🏗️ The Story of PEB Structures – Born from a Dream

Long ago, construction was slow, heavy, and expensive. Every building — whether a factory, warehouse, or school — had to be made brick by brick, stone by stone. It was a tiring process, and industries often waited for months before they could even begin operations.

But in the late 1960s, a group of engineers in the United States began to dream differently. They asked themselves:

👉 “Why should buildings always take so much time? Why can’t we build them like machines — designed in parts, made in factories, and assembled quickly at the site?”

This simple but powerful question gave birth to the Pre-Engineered Building (PEB).

🌟 The First Spark

One of the pioneers, Butler Manufacturing in the USA, dared to try something bold: they pre-designed the steel frames, beams, and columns in a factory and carried them to the construction site. Like giant Lego blocks, these pieces were put together in days — not months.

For the first time, people saw that a building didn’t need to be a slow project. It could be fast, strong, flexible, and cost-effective.

🌍 Why the World Needed PEB

The 1970s were an age of growth — factories, airports, warehouses, and schools were needed everywhere. Traditional construction was too slow to match the speed of industrialization.

PEB was invented because industries wanted:

- Speed — to set up plants and warehouses quickly.

- Strength — to withstand time and weather.

- Flexibility — to expand whenever needed.

- Savings — to cut down on labor and material costs.

The world needed a better way to build — and PEB was the answer.

🚀 How It Spread Across the World

From America, the idea traveled quickly to Asia, Middle East, and India. Soon, giant warehouses, logistic hubs, malls, and even schools started rising with the magic of pre-engineering.

PEB didn’t just save money or time — it gave industries the power to dream bigger, to scale faster, and to compete globally.

💡 The Lesson Behind the Story

The story of PEB is more than engineering — it’s about vision and courage.

It tells us that:

- Every problem carries the seed of innovation.

- Asking bold questions can change entire industries.

- True progress is built not just with steel and bolts, but with imagination and ambition.

So whenever you see a grand warehouse, a smart logistics park, or a modern factory made of PEB, remember this:

👉 It is not just a structure. It is a story of human willpower to build faster, stronger, and smarter.

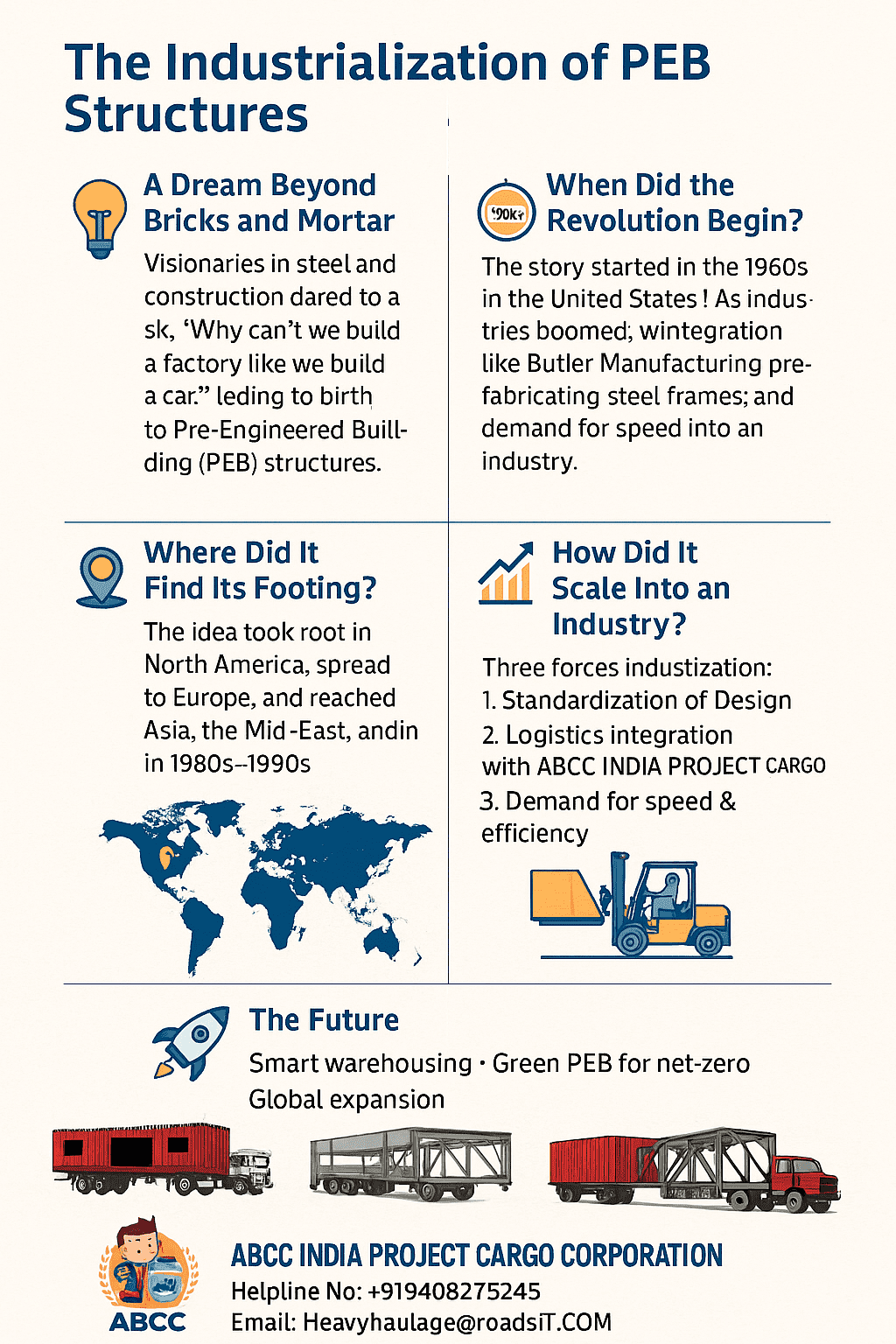

🏗️ The Industrialization of PEB Structures – When, Where & How It Happened

🌟 A Dream Beyond Bricks and Mortar

Decades ago, construction was slow, costly, and unpredictable. A factory needed months to rise, a warehouse consumed years of planning, and every building felt like reinventing the wheel.

But a few visionaries in the steel and construction industry dared to ask:

👉 “Why can’t we build a factory like we build a car — designed in advance, manufactured in parts, and assembled quickly?”

That single question changed the face of construction forever. It gave birth to what we proudly call today Pre-Engineered Building (PEB) Structures.

🕰️ When Did the Revolution Begin?

The story of PEB industrialization began in the 1960s in the United States. At that time, industries were booming, but conventional construction was holding them back.

Engineers and entrepreneurs realized the gap: industry needed speed and strength, but traditional construction offered slowness and uncertainty.

Enter pioneers like Butler Manufacturing, who began pre-designing and pre-fabricating steel frames, trusses, and panels in controlled factory environments. Instead of dragging construction for months on-site, they brought ready-made components and assembled them in weeks.

It was a bold experiment that worked — and an industry was born.

🌍 Where Did It Find Its Footing?

The idea first took root in North America and quickly spread to Europe. By the 1970s, PEB was already transforming warehouses and factories.

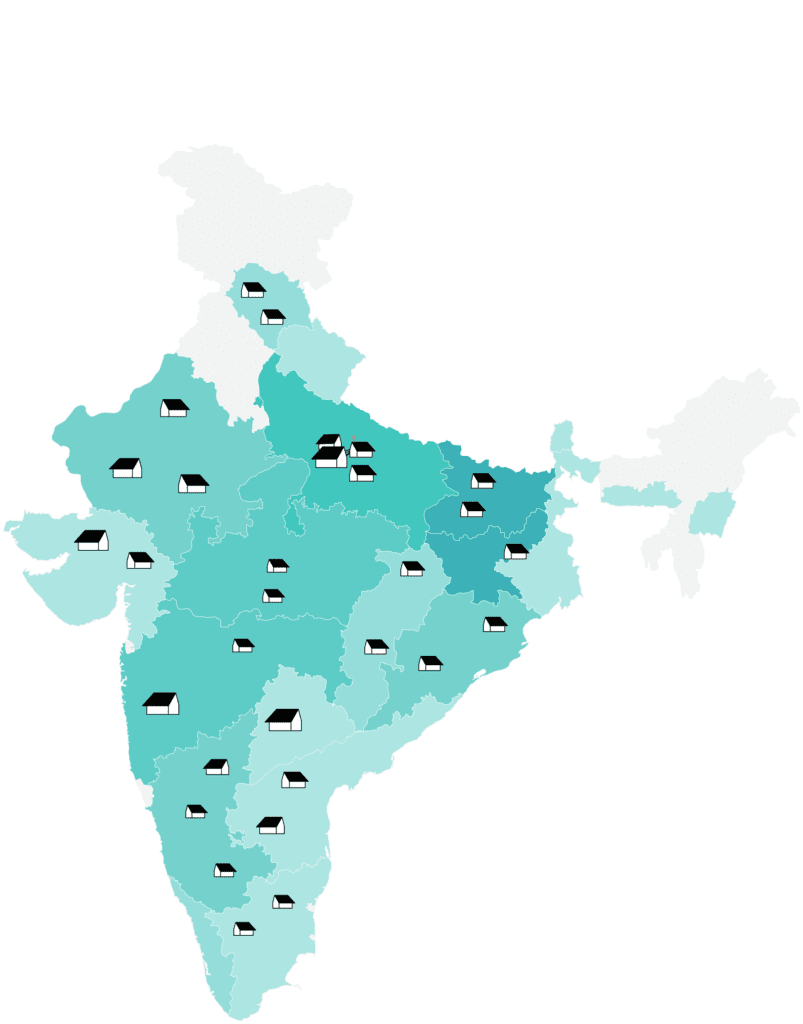

But the true industrialization happened when the model reached Asia, the Middle East, and India in the 1980s–1990s.

- In the Middle East, PEB became the choice for airports, malls, and oil infrastructure.

- In India, it revolutionized logistics hubs, cold storage, schools, showrooms, and even retail spaces.

- Across Asia-Pacific, PEB fueled fast-growing economies that couldn’t afford the delays of traditional building.

Wherever there was industrial ambition, PEB became the trusted partner.

⚙️ How Did It Scale Into an Industry?

The industrialization of PEB didn’t happen overnight. It was powered by three forces that aligned perfectly:

Standardization of Design

Computer-aided engineering made it possible to create modular, customizable designs.

No two PEBs had to look the same, yet they all followed quick, scalable models.

Logistics Integration

Specialized transporters, like ABCC INDIA PROJECT CARGO CORPORATION, enabled the movement of massive steel structures across states and borders.

Without this backbone, PEB could not have scaled globally.

Demand for Speed & Efficiency

Industries, governments, and private sectors wanted results fast.

PEB promised weeks instead of months, and the world embraced it wholeheartedly.

Thus, the small spark of an idea turned into a full-scale industrial revolution in construction.

📈 The Impact That Changed Everything

The rise of PEB transformed more than just buildings — it reshaped entire industries:

- Factories launched faster, reducing time-to-market for products.

- Warehouses expanded quicker, fueling global supply chains.

- Costs dropped, thanks to efficiency in labor and material use.

- Durability improved, as steel-framed buildings lasted longer with less maintenance.

- Sustainability became real, with recyclable steel and reduced waste.

PEB became a symbol of progress, resilience, and intelligent industrialization.

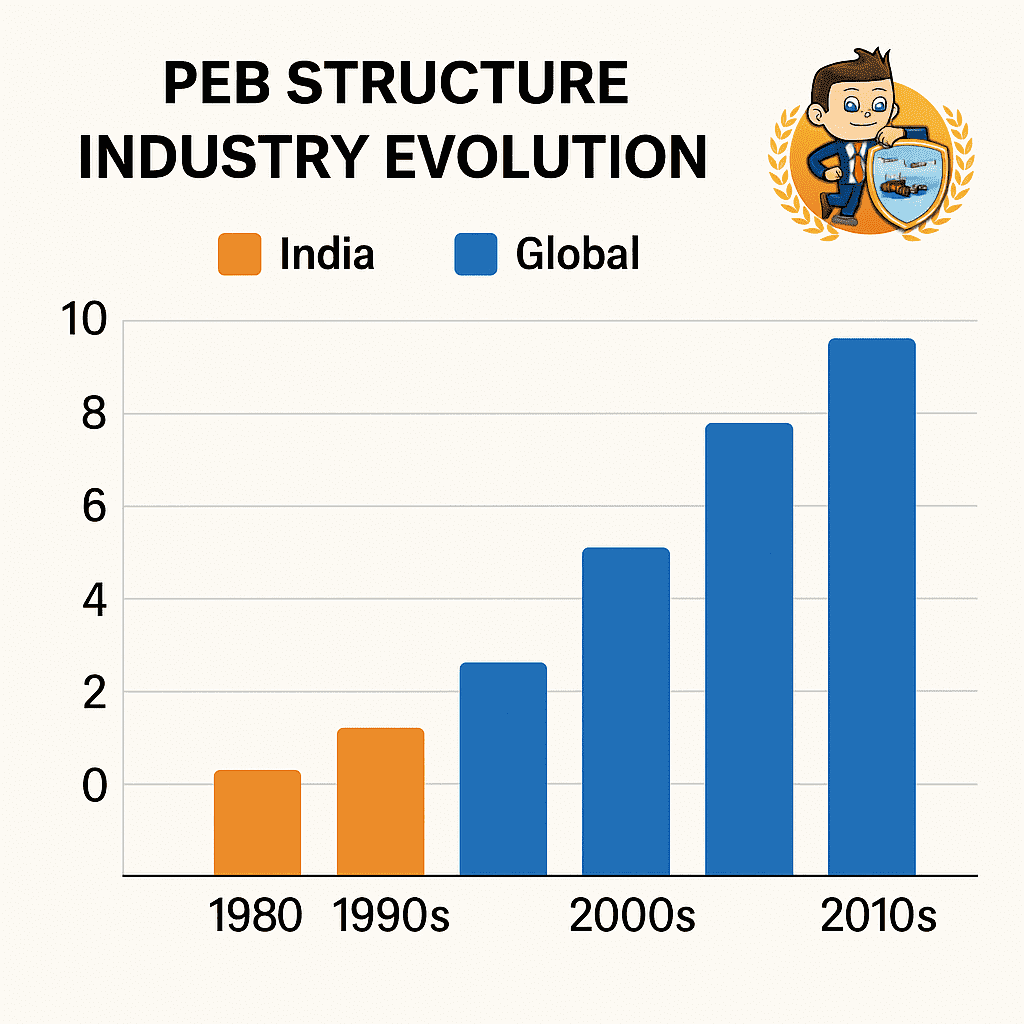

🚀 Evolution Over the Decades

Like every great idea, PEB has evolved with time:

- 1960s – Early experiments with pre-engineered frames.

- 1970s – Industrial-scale adoption in the USA and Europe.

- 1980s–90s – Expansion to Asia and the Middle East.

- 2000s – Integration of CAD/CAM design, coatings, and insulation systems.

- 2010s – Green buildings, solar-ready roofs, and energy-efficient PEBs.

- 2020s – Smart PEB with IoT sensors, predictive maintenance, and digital monitoring.

From a simple idea, PEB has grown into a global industry worth billions, redefining how we imagine construction.

🔮 The Future of PEB Structures

Looking ahead, the story of PEB is still unfolding. The next chapters promise:

- Smart Warehousing with AI and IoT monitoring.

- Green PEB for net-zero energy consumption.

- Global Expansion as developing nations adopt faster construction.

- Heavy-Haul Transport Growth, where leaders like ABCC INDIA PROJECT CARGO CORPORATION ensure massive PEB components reach even remote industrial hubs.

The future belongs to those who value speed, sustainability, and smart innovation — and PEB delivers all three.

💡 The Leadership Lesson in This Story

The industrialization of PEB is more than engineering history — it’s a leadership lesson for every entrepreneur and corporate leader:

👉 Innovation is not about asking “Can it be done?” but about asking “How can we do it better?”

PEB reminds us that courage to rethink the ordinary can reshape industries, create new markets, and inspire generations.

Just as engineers turned steel into speed, you too can turn ideas into industries.

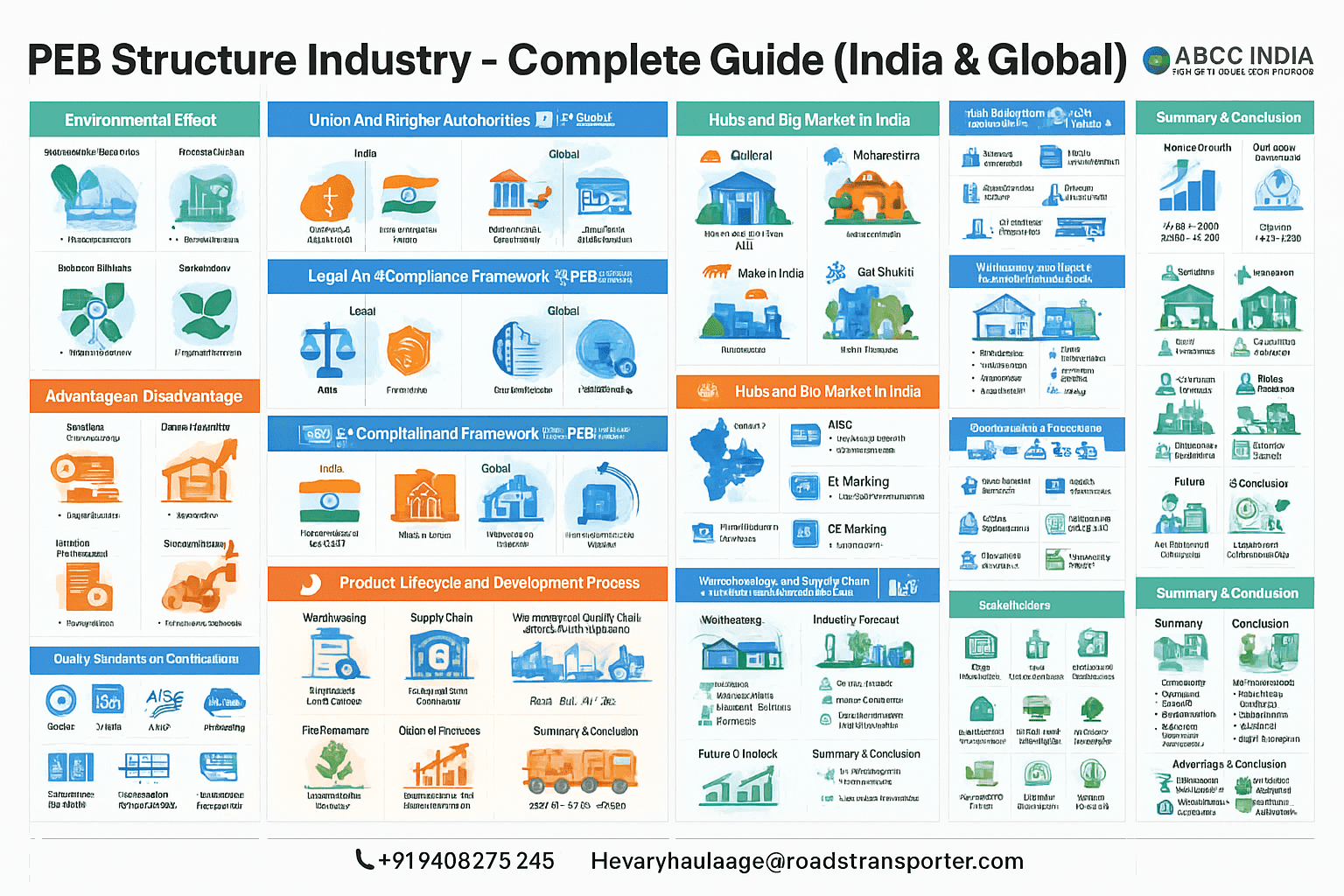

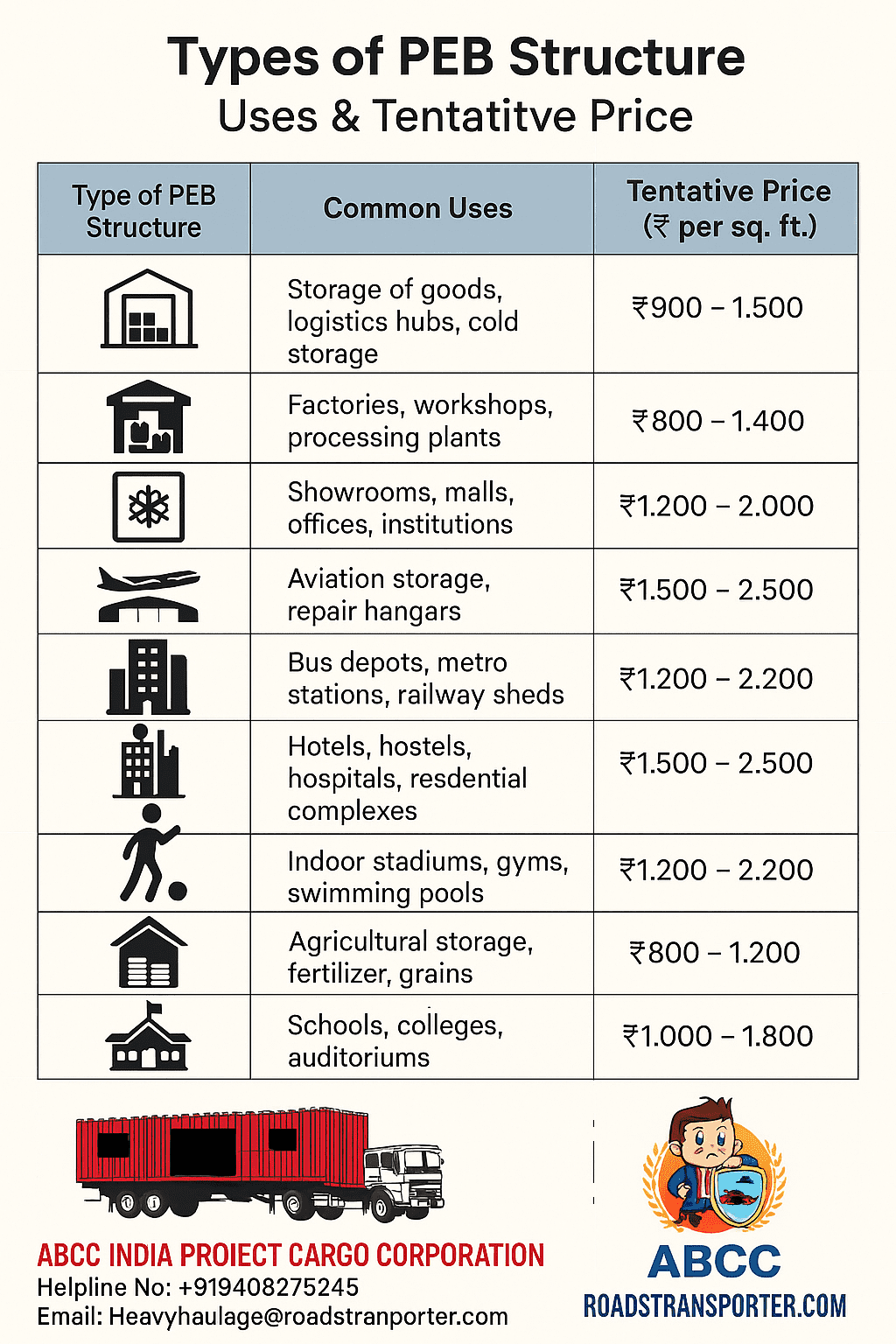

Types of PEB Structures – Uses & Tentative Price Range

| Type of PEB Structure | Common Uses | Tentative Price Range (₹ per sq. ft.) | Notes / Highlights |

|---|---|---|---|

| PEB Warehouses | Storage of goods, logistics hubs, cold storage | ₹900 – ₹1,500 | Most popular; customizable for FMCG & e-commerce |

| PEB Industrial Sheds | Factories, workshops, processing plants | ₹800 – ₹1,400 | Strong demand in manufacturing sector |

| PEB Commercial Buildings | Showrooms, malls, offices, institutions | ₹1,200 – ₹2,000 | Aesthetic designs with glass/steel combinations |

| PEB Cold Storage Units | Agro-produce, pharma, food processing | ₹1,200 – ₹1,800 | Requires insulation & refrigeration add-ons |

| PEB Aircraft Hangars | Aviation storage, repair hangars | ₹1,500 – ₹2,500 | Large clear spans, heavy-duty steel |

| PEB Metro/Rail Sheds | Bus depots, metro stations, railway sheds | ₹1,200 – ₹2,200 | Heavy load-bearing structures |

| PEB Multi-Storey Buildings | Hotels, hostels, hospitals, residential complexes | ₹1,500 – ₹2,500 | Faster construction vs. RCC buildings |

| PEB Sports Complexes | Indoor stadiums, gyms, swimming pools | ₹1,200 – ₹2,200 | Large span coverage without columns |

| PEB Godowns | Agricultural storage, fertilizer, grains | ₹800 – ₹1,200 | Rural/agri use, cost-effective option |

| PEB Schools/Institutions | Schools, colleges, auditoriums | ₹1,000 – ₹1,800 | Quick build for educational infra |

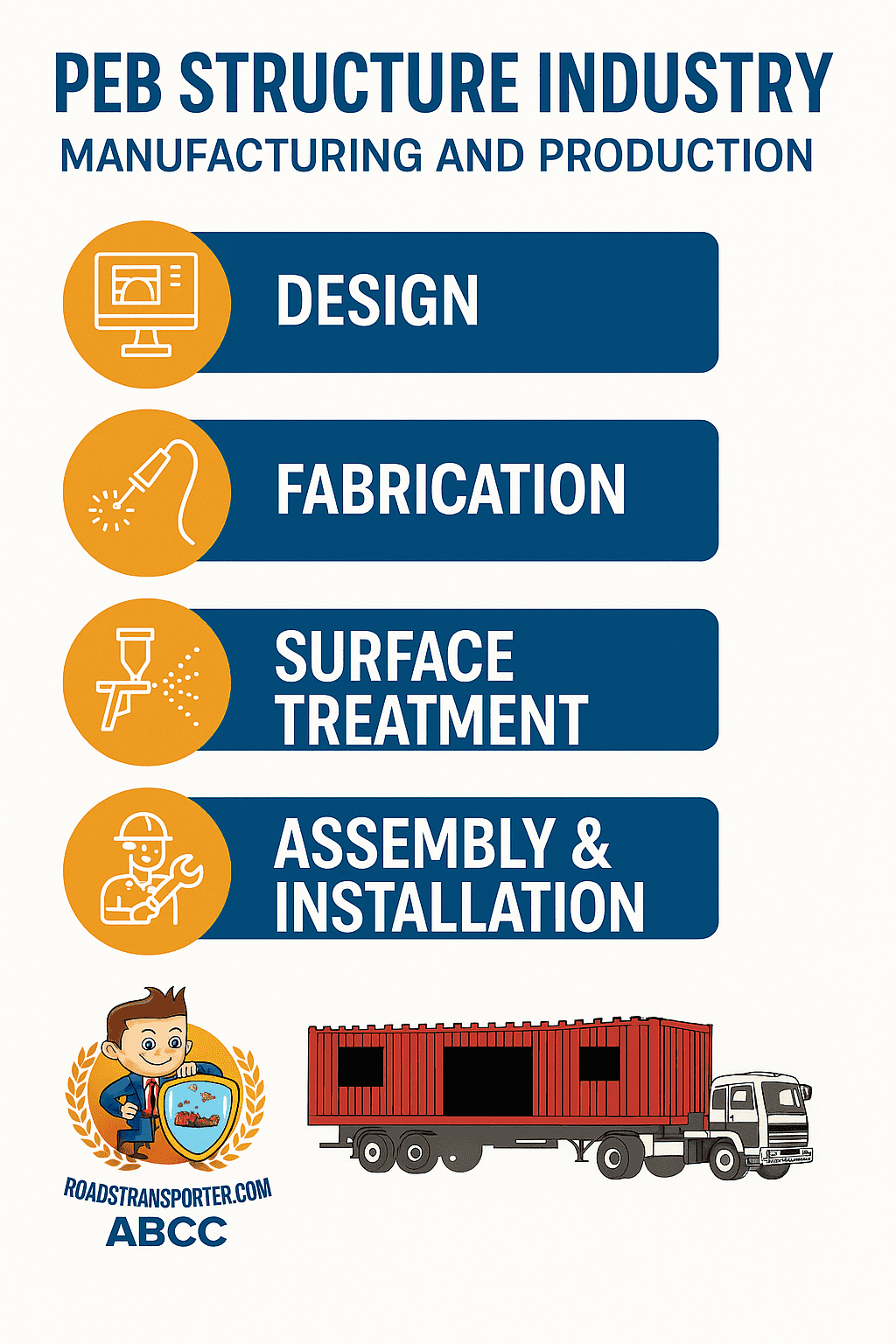

🏗️ PEB Structure Industry – Manufacturing & Production Structure

| Stage / Process | Activities Involved | Key Equipment / Technology | Importance to Industry |

|---|---|---|---|

| 1. Design & Engineering | CAD modeling, load analysis, architectural layouts | CAD/CAM, BIM software | Ensures precision & custom requirements |

| 2. Material Procurement | Sourcing steel, roofing sheets, insulation materials | Steel plants, global supply chain | Quality steel ensures durability |

| 3. Steel Fabrication | Cutting, welding, drilling, painting of steel members | CNC machines, plasma cutters, robotics | Shapes the backbone of PEB structure |

| 4. Component Manufacturing | Columns, rafters, purlins, trusses pre-engineered | Automated assembly lines | Reduces errors, improves consistency |

| 5. Surface Treatment | Painting, galvanizing, anti-corrosion coatings | Spray booths, galvanizing baths | Enhances life span & weather resistance |

| 6. Quality Inspection | Load testing, weld checks, dimensional accuracy checks | NDT testing, ultrasonic scanners | Safety and compliance assurance |

| 7. Packaging & Dispatch | Bundling, labeling, safe loading for transport | Forklifts, cranes, trailers | Ready for logistics & timely delivery |

| 8. Transportation | Moving heavy & oversized PEB components to site | ODC trailers, multi-axle trucks (ABCC) | Key role of heavy haul logistics firms |

| 9. On-site Assembly | Erection of frames, roofing, cladding, finishing | Cranes, boom lifts, skilled workforce | Converts factory-made parts into a site-ready structure |

| 10. Handover & Maintenance | Final audit, client handover, AMC services | Inspection tools, service teams | Ensures client satisfaction & longevity |

🏗️ PEB Structure Industry – Evolution (India vs. Global)

| Time Period / Phase | Global Evolution Highlights | India Evolution Highlights |

|---|---|---|

| 1960s – Birth of PEB | USA pioneers like Butler Manufacturing introduce PEB | Limited awareness in India; traditional RCC rules |

| 1970s – Early Growth | PEB spreads to Europe for factories & warehouses | Some steel shed adoption for industries |

| 1980s – Expansion | PEB expands to Middle East (airports, malls, oil infra) | Indian industry starts testing PEB for workshops |

| 1990s – Industrialization | Asia-Pacific adopts PEB for speed & cost benefits | Entry into India’s manufacturing clusters (Gujarat, Maharashtra, Tamil Nadu) |

| 2000s – Standardization | CAD/CAM, coatings, insulation boost global PEB | Major Indian players emerge (Kirby, Tata Bluescope) |

| 2010s – Modernization | Smart PEB with IoT, energy-efficient coatings | Warehouses, logistics parks, malls, schools adapt PEB |

| 2020s – Sustainability Era | Net-zero energy, solar-ready, recyclable steel focus | Cold storage, logistics hubs, smart infra powered by PEB |

| Future – 2030 & Beyond | AI-driven warehouses, net-zero global standardization | India projected to be 3rd largest PEB market by 2030 |

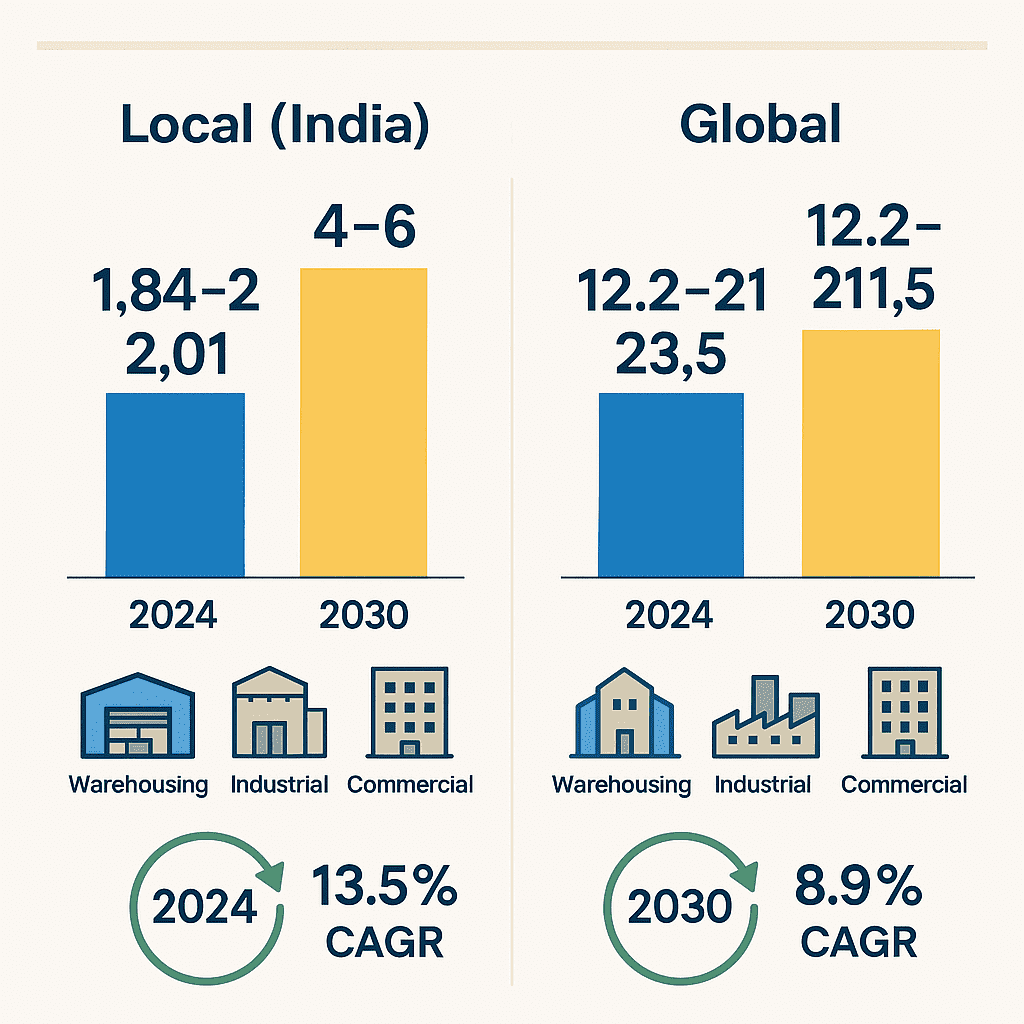

GLOBAL PEB MARKET SNAPSHOT (USD Billion)

| Metric | Value / Range | Notes |

|---|---|---|

| 2024 size | 12.2 – 21.5 | Different methodologies across firms. |

| 2030 forecast | 32.6 | Grand View Research outlook summarized via GII (to 2030). |

| 2033 forecast | 32.8 | IMARC global forecast. |

| 2034 forecast | 57.8 | Precedence Research (higher-end scenario). |

| CAGR (’25–’30/’33) | ~8.5% – 11.8% | Range across sources. |

| Top regions | APAC leads (≈35% share, 2024) | Structural steel intensity + industrial build-outs. |

| Key demand pockets | Warehousing & logistics, manufacturing sheds, data centers, retail/commercial shells | Sectors consistently cited as fastest adopters. |

INDIA PEB MARKET SNAPSHOT (USD Billion)

| Metric | Value / Range | Notes |

|---|---|---|

| 2024 size | 1.84 – 2.01 | GVR India: 1.84; IMARC India: 2.01. |

| 2030 forecast | 3.93 | GVR India outlook. |

| 2033 forecast | 6.33 | IMARC India outlook. |

| CAGR (’25–’30/’33) | ~13.5% / 12.5% | GVR (’25–’30) / IMARC (’25–’33). |

| Leading applications | Industrial buildings (largest), commercial fastest-growing | 2024 base + forward view. |

| Macro tailwinds | Manufacturing capex, 3PL/4PL warehousing, e-commerce fulfillment, steel availability | Sector commentary across sources. |

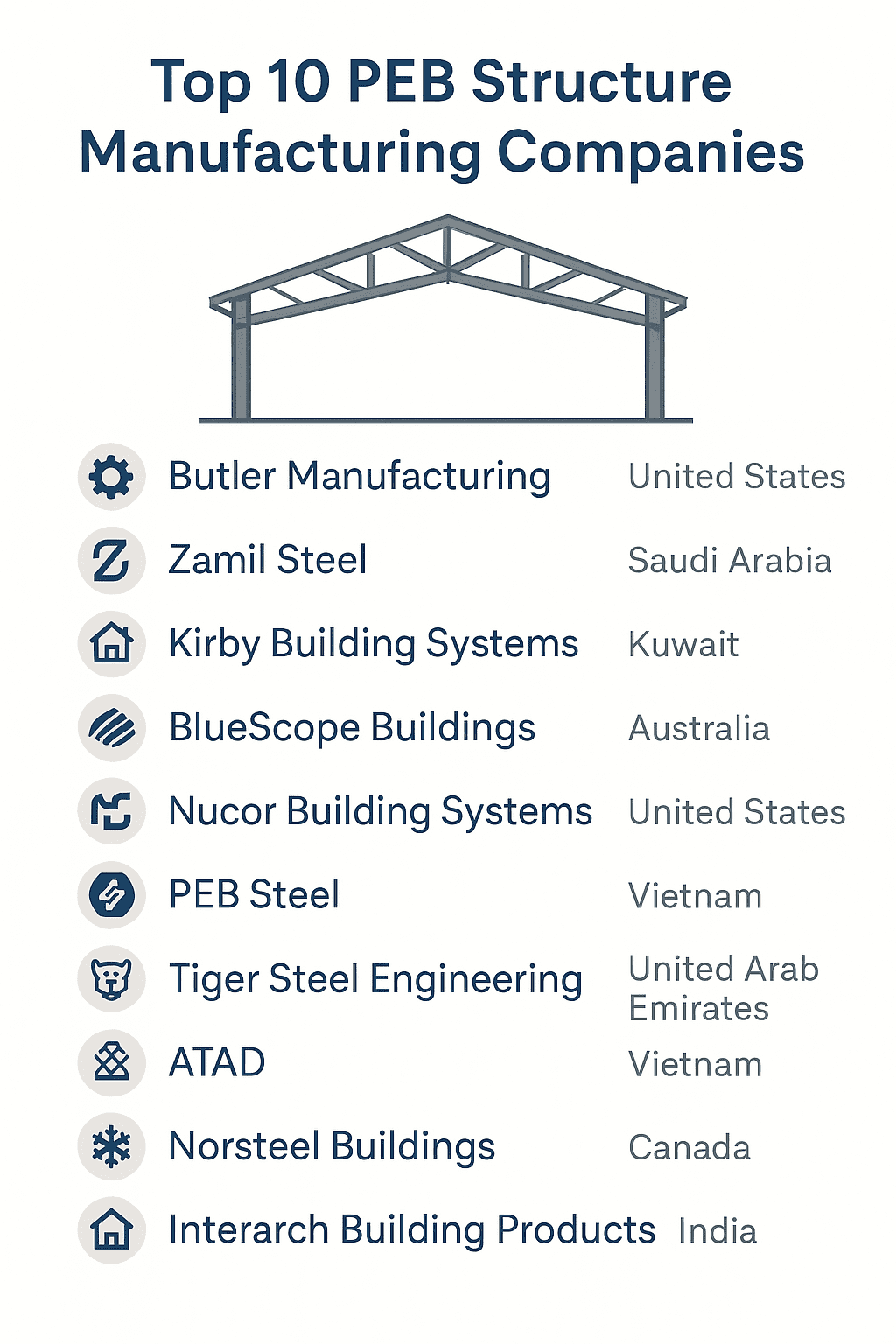

🏗️ Top 10 PEB Structure Manufacturing Companies

| Company | Country | Founded | Specialization | Unique Strength | Motivational Lesson |

|---|---|---|---|---|---|

| Butler Manufacturing | USA | 1901 | Pioneer of PEB systems, roofing & cladding | First all-steel building system, MR-24® roof | Innovation creates legacy – small workshop ideas can become global industries. |

| Zamil Steel | Saudi Arabia | 1977 | PEBs for Middle East, Africa, Asia | One of the world’s largest PEB plants, 90+ countries served | Align with national transformation – ride the wave of regional modernization. |

| BlueScope Buildings | Australia / USA | 1885 (as Lysaght), 2002 (BlueScope Steel) | Global PEB systems under Butler, Varco Pruden, etc. | COLORBOND®, ZINCALUME® sustainable steel | Partnerships multiply power – merging heritage with innovation creates global reach. |

| Kirby Building Systems | Kuwait / India | 1976 | PEBs for industrial sheds, warehouses | 70+ countries, early mover in India (1999 plant) | Timing is everything – early entry into fast-growing markets builds dominance. |

| Tata BlueScope Steel | India | 2005 (Tata–BlueScope JV) | Roofing, cladding, PEB solutions | COLORBOND®, ZINCALUME® steel, BUTLER® systems | Trust + innovation = impact – partnerships rooted in values create long-term success. |

| Nucor Building Systems | USA | 1987 | Customized steel building systems | Employee-centric, sustainable steel (scrap recycling) | People are the foundation – culture and trust drive resilience and growth. |

| Everest Industries | India | 1934 | Roofing, boards, panels, PEB | Diversified from roofing to modern PEB solutions | Reinvention is survival – adapt legacy companies to stay relevant. |

| PEB Steel Buildings Co. Ltd. | Vietnam / Asia | 1994 | PEB solutions for Asia, Middle East | Regional manufacturing capacity, 70+ countries served | Emerging markets can lead – global relevance is possible with quality + resilience. |

| Qatar Steel Industries Factory | Qatar | 1980 | PEBs, structural steel, towers | Key role in FIFA 2022 projects, aligned with Vision 2030 | National ambition creates opportunity – align your mission with your country’s progress. |

| Lindab Group | Sweden / Europe | 1959 | Roofing, cladding, ventilation, PEB | Sustainability pioneer, design + efficiency | Sustainability is advantage – eco-friendly innovation builds long-term legacy. |

Butler Manufacturing (USA)

The story of Butler Manufacturing is the story of how two brothers’ dream reshaped the way the world builds. Founded in Kansas City in 1901 by Charles and Carl Butler, the company began humbly, supplying standardized roofing panels to local farmers. At a time when construction was slow, laborious, and weather-dependent, their idea was revolutionary — provide pre-engineered components that could be assembled faster, cheaper, and with greater reliability. What began as a small workshop innovation would eventually grow into one of the world’s most influential pre-engineered building companies, and in many ways, the pioneer of the PEB industry itself. The early years were difficult, marked by material shortages, economic downturns, and skepticism from traditional builders. But the Butler brothers persisted. By listening to customers and focusing relentlessly on problem-solving, they laid the foundation of a company culture built on innovation, resilience, and trust.

As the twentieth century advanced, Butler Manufacturing distinguished itself by introducing engineering breakthroughs that pushed the boundaries of what pre-engineered steel could do. The company built the first all-steel building system in 1939, a bold step that positioned it as a leader in modern construction. World War II presented both a challenge and an opportunity. While much of the U.S. economy was disrupted, Butler became a crucial supplier of warehouses, hangars, and military structures for the American war effort. This period tested the company’s adaptability, but also elevated its reputation — when the country needed fast, durable, large-scale construction, Butler was there to deliver. After the war, as the United States entered a golden era of industrialization, Butler seized the moment. Its pre-engineered buildings became the standard for factories, warehouses, and commercial spaces. By offering construction solutions that were faster, more cost-effective, and longer lasting, Butler became synonymous with modern industrial expansion.

Throughout its long history, Butler has thrived because it never stood still. The company introduced the MR-24® Standing Seam Roof, a system that remains an industry benchmark for leak resistance and durability. It mastered modularized building systems, allowing structures to be pre-engineered and erected like an assembly kit. And long before sustainability was a global buzzword, Butler was designing buildings that reduced lifetime energy costs for clients. Each innovation was not about chasing trends but about solving real-world problems — whether that meant withstanding harsh weather, cutting maintenance costs, or accelerating timelines for businesses that needed to grow. These solutions created loyalty among customers and positioned Butler as the trusted partner for both small businesses and large corporations.

Butler’s journey was never without turbulence. The Great Depression, the oil crises of the 1970s, and multiple global recessions tested its financial stability. The steel industry faced volatility in prices, supply chain disruptions, and waves of low-cost competition from Asia. Many firms collapsed or sold off assets. Butler, however, survived and adapted. It diversified beyond PEB into roofing and cladding systems. It doubled down on quality, refusing to cut corners even when the market was flooded with cheaper alternatives. And ultimately, in a strategic move that expanded its global reach, Butler became part of BlueScope Buildings, an Australian steel giant. This partnership gave Butler access to capital, international markets, and advanced technology while allowing it to retain its brand identity and engineering legacy.

The global expansion of Butler is itself a motivational lesson in scaling a legacy company. From its humble Midwestern origins, Butler has now supplied projects in more than sixty countries. Factories in India, retail spaces in the Middle East, and aircraft hangars in Asia stand today as testaments to Butler’s global reach. Its story demonstrates that a company need not remain confined to its birthplace — with vision, adaptability, and partnerships, it can leave an imprint on skylines across the world.

At the heart of Butler’s century-long success has been its people. Generations of engineers, builders, and managers have carried forward a culture that prioritizes engineering excellence, customer trust, and openness to change. This culture has created not just a workforce but a family that believes in solving problems for clients and delivering value that lasts decades. Employees became brand ambassadors, and customers became lifelong partners, proving that the strongest foundation of any company is trust.

Butler’s story also carries profound lessons for entrepreneurs and leaders. First, big ideas often begin small — a workshop idea about roof panels became a billion-dollar industry. Second, innovation is not a luxury but a survival tool; in every crisis Butler faced, it responded with a new product or process that set it apart. Third, partnerships and collaborations can be powerful multipliers; the integration with BlueScope did not diminish Butler but elevated it to a new global platform. Fourth, legacy is built on quality — competitors who chased volumes faded away, while Butler, which insisted on standards, endured for over a century. And finally, adaptability is everything — from serving farmers in the 1900s to supplying mega-factories and green buildings in the 2000s, Butler’s ability to reinvent itself is the key reason for its continued relevance.

Looking ahead, Butler positions itself at the forefront of the green construction revolution. With global attention on climate change, the company is investing heavily in sustainable building systems, energy-efficient roofing, and low-carbon steel technologies. Just as it pioneered pre-engineered buildings over a century ago, Butler now aims to pioneer pre-engineered sustainability. It envisions a future where buildings are not only faster and stronger to build but also kinder to the environment, reducing carbon footprints while delivering economic value.

The motivational essence of Butler Manufacturing’s story is clear: innovation creates opportunity, resilience builds legacy, and vision shapes the future. From two brothers hammering steel panels in Kansas to a multinational leader transforming skylines, Butler shows that companies, like people, must evolve continuously or risk irrelevance. For entrepreneurs, business leaders, and dreamers, Butler offers one enduring inspiration: build solutions that outlast you. When you solve problems with integrity and foresight, your legacy stands tall — like steel, unbending against the storms of time.

Zamil Steel (Saudi Arabia)

The journey of Zamil Steel is one of the most powerful stories of ambition, resilience, and vision to come out of the Middle East. Founded in 1977 as part of the Zamil Industrial Investment Company, it was born during a period when Saudi Arabia was undergoing a massive transformation. Oil had brought wealth, but modernization demanded more than just oil fields; it demanded infrastructure, warehouses, airports, factories, and malls to house the new wave of economic growth. At that moment, Zamil Steel emerged with a clear purpose: to provide pre-engineered building solutions tailored for the region’s unique climate, geography, and developmental needs. The desert was not an easy place to build — scorching heat, sandstorms, and rapid urban expansion posed engineering challenges that many global companies hesitated to tackle. But Zamil Steel embraced these conditions, positioning itself as the local answer to a global problem.

The early years were difficult. Building trust in a region still unfamiliar with steel-based pre-engineered buildings required both education and demonstration. Zamil had to prove not just that steel buildings could work, but that they could outperform traditional methods in durability, speed, and cost-effectiveness. By focusing on climate-resilient designs and offering custom solutions rather than rigid templates, Zamil steadily won over clients across Saudi Arabia. Once it established credibility at home, it looked outward. By the mid-1980s and 1990s, Zamil Steel had become a regional force, exporting building solutions to Bahrain, Kuwait, and the UAE. Each successful project became a calling card that showed the Gulf and beyond that PEB systems were the future of industrial, commercial, and logistics construction.

Zamil’s growth was not fueled by ambition alone; it was driven by scale and innovation. One of the defining moments of its rise was the establishment of its massive manufacturing facility in Dammam, Saudi Arabia. With a monthly production capacity that rivaled the largest plants in the world, Zamil Steel could execute projects that smaller competitors simply could not handle. This gave it an edge in bidding for mega-projects, including industrial parks, oil refineries, and defense warehouses. By scaling up its operations, Zamil sent a message to the global construction industry: the Middle East was not only a consumer of modern infrastructure but also a creator. Its ability to handle vast projects positioned it as a natural partner for governments and corporations looking to expand quickly in emerging markets.

From these strong regional foundations, Zamil launched its global journey. By the turn of the millennium, it had established a presence in over 90 countries, exporting not just steel buildings but a philosophy of reliability, speed, and customer-first engineering. Its projects ranged from malls in Asia to industrial warehouses in Africa, and from logistics centers in Eastern Europe to iconic facilities in the Middle East. What made Zamil different from global competitors was its balance between cost-effectiveness and high-quality standards. Clients in developing markets often struggled with the expensive packages offered by Western firms, but Zamil could deliver world-class PEB solutions at a price point that matched local budgets without compromising durability. This mix of affordability and reliability became its greatest competitive weapon.

Of course, the road was not without obstacles. Global steel price fluctuations, oil market collapses, and recessions in the 1980s, 1990s, and 2000s constantly threatened Zamil’s margins and growth. The entry of Asian giants with cheaper offerings added intense competition. Yet, rather than retreating, Zamil adopted a threefold strategy: diversify, localize, and innovate. Diversification took the form of expanding beyond PEBs into structural steel, towers, and solar support systems. Localization meant setting up plants outside Saudi Arabia, in countries such as Vietnam, Egypt, and the UAE, to reduce shipping costs and provide faster regional service. Innovation was constant, from adopting the latest design software to implementing lean manufacturing processes that cut waste and improved productivity. This ability to adapt to changing market dynamics without losing focus on core values is one of the defining lessons of Zamil Steel’s journey.

What truly powered Zamil’s success, however, was its culture. While many Middle Eastern firms relied heavily on expatriate talent, Zamil invested in training local engineers and managers. This blend of global expertise and regional identity created a workforce that was not only technically competent but also deeply committed to the company’s mission of contributing to national and regional growth. Leadership at Zamil emphasized long-term partnerships over short-term profits, ensuring that clients returned project after project. The company’s reputation was not built overnight but through decades of delivering on promises and building trust across borders.

For entrepreneurs and leaders, the story of Zamil Steel offers several powerful lessons. First, align with your nation’s transformation — Zamil grew by riding the wave of Saudi Arabia’s modernization. Second, solve problems others ignore — desert climates and emerging markets presented challenges, but solving them gave Zamil credibility and competitive advantage. Third, scale matters — by building one of the world’s largest PEB facilities, Zamil ensured it was always considered for the biggest projects. Fourth, adaptation is survival — in a volatile region, the ability to diversify and innovate kept Zamil relevant even as global conditions shifted. Finally, culture is the invisible engine — investing in people created loyalty, pride, and long-term success that no amount of technology alone could achieve.

Looking ahead, Zamil Steel is positioning itself to ride another wave of transformation: sustainability. With Saudi Arabia’s Vision 2030 aiming to reduce oil dependency and build smart, green cities, Zamil is channeling resources into energy-efficient designs, solar-ready roofing systems, and digital construction technologies like Building Information Modeling (BIM). The company understands that the future of PEB is not only about faster and cheaper construction but also about sustainable and environmentally responsible solutions. Once again, it is preparing to lead the next chapter of industrial construction.

Ultimately, the story of Zamil Steel is not just about steel, buildings, or markets. It is about vision and courage — the courage to start something new in an untested industry, the vision to scale beyond borders, and the resilience to survive volatility without losing focus. It is proof that companies born in challenging environments can rise to global leadership if they innovate, adapt, and stay true to their mission. For business leaders and dreamers, Zamil Steel’s legacy is a reminder that even in the harshest deserts, ambition can grow into something that shapes skylines across continents.

BlueScope Buildings (Australia/USA)

The story of BlueScope Buildings is a story of transformation, resilience, and strategic vision that connects two worlds — the industrial spirit of Australia and the engineering innovation of the United States. BlueScope’s roots trace back to 1885, when John Lysaght & Co. began as a small galvanizing plant producing corrugated iron in Australia. Over time, the company grew into one of the most recognized names in steel across the Asia-Pacific. But the modern identity of BlueScope Buildings took shape in 2002, when the steel division of BHP Billiton was spun off to create BlueScope Steel, an independent company headquartered in Melbourne. This separation gave the company freedom, focus, and ambition. It quickly positioned itself not merely as a steel manufacturer but as a global leader in pre-engineered building solutions, roofing, and cladding systems. The leap from a regional steel supplier to an international construction powerhouse required courage, partnerships, and a relentless drive to adapt to global demands.

A major turning point in BlueScope’s journey came when it acquired Butler Manufacturing, the pioneering American pre-engineered building company founded in 1901. This acquisition in 2004 was not just a corporate deal; it was a marriage of heritage and innovation. Butler brought with it over a century of experience in pre-engineered buildings, an established customer base in the United States, and a legacy of trust. BlueScope, on the other hand, brought resources, global networks, and an appetite for expansion. Together, they created BlueScope Buildings North America, a division that could claim leadership not only in Australia but also in the world’s largest construction market — the U.S. This merger became a textbook case of how global companies can combine complementary strengths to create a stronger, more resilient entity.

What sets BlueScope apart is its ability to think both globally and locally. From its Australian headquarters, the company has built a presence in more than 17 countries, including China, India, Vietnam, Malaysia, and across North America. Each market presented different challenges — regulatory hurdles, cost pressures, local construction traditions, and sustainability demands. Yet BlueScope adapted by localizing production facilities, investing in community engagement, and offering solutions tailored to each region’s needs. In Asia, for example, it focused on cost-effective yet durable solutions to serve fast-growing industrial zones. In the U.S., it leveraged Butler’s premium reputation to target corporate giants needing reliable large-scale PEBs. This two-speed strategy — premium solutions in developed markets and affordable, scalable solutions in emerging ones — gave BlueScope a wide footprint unmatched by many competitors.

BlueScope’s growth was never just about selling steel buildings; it was about constant innovation. The company invested heavily in R&D, developing energy-efficient roofing systems, advanced coatings that extended the life of steel in corrosive environments, and modular designs that sped up construction timelines. Products such as COLORBOND® steel and ZINCALUME® steel became industry benchmarks, known worldwide for their durability, aesthetics, and sustainability. These innovations helped BlueScope win the loyalty of architects, contractors, and governments alike, proving that steel buildings could be not only functional but also environmentally responsible and visually appealing.

The company also demonstrated resilience in the face of adversity. The global financial crisis of 2008 hit the construction industry hard, with projects being canceled and steel demand plummeting. BlueScope faced painful losses, plant closures, and restructuring. Yet, instead of collapsing, it made tough but strategic decisions — cutting costs, focusing on core markets, and pivoting toward growth regions in Asia. This period tested BlueScope’s endurance, but it emerged leaner, stronger, and more focused. The lesson here is clear: survival in global industries often depends on making bold decisions during crises, even when those decisions are unpopular.

Another defining strength of BlueScope is its deep commitment to sustainability and community responsibility. Long before ESG (Environmental, Social, and Governance) became a global corporate mantra, BlueScope was embedding sustainability in its operations. It reduced carbon emissions in steel production, recycled materials at scale, and introduced energy-efficient building systems. The company positioned itself not just as a steel producer but as a partner in building green economies. In fact, BlueScope’s climate action roadmap includes ambitious goals to achieve net-zero emissions by 2050, reflecting its recognition that the future of construction lies in sustainability. For customers, this meant more than just buildings; it meant confidence that they were investing in solutions aligned with the future of the planet.

But what truly elevates BlueScope’s story to an inspirational case study is its people and culture. From engineers in Melbourne to factory workers in Kansas City, from managers in Shanghai to project teams in India, BlueScope has cultivated a workforce united by innovation, safety, and customer service. Its leaders emphasize inclusivity, training, and empowerment, believing that employees are not just workers but custodians of the brand. This philosophy built a sense of ownership across its workforce, ensuring that every project — whether a factory in Texas or a logistics hub in Thailand — carried the same standard of quality and trust.

The motivational lessons from BlueScope’s journey are powerful. First, heritage can be a foundation, not a limit; from its 19th-century roots, the company used history as a platform to grow globally. Second, partnerships multiply strengths; acquiring Butler turned BlueScope from a regional giant into a global powerhouse. Third, innovation is non-negotiable; investing in energy-efficient, durable, and sustainable products gave it an edge over cheaper competitors. Fourth, resilience defines leadership; surviving financial crises and steel downturns proved that adaptability is as important as ambition. Finally, purpose sustains growth; by focusing on sustainability and community responsibility, BlueScope created not just profits but long-term trust.

Looking to the future, BlueScope positions itself at the intersection of construction, sustainability, and technology. It aims to be a leader in low-carbon steel, smart PEB systems, and digital construction tools. As urbanization accelerates, especially in Asia and Africa, demand for fast, efficient, and eco-friendly construction will soar — and BlueScope is prepared to meet that demand. The company’s story is not simply about steel; it is about building the framework for modern economies, enabling growth, and inspiring confidence that progress can be both profitable and sustainable.

In conclusion, BlueScope Buildings is more than a steel producer; it is a global builder of trust, innovation, and resilience. From its modest Australian beginnings to its commanding global presence, it demonstrates that companies can expand across continents without losing their soul. It teaches entrepreneurs and leaders that adaptability, partnerships, and a clear sense of purpose are the cornerstones of lasting success. For anyone dreaming of building something larger than themselves, BlueScope’s journey offers a timeless lesson: when you combine vision with resilience and values, you don’t just build structures — you build legacies.

Kirby Building Systems (Kuwait/India/Global)

The story of Kirby Building Systems is a story of how vision, timing, and perseverance can transform a regional startup into a global brand. Founded in 1976 in Kuwait, Kirby began with a simple mission: to provide pre-engineered steel buildings to a market that was still relying heavily on traditional construction methods. At the time, the Middle East was at the beginning of an oil-driven infrastructure boom, and the need for warehouses, factories, and logistics hubs was increasing rapidly. Kirby recognized this wave before most others did. Instead of focusing on conventional structures, it offered a faster, cheaper, and more scalable alternative: pre-engineered buildings designed in factories and assembled on-site. It was an idea that fit perfectly with the speed and scale of development sweeping across the Gulf.

In its early years, Kirby faced enormous challenges. Pre-engineered buildings were still a new concept in the region, and convincing clients of their durability and long-term value required relentless education and trust-building. Yet Kirby persevered, completing projects one after another and slowly proving that PEB systems could withstand desert climates, sandstorms, and the logistical challenges of rapid industrialization. By the 1980s, Kirby had established itself as a serious player in the Middle East construction sector. Its commitment to quality and its ability to deliver large projects on tight deadlines won it repeat business and positioned it as a partner in the region’s modernization.

But Kirby’s ambition was never limited to Kuwait or the Gulf. As the 1990s approached, the company saw another opportunity: India. India was undergoing liberalization, opening its economy to foreign investments and accelerating its industrial development. Warehousing, automotive plants, and logistics infrastructure were in high demand. Sensing this, Kirby entered the Indian market early, setting up one of the first large-scale PEB facilities in Hyderabad in 1999. This was a bold move at a time when Indian construction was still dominated by concrete and brick. Yet Kirby bet on the future, believing that Indian industries would soon need faster, larger, and more efficient building solutions. History proved Kirby right. Over the next two decades, it became one of the most recognized names in India’s PEB industry, delivering thousands of projects ranging from automobile plants to massive logistics parks.

Kirby’s success has been driven by its scalability and global mindset. The company established a strong presence across Asia, Africa, and the Middle East, completing projects in more than 70 countries. Its manufacturing facilities in Kuwait, India, and Vietnam gave it a truly international footprint, allowing it to serve multiple regions without being constrained by shipping costs or time delays. This ability to scale operations and establish localized presence gave Kirby an edge over smaller competitors who could not operate beyond their home countries.

Innovation has also been at the heart of Kirby’s journey. From the beginning, the company invested in advanced design software, precision manufacturing, and modular systems that allowed it to deliver customized solutions for clients across industries. Whether it was a small warehouse for an SME in Africa or a giant factory for a multinational in India, Kirby offered flexibility, quality, and cost-efficiency. Its projects included some of the largest PEB structures in Asia, showcasing its ability to execute complex, large-scale designs. Moreover, Kirby embraced lean manufacturing practices to improve efficiency, reduce waste, and pass savings on to customers, reinforcing its reputation as a reliable and value-driven partner.

Like all global companies, Kirby has faced volatility and competition. Steel price fluctuations, regional recessions, and the rise of new competitors in Asia challenged its margins. Yet Kirby survived by staying true to its principles: customer-first service, uncompromising quality, and strategic diversification. During downturns, it expanded into new geographies. When competitors offered cheaper but lower-quality structures, Kirby doubled down on its engineering standards. Its persistence showed clients that reliability was worth paying for, ensuring long-term loyalty in a cost-sensitive industry.

What makes Kirby’s story truly motivational is its ability to blend global ambition with local relevance. In India, for example, it partnered with leading industrial firms to design and deliver custom solutions that matched local needs while still maintaining international standards. In Africa, it became a trusted supplier for logistics and trade hubs, contributing to the continent’s industrial growth. In the Middle East, it continued to reinforce its brand as a premium player in oil and gas infrastructure. Everywhere it went, Kirby adapted, listened, and delivered — traits that made it stand out in a crowded field.

The cultural fabric of Kirby has also been key to its success. Leadership emphasized collaboration, training, and customer focus. Engineers and managers were empowered to innovate and adapt, creating a workforce that was not only technically skilled but also deeply motivated to build trust with clients. This people-centric culture ensured consistency in quality and service, even as the company expanded across continents. Kirby understood early that buildings are not just steel and bolts; they are long-term investments for clients, and delivering trust was as important as delivering a structure.

The lessons from Kirby’s journey are clear and inspiring. First, timing is everything — entering the Gulf in the 1970s and India in the 1990s positioned it ahead of the curve in booming markets. Second, scale creates opportunity — by building large plants and spreading across geographies, it could handle projects others could not. Third, innovation secures survival — advanced software, modular design, and lean manufacturing kept Kirby competitive even during downturns. Fourth, localization wins trust — setting up in India, Vietnam, and Africa showed clients it was committed to their markets, not just exporting from afar. Finally, resilience defines leadership — through oil shocks, steel crises, and recessions, Kirby endured and grew stronger.

Looking to the future, Kirby is aligning itself with global trends of sustainability, digital design, and smart construction. With industries demanding green buildings, Kirby is investing in energy-efficient systems, solar-integrated roofs, and recyclable steel technologies. As logistics and e-commerce drive demand for modern warehouses, Kirby is well positioned to deliver the next generation of PEBs that are faster, smarter, and greener.

Ultimately, the story of Kirby Building Systems is more than a corporate history; it is a lesson in foresight, courage, and endurance. From a modest Kuwaiti venture to a multinational brand serving 70 countries, Kirby proves that companies from emerging markets can compete globally if they dare to think big, adapt constantly, and stay rooted in their values. For entrepreneurs and leaders, Kirby’s journey is proof that true growth comes not from following trends but from anticipating them, and not from chasing short-term wins but from building long-term trust.

Tata BlueScope Steel (India)

The story of Tata BlueScope Steel is not just about steel and construction; it is about partnership, trust, and the fusion of two powerful legacies. Established in 2005 as a joint venture between Tata Steel, one of India’s oldest and most respected industrial groups, and BlueScope Steel Limited, an Australian giant known for its advanced steel technologies, Tata BlueScope was born at a time when India was racing toward rapid industrialization. The Indian economy had entered an era of unprecedented growth after liberalization, with infrastructure, logistics, and industrial projects multiplying across the nation. Yet the construction industry struggled with outdated methods, long timelines, and rising costs. It was in this gap that Tata BlueScope positioned itself as a solution, offering pre-engineered building systems, world-class roofing and cladding solutions, and steel that met international benchmarks of durability and sustainability. The venture was more than a corporate collaboration; it was the meeting of two philosophies — Tata’s values of trust, integrity, and nation-building combined with BlueScope’s engineering innovation and global outlook.

From the very beginning, Tata BlueScope focused on becoming more than just another steel manufacturer. Its mission was clear: to revolutionize the way India built its factories, warehouses, commercial complexes, and infrastructure. It brought to India products like COLORBOND® steel and ZINCALUME® steel, which were already global benchmarks for durability and aesthetics. These products changed the perception of steel structures in India. Steel was no longer viewed as just functional but also as a material that could be sustainable, stylish, and long-lasting. The company’s pre-engineered building division, under the brand BUTLER® Building Systems, began delivering industrial sheds, logistic hubs, and large-scale facilities that were faster to erect, more cost-efficient, and more reliable than traditional concrete construction. By marrying global technology with local execution, Tata BlueScope quickly carved out a leadership position in the Indian PEB market.

Like any growing company, Tata BlueScope faced its share of challenges. India is a highly cost-sensitive market, and many competitors offered cheaper but lower-quality PEB solutions. Convincing clients that quality and longevity justified a premium price was not easy. Yet, Tata BlueScope’s reputation benefited from the credibility of its parent companies. The Tata name, synonymous with trust and nation-building in India, reassured customers. At the same time, BlueScope’s global engineering standards added confidence that projects would stand the test of time. With this dual assurance, Tata BlueScope positioned itself as a partner of choice for multinationals, government projects, and leading Indian corporations. Over time, this focus on value over price created long-term loyalty among its clients.

The company’s growth was also fueled by its deep commitment to sustainability and innovation. Long before green building became a mainstream requirement, Tata BlueScope introduced roofing and cladding systems that reduced heat absorption, lowered energy consumption, and increased building life cycles. Its COLORBOND® steel, for example, was marketed not just as a product but as a sustainable solution that supported India’s climate and energy challenges. This focus on environmental responsibility resonated strongly with corporations looking to align with global sustainability standards. In many ways, Tata BlueScope was ahead of its time, anticipating trends in energy efficiency and environmental stewardship that would later become mandatory in construction.

The company’s culture also reflects the ethos of its parent organizations. It inherited Tata’s values of ethical business practices, respect for people, and a commitment to community development, while adopting BlueScope’s global best practices in safety, training, and innovation. Employees were empowered to think beyond traditional limits, leading to a culture of innovation and ownership. Projects were not seen as transactions but as partnerships, where Tata BlueScope worked hand in hand with clients to understand their needs and deliver tailored solutions. This people-centric culture ensured that every project carried not just steel and engineering but also a sense of trust and reliability.

One of Tata BlueScope’s strengths has been its ability to balance global and local strategies. While it introduced international products and technologies, it localized them for Indian conditions. For example, its roofing and cladding systems were customized to withstand the country’s diverse climates, from scorching summers to heavy monsoons. Its pre-engineered buildings were tailored for industries like automotive, warehousing, logistics, and even agriculture, ensuring relevance across sectors. This combination of global standards and local customization became a unique differentiator, helping Tata BlueScope capture a significant share of the market.

The motivational lessons from Tata BlueScope’s journey are powerful. First, partnerships can create new possibilities. Alone, Tata or BlueScope could not have achieved the same impact in India, but together, they created a platform that brought the best of both worlds. Second, trust is a competitive advantage. In a market crowded with options, the credibility of the Tata name gave customers confidence to choose quality over cheap alternatives. Third, innovation ensures longevity. By introducing sustainable and energy-efficient products early, Tata BlueScope future-proofed its business and earned a reputation as a responsible leader. Fourth, local adaptation matters. Global products and technologies succeed only when tailored to local needs, and Tata BlueScope mastered this balance. Finally, values are as important as vision. By adhering to ethics, safety, and community responsibility, Tata BlueScope proved that business growth can go hand in hand with social responsibility.

Looking ahead, Tata BlueScope is positioning itself for the next era of growth in India. With the rise of e-commerce, data centers, logistics hubs, and smart cities, the demand for modern, fast, and sustainable building solutions will only grow. The company is investing in advanced digital design tools, automation in manufacturing, and new sustainable materials to meet this demand. Its role will not just be that of a supplier but of a partner in India’s development journey, contributing to the nation’s infrastructure, economy, and sustainability goals.

Ultimately, the story of Tata BlueScope Steel is a story of synergy — the synergy of tradition and modernity, local needs and global expertise, and profit with responsibility. It shows how joint ventures, when rooted in shared values and clear vision, can become engines of transformation. From its inception in 2005 to its current stature as a leader in India’s PEB and steel solutions market, Tata BlueScope has proved that success is not about speed alone but about building something enduring. For leaders and entrepreneurs, the lesson is clear: when you combine trust with innovation and ground your business in values, you don’t just build structures, you build legacies that inspire generations.

Nucor Building Systems (USA)

The story of Nucor Building Systems is inseparable from the story of its parent company, Nucor Corporation, which has long been celebrated as one of America’s most innovative and resilient steelmakers. Born out of a struggling conglomerate in the mid-20th century, Nucor reinvented itself into the most efficient, profitable, and employee-driven steel company in the United States. It was in 1987 that Nucor formally created its Building Systems division, with a vision to expand its expertise beyond producing steel into delivering pre-engineered building solutions. The idea was simple but powerful: if Nucor already manufactured some of the best steel in the world, why not transform that steel into complete building systems that delivered quality, speed, and cost-efficiency? This forward integration became a defining step that established Nucor Building Systems as a trusted name in the PEB industry.

From the outset, Nucor Building Systems positioned itself differently from competitors. While many companies in the PEB space focused on standardization, Nucor emphasized customization. It understood that clients — whether building a distribution center, manufacturing facility, or retail complex — wanted structures tailored to their exact needs rather than rigid templates. With its strong engineering base, Nucor delivered flexible solutions that combined structural efficiency with architectural freedom. This approach won it a loyal customer base, particularly in industries that demanded large-scale, specialized facilities. More importantly, by tying its operations closely with Nucor’s steel production, the Building Systems division guaranteed consistent quality, competitive pricing, and a seamless supply chain.

What made Nucor unique, however, was not only its products but its culture. Nucor famously adopted a people-first, performance-driven model that empowered employees and created one of the most motivated workforces in the industry. The company has never laid off an employee due to market downturns, a rare commitment in the volatile steel business. Instead, it introduced profit-sharing schemes, decentralized decision-making, and open communication policies. Every worker, from plant floor operators to senior managers, had a stake in the company’s success. This culture of trust and accountability filtered down into Nucor Building Systems, where engineers and builders felt ownership of their projects and took pride in delivering excellence. For clients, this translated into reliability, consistency, and innovation.

Like its parent company, Nucor Building Systems thrived on innovation and efficiency. It embraced advanced design software and manufacturing processes that allowed it to produce PEB systems faster and with less waste. It invested heavily in lean practices, ensuring that every stage of the process — from design to fabrication to assembly — added value. The division became known for structures that were not only strong and durable but also energy-efficient and environmentally responsible. In fact, sustainability became one of Nucor’s defining attributes. As one of the world’s largest recyclers, Nucor used recycled scrap to produce its steel, ensuring that every building delivered by Nucor Building Systems carried an inherent environmental advantage. At a time when sustainability was becoming a global priority, this gave the company a distinct competitive edge.

The global financial crisis of 2008 tested Nucor and its Building Systems division severely. Construction projects were delayed or canceled, steel demand plummeted, and many competitors collapsed under financial pressure. Yet, Nucor remained resilient. True to its philosophy, it did not lay off employees, instead using the downturn to retrain, retool, and prepare for recovery. By maintaining its workforce and culture intact, Nucor emerged stronger when demand returned. For Nucor Building Systems, this period reinforced its reputation as a partner that stood by its employees and its customers during hard times, not just when profits were easy. It proved that resilience and long-term thinking matter more than short-term gains.

Over the years, Nucor Building Systems expanded across the United States with multiple manufacturing plants, ensuring regional proximity to customers and reducing lead times. Its structures became part of the American industrial landscape, from distribution warehouses to automotive plants, agricultural facilities, and community centers. Each project carried the mark of Nucor’s values: quality, reliability, and innovation. Clients valued not only the technical excellence of the buildings but also the peace of mind that came from working with a company built on integrity.

The motivational lessons from Nucor Building Systems are profound. First, people are the foundation of success. Nucor’s commitment to its employees created a culture of loyalty and excellence that no competitor could replicate. Second, crises are opportunities for reinvention. Instead of shrinking during downturns, Nucor invested in its workforce and emerged stronger. Third, sustainability is not a buzzword but a business model. By recycling scrap into steel, Nucor aligned profitability with responsibility decades before ESG became fashionable. Fourth, integration creates strength. By linking steel production with building systems, Nucor ensured control, consistency, and efficiency throughout the value chain. And finally, trust is the ultimate competitive advantage. By standing by employees and clients alike, Nucor created a reputation that endures beyond market cycles.

Looking to the future, Nucor Building Systems is positioning itself to meet the demands of a changing construction industry. With e-commerce driving a surge in warehouses, renewable energy requiring specialized facilities, and data centers becoming the backbone of the digital economy, the demand for customized, large-scale, and sustainable PEB systems is higher than ever. Nucor’s ability to combine high-quality steel, innovative designs, and a people-first culture makes it uniquely equipped to capture this growth. At the same time, its commitment to reducing carbon emissions and advancing green technologies ensures that it remains aligned with global sustainability goals.

Ultimately, the story of Nucor Building Systems is a story of how values can be a competitive weapon. In an industry often dominated by cost battles and short-term wins, Nucor has shown that putting people first, innovating relentlessly, and building with integrity create long-term success. From its birth in 1987 to its present-day position as one of America’s leading PEB providers, Nucor Building Systems has embodied the principle that companies are strongest when they combine vision with values. For entrepreneurs, leaders, and dreamers, its journey is a reminder that success is not only about building structures but also about building trust, culture, and resilience that withstand the tests of time.

Everest Industries (India)

The story of Everest Industries is one of resilience, reinvention, and relevance in a rapidly changing industrial landscape. Founded in 1934, Everest began as a company producing fiber cement roofing sheets, serving rural India and small industries with affordable, durable solutions for shelter. At that time, India was still under colonial rule, its industrial sector limited, and its infrastructure underdeveloped. Everest was among the few companies that envisioned an India where modern, industrial-grade materials could reach the common farmer, trader, or small manufacturer. For decades, its cement sheets became almost synonymous with roofing in villages and towns, establishing Everest as a household name. Yet, what makes Everest’s journey remarkable is not its early success in roofing but its ability to continuously reinvent itself over nearly a century to remain relevant in a construction industry that evolved dramatically.

By the latter half of the twentieth century, Everest had built a solid reputation in India’s building materials market. Its roofing products were everywhere, serving millions of small structures across the subcontinent. However, the dawn of liberalization in the 1990s brought new challenges. India was opening its economy, foreign companies were entering, and consumer preferences were shifting toward modern, versatile materials. A company that clung only to its old business model risked obsolescence. Everest faced a stark choice: remain a traditional roofing sheet company or transform into a broader construction solutions provider. It chose the harder path — reinvention. This strategic decision marked the beginning of Everest’s evolution from a roofing company into a diversified leader in roofing, boards, panels, and, eventually, pre-engineered buildings (PEBs).

The move into pre-engineered buildings was bold but logical. India’s rapid industrialization in the 2000s created massive demand for warehouses, factories, and commercial buildings that could be built quickly and cost-effectively. Everest, already trusted as a durable materials provider, leveraged this credibility to enter the PEB sector. It invested in advanced manufacturing facilities and design capabilities, building a strong presence in industrial and commercial construction. Suddenly, Everest was no longer just the provider of rural rooftops; it was now delivering entire logistics hubs, industrial sheds, and corporate facilities. This transformation was not easy, but it showed the company’s ability to anticipate market needs and act decisively.

Everest’s foray into PEB was not just about chasing growth but also about innovation and adaptability. It introduced lightweight boards and panels, eco-friendly roofing, and modular systems that catered to modern construction demands. By combining its legacy in cement-based products with steel structures and modern materials, it created a portfolio that addressed diverse customer needs. This ability to bridge old and new made Everest unique in the Indian market. While competitors focused solely on steel PEBs, Everest positioned itself as a holistic building solutions company, capable of supplying both materials and complete structures.

The company’s resilience has been tested many times. Economic downturns, raw material price fluctuations, and competitive pressures from both multinational corporations and low-cost domestic players often threatened its margins. Yet Everest’s strategy of diversification and quality focus kept it afloat. During slowdowns, it leaned on its strong base of roofing and boards; during booms, it expanded aggressively in PEBs and advanced products. This balance between legacy products and modern solutions acted as a stabilizer, allowing the company to survive cycles that might have destroyed less adaptive businesses.

What makes Everest’s story motivational is its deep commitment to India’s development journey. While many companies chased only high-value urban projects, Everest continued to serve rural and semi-urban markets with affordable products even as it expanded into cutting-edge PEB systems for industrial giants. This dual commitment — to inclusivity and innovation — reflects a philosophy that growth must be sustainable and broad-based. It is a reminder that companies can modernize without abandoning the communities that built their foundation.

At the cultural level, Everest’s strength has been its ability to blend tradition with modernity. Its leadership fostered a culture of integrity, long-term relationships, and continuous improvement. Employees were encouraged to take pride in the company’s legacy while also embracing new technologies and approaches. This culture created a sense of continuity even as Everest transformed its product portfolio. Clients, in turn, trusted Everest not just because of its products but because of its reputation for reliability and ethical practices — a rare but valuable commodity in the construction industry.

The lessons from Everest Industries are clear and inspiring. First, reinvention is survival. A company that began with cement sheets in the 1930s has managed to thrive nearly a century later by constantly evolving. Second, diversification creates resilience. By balancing legacy products with modern innovations, Everest built a cushion against market volatility. Third, brand trust is a long-term asset. Decades of delivering quality created loyalty that competitors could not easily replicate. Fourth, inclusive growth builds relevance. By serving both rural and urban markets, Everest remained connected to the broad spectrum of India’s development. And finally, vision matters as much as execution. Everest’s willingness to bet on new businesses like PEB at the right time ensured its relevance in a modernizing economy.

Looking forward, Everest is poised to continue its transformation. With India’s growing focus on infrastructure, smart cities, and logistics, the demand for modern PEB systems is expanding rapidly. At the same time, sustainability is becoming a non-negotiable requirement. Everest is aligning with these trends by investing in eco-friendly materials, energy-efficient systems, and green construction practices. By integrating sustainability into its DNA, Everest is not just preparing for the future but actively shaping it.

Ultimately, the story of Everest Industries is a powerful reminder that companies, like individuals, must continuously evolve to stay relevant. It shows that legacies are not preserved by resisting change but by embracing it. From a humble roofing sheet manufacturer in pre-independence India to a diversified building solutions provider in the twenty-first century, Everest has demonstrated the courage to reinvent, the discipline to adapt, and the vision to grow. For entrepreneurs and leaders, Everest’s journey is an inspiration: no matter how old your company or how entrenched your product, there is always room to transform and thrive. The key lies in having the courage to let go of the past while carrying forward the values that built it. Everest’s legacy proves that reinvention is not only possible but also the surest path to long-term success.

PEB Steel Buildings Co. Ltd. (Vietnam/Asia)

The story of PEB Steel Buildings is a testament to how a company born in an emerging economy can rise to compete on the global stage through vision, adaptability, and relentless focus on quality. Established in 1994 and headquartered in Ho Chi Minh City, Vietnam, PEB Steel entered the market at a time when Vietnam was just beginning its journey of economic liberalization. The country had recently shifted toward market-oriented reforms, foreign investments were slowly flowing in, and industries such as textiles, footwear, and manufacturing were expanding. Yet Vietnam lacked modern infrastructure and industrial building systems that could support this rapid transformation. Conventional brick-and-mortar construction was slow, expensive, and ill-suited for the speed at which factories and warehouses needed to be built. Into this gap stepped PEB Steel, offering a solution that was faster, cost-effective, and scalable: pre-engineered steel buildings.

The company’s early years were not easy. As in many emerging markets, skepticism about steel structures was high, and clients were hesitant to move away from traditional construction methods. PEB Steel had to prove itself by delivering projects that not only met but exceeded customer expectations in terms of durability, speed, and cost savings. Its breakthrough came as foreign companies set up factories in Vietnam and demanded world-class infrastructure. By meeting the high standards of these multinationals, PEB Steel established credibility quickly. One successful project led to another, and soon it became the trusted name for industrial and commercial facilities not just in Vietnam but across Southeast Asia.

PEB Steel’s strategy was always built on global vision with local execution. While headquartered in Vietnam, it operated with an international mindset, adopting global best practices in design, engineering, and project management. It introduced advanced design software, automated manufacturing processes, and quality control systems that matched those of leading global firms. This allowed PEB Steel to compete not just on price, which was often the advantage of emerging market players, but on quality and reliability. As a result, it attracted clients across industries such as automotive, electronics, logistics, and retail. Its projects soon spread beyond Vietnam to countries like Thailand, Cambodia, Myanmar, the Philippines, Bangladesh, and the Middle East, establishing PEB Steel as a regional powerhouse.

One of the keys to PEB Steel’s success was its focus on scalability and capacity building. Over the years, it invested heavily in state-of-the-art factories across Vietnam, increasing production capacity to handle large and complex projects. This ability to scale meant it could serve both small businesses needing warehouses and multinational giants requiring mega factories. For example, it supplied steel building solutions for industrial parks, logistics hubs, and even specialized facilities like cold storage units. By building manufacturing strength at home, PEB Steel reduced its dependency on imports and positioned itself as a competitive exporter in the region.

Like all companies in the construction sector, PEB Steel faced challenges from market volatility, competition, and economic downturns. The Asian financial crisis of the late 1990s and the global financial crisis of 2008 both slowed investments in construction. Steel price fluctuations added further strain. Yet PEB Steel demonstrated resilience. It doubled down on cost-efficiency, strengthened client relationships, and emphasized flexibility in its solutions. By focusing on long-term partnerships instead of short-term profits, it weathered downturns and emerged stronger. This adaptability became one of its defining strengths.

Culturally, PEB Steel created an organization that blended international professionalism with local pride. Its leadership invested in training Vietnamese engineers and technicians, creating a skilled workforce capable of delivering to global standards. At the same time, it fostered a culture of innovation, encouraging employees to find better ways to design and deliver projects. This empowerment created loyalty among employees and consistency in service to clients. For multinational clients operating in Vietnam, this was a major reassurance: they were dealing with a company that could combine local knowledge with international expertise.

The motivational lessons from PEB Steel’s journey are both inspiring and practical. First, emerging markets can produce global leaders. A company born in Vietnam, a country once overlooked in the global industrial map, became a regional force in PEB by aligning with economic reforms and foreign investments. Second, quality builds credibility. By refusing to compete on price alone and insisting on global-quality standards, PEB Steel earned trust from multinationals and governments alike. Third, capacity creates opportunity. By building large manufacturing facilities, the company could compete for projects that smaller firms could not handle. Fourth, resilience ensures survival. By adapting during crises and downturns, PEB Steel not only survived but expanded. Finally, people are the backbone. By investing in local talent and creating a culture of pride and professionalism, PEB Steel ensured long-term sustainability.

Looking ahead, PEB Steel is aligning with global trends of sustainability, digitalization, and smart construction. With climate change becoming a defining challenge of our times, the company is focusing on energy-efficient building designs, recyclable materials, and systems that reduce carbon footprints. It is also adopting digital design tools and Building Information Modeling (BIM) to increase precision and reduce construction time. With the rise of e-commerce, logistics, and data centers in Asia, demand for modern warehouses and specialized facilities is set to soar, and PEB Steel is well positioned to capture this growth. Its journey from a modest Vietnamese company to a regional leader shows that the future belongs to firms that combine vision with execution.

Ultimately, the story of PEB Steel Buildings is more than just corporate history; it is a story of confidence and possibility. It proves that companies from smaller economies can achieve global relevance if they dare to dream big, invest in quality, and remain resilient in adversity. From its beginnings in 1994 to its current status as one of Asia’s leading PEB companies, PEB Steel inspires entrepreneurs and leaders with a simple but powerful message: your origins do not define your destiny. With vision, adaptability, and commitment to excellence, any company, anywhere in the world, can rise to shape industries and inspire generations.

Qatar Steel Industries Factory (Qatar)

The story of Qatar Steel Industries Factory is deeply connected with the remarkable transformation of Qatar itself — from a modest Gulf nation into a global hub of infrastructure, energy, and innovation. Founded in 1980, at a time when Qatar was only beginning to tap into the potential of its vast oil and natural gas wealth, the company started with a simple mission: to provide reliable steel and structural solutions to support the nation’s growing infrastructure needs. In its earliest years, Qatar Steel Industries Factory focused on basic fabrication and supply of steel products for domestic construction. But what distinguished the company from its competitors was a clear vision: to align itself with the nation’s ambition and grow as Qatar grew. That alignment would prove to be the foundation for its rise as one of the region’s most trusted names in pre-engineered buildings and steel structures.

Qatar in the 1980s and 1990s was on the cusp of modernization. Roads, ports, airports, and industrial facilities were being built to diversify the economy beyond hydrocarbons. Demand for fast, reliable, and large-scale construction was unprecedented, and Qatar Steel Industries Factory stepped into this space with confidence. It developed expertise in pre-engineered buildings (PEBs), a relatively new concept for the region at the time. The company’s ability to deliver durable, climate-resistant steel structures quickly earned it recognition. The desert climate of Qatar, with its searing heat and corrosive conditions, posed significant challenges for construction, but the company engineered solutions that could withstand these extremes. Over time, what started as a domestic supplier evolved into a strategic partner for Qatar’s national projects, handling everything from industrial warehouses to commercial complexes.

The turning point for Qatar Steel Industries Factory came in the early 2000s, as the country began preparing for massive global events and infrastructure expansion. The announcement of FIFA World Cup 2022 was particularly transformative. Suddenly, Qatar needed not only stadiums but also hotels, malls, logistics hubs, and transportation systems at a scale never before seen in the Gulf. Qatar Steel Industries Factory rose to the challenge, contributing steel structures and PEB systems for various mega projects that became part of Qatar’s global showcase. These projects were not just about construction; they were symbols of national pride. Every facility delivered was a demonstration of Qatar’s ability to stand alongside the world’s most advanced nations, and the company became part of that story.

What made Qatar Steel Industries Factory stand out was its commitment to innovation, scalability, and flexibility. The company invested in advanced design and manufacturing systems, enabling it to execute both small and mega projects with equal precision. Whether it was a logistics warehouse for local businesses or structural steel for international corporations, the company provided customized solutions that met exact client requirements. This flexibility made it the partner of choice not only for domestic clients but also for international investors who were entering Qatar’s booming economy. By continuously upgrading its capabilities, it positioned itself as a forward-looking company that could match global standards while retaining local expertise.

Of course, the path was not free of challenges. The steel industry worldwide is vulnerable to price volatility, and the Gulf region is no exception. Fluctuations in global commodity markets, the 2008 financial crisis, and regional competition all tested the company’s resilience. Yet Qatar Steel Industries Factory responded with determination. It diversified its offerings to include structural steel, towers, and turnkey PEB solutions. It improved efficiency by adopting lean manufacturing practices and investing in workforce training. And it built long-term partnerships with government agencies and contractors, ensuring stability even during downturns. These strategies helped the company weather global storms while continuing to expand its footprint.

A crucial driver of success has been the company’s alignment with Qatar’s national vision. Qatar National Vision 2030, which emphasizes sustainable development, economic diversification, and infrastructure excellence, provided a roadmap for the company’s growth. Qatar Steel Industries Factory embraced this vision by incorporating sustainability into its operations, adopting eco-friendly practices, and offering energy-efficient building systems. Its commitment to responsible growth mirrored the nation’s ambition to modernize without compromising environmental responsibility. This alignment not only secured government trust but also enhanced its reputation among international partners who increasingly demand sustainable construction practices.