicer?

8 Cheap Ways To Improve The Look Of Your Car

Invest in a new set of seat covers.

Replace your floor mats.

Get the seats and carpets shampooed.

Get a new stereo unit or AUX port.

Invest in quality paint.

Replacement of worn out and old tyres.

Repair dents and scratches.

Perform regular maintenance checks.

Which is the No 1 car in the world?

Bugatti Veyron Mansory Vivere: An exclusive edition of Bugatti Veyron, the Mansory Vivere can be yours at just Rs 30 crore. The engine has an earth-shattering power of 1200 hp and claims a top-speed of 406 kmph. This is one of the fasted Bugatti ever built and has already been sold out worldwide.

What is the future of auto components and spare parts manufacturing companies?

After the news of electric vehicles, the future of other vehicle companies and spare parts manufacturing organisations looks bleak.

Whats contribution auto components business in Indian economy and GDP ?

The auto components industry accounted for 2.3% of India’s Gross Domestic Product (GDP) and 25% to its manufacturing GDP, providing employment to 50 lakh people .

What were the changes in the auto component business after the corona disease?

The condition of auto components business has become very pathetic after corona disease.